设计简介

摘要:塑料工业是当今世界上增长最快的工业门类之一,而注塑模具是其中发展较快的种类,因此,研究注塑模具对了解塑料产品的生产过程和提高产品质量有很大意义。

在注塑产品开发中,模具的设计和制造决定塑料件的质量和成本。综观国内外先进制造技术的现状和发展,不难看出数字化制造技术是先进制造技术的核心技术。随着制造业的国际化,中国正逐渐成为制造业大国,

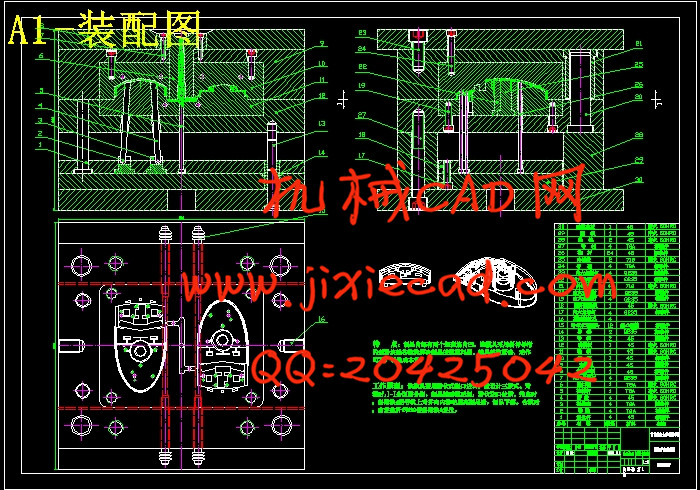

本文探讨了基于Mastercam平台实现注塑模具CAD/CAM的方法和途径,并以鼠标上盖为例,实现了注塑模具CAD/CAM过程。利用Mastercam软件提供CAM数控加工模块,完成了数控加工的全过程。本文详细介绍了注射模具浇注系统、温度调节系统和顶出系统的设计过程,鼠标上盖零件的结构及工艺性,确定该塑件的注塑成型方案并进行了注塑模设计方面的相关计算。CAD/CAM技术在模具行业中的应用,大大减少了模具设计制造的周期,取得了显著的经济效益,从根本上改变了传统的模具生产方式。

本文介绍了CAM技术在鼠标上盖注塑模具制造的NC加工中的应用过程,包括曲面建模、加工路径的选择、刀具轨迹计算等,并对该套模具NC加工编程的特殊性及其工艺处理作了分析。本文主要介绍了Mastercam模块的作用、加工能力和特点以及Mastercam加工类型和加工工艺简介,并用Mastercam实现仿真加工。

关键词:注塑模 CAD/CAM Mastercam

Abstract:Now the plastics industry is one of the growing quickest industry classes in the world, but the injection mold is develops the quick type. Therefore, There have biggist significance to research injection mold to understood that the plastic of production process and improve the product quality.A comprehensive survey of modern manufacturing technology indicated, that the digitized manufacturing is the key technique of advanced manufacturing technology.Our country is becoming a big factory.

Based on Mastercam,the author present the method for Mastercam to achieve mould CAD/CAM, and take the mouse-up as an example, describe the process of UG mould CAD/C AM in detail.The authors complete the NC manufacturing of mold’s core in Mastercam software.This design introduced the cold flow channel injection evil spirit mold pours the system, the temperature control system and goes against the system the design process, the analyzing of the structure and crafts of the mouse-up shells, deciding the way of the injecting and doing certain calculation relating to the injecting-mold. The using of CAD/CAM technology in mold industry decreases the time of mold-making with the result of increasing economies efficiency and ultimately exchanging the mode of traditional model-making.

The application procedure of CAM in the mouse-up injection mold NC manufacturing is introduced in the paper.The procedure includes surface modeling, manufacture path selection, tool path calculating.An analyses of the characteristic of NC program and the dispose of technics about the mouse-up-mold is made. The article mainly introduce the friction、capacity and term of Mastercam and manufacturing types and technics of Mastercam, has stress on the integration of the core of the mouse-up-mould,and realize its emulation.

Key word:Injection Mould CAD/CAM Mastercam

引言 1

1 绪论 2

1.1 我国模具企业技术现状及发展趋势 2

2.1 本次毕业设计应达到的目的 5

2 设计任务书 5

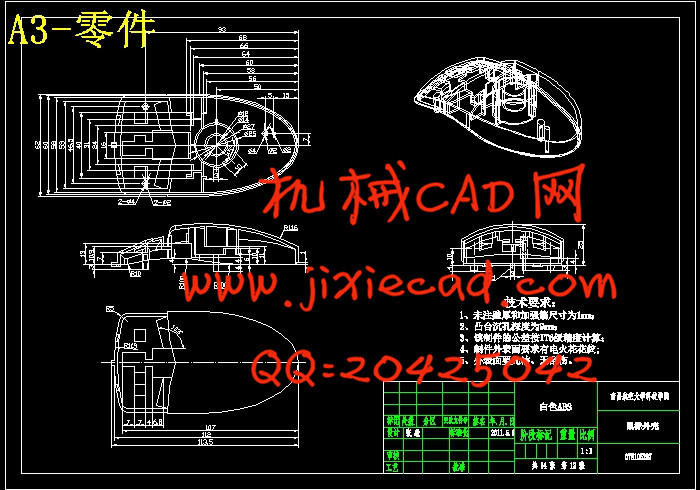

3 塑件分析 6

3.1 塑件的结构工艺性分析 6

3.2 计算塑件体积和容量及相关参数 9

4 材料的成型特性与工艺参数 9

5 设备的选择与校核 11

6 浇注系统的设计 14

6.1 塑料制件在模具中的位置 14

6.2 浇注系统的设计 15

6.3 排溢系统的设计 20

7 成型零部件的设计与计算 21

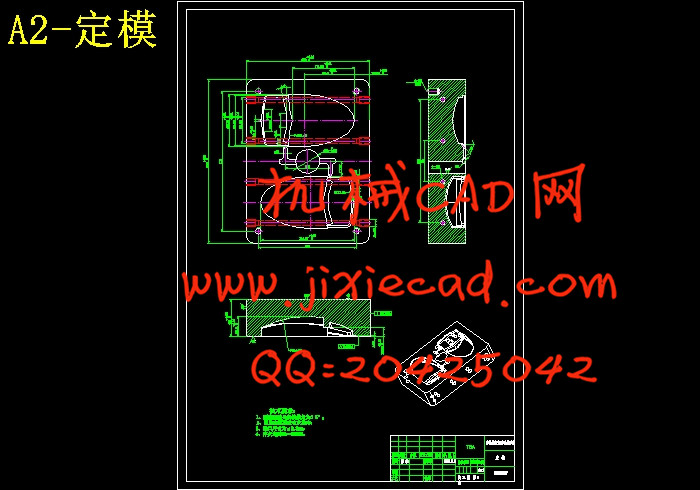

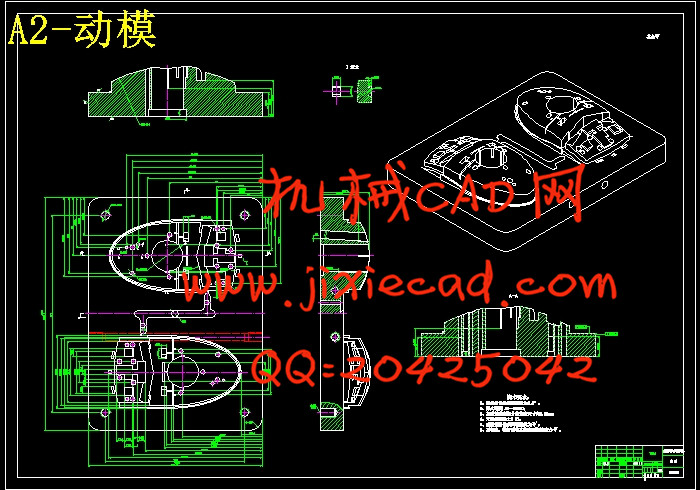

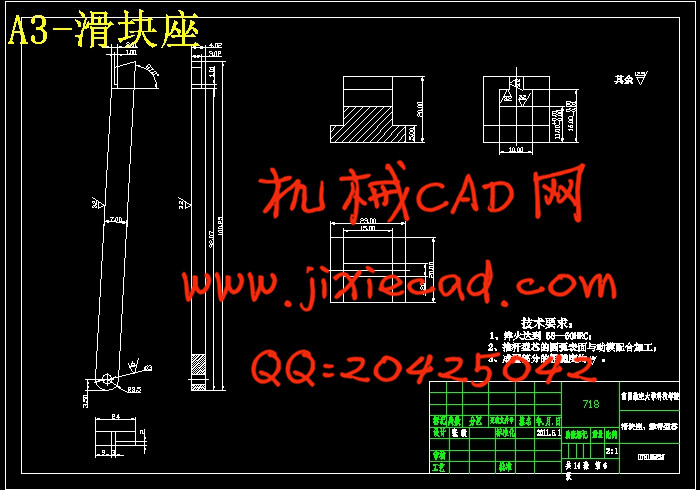

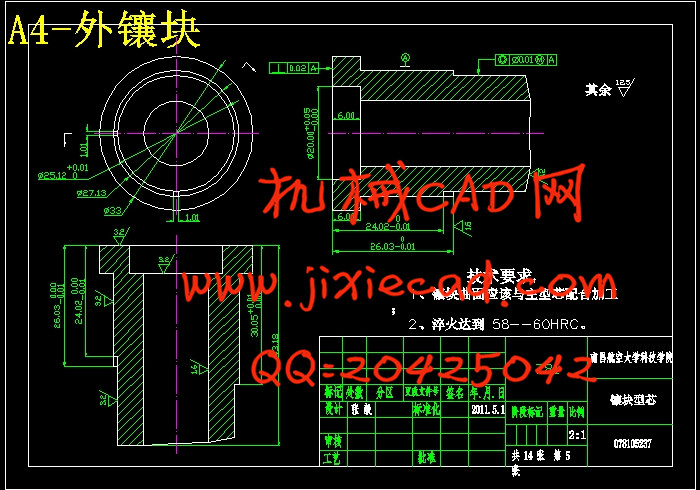

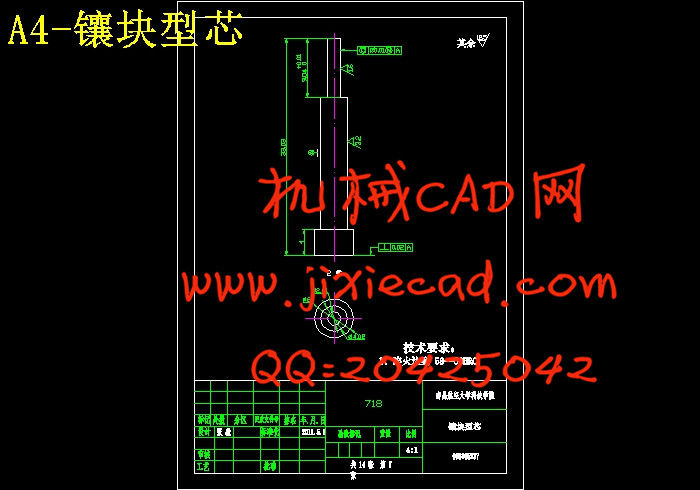

7.1 成型零件的结构设计 21

7.2 成型零件工作尺寸的计算 22

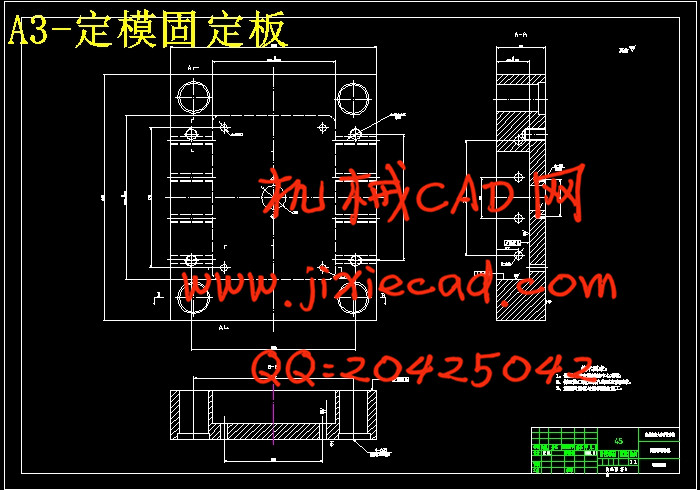

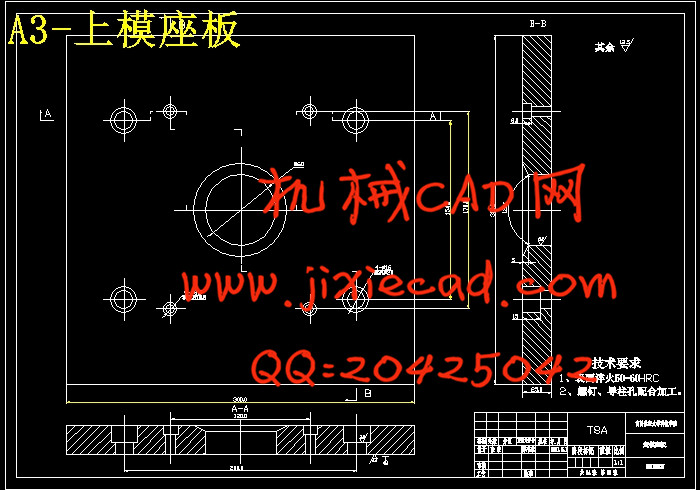

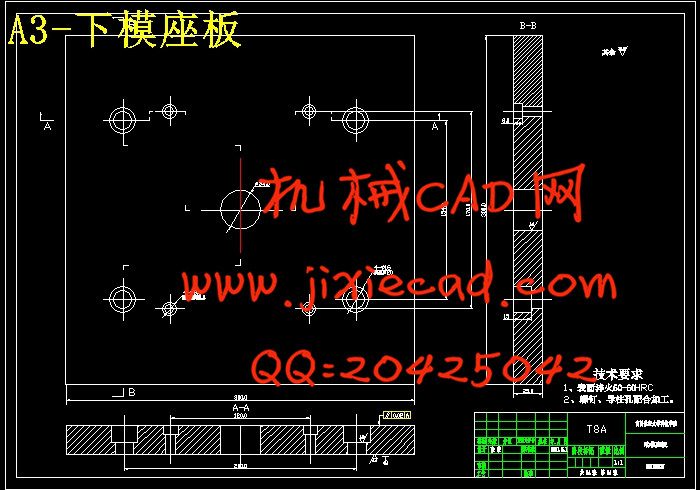

7.3 模架的选取 31

8 模机构的设计 31

8.1 脱模力的计算 32

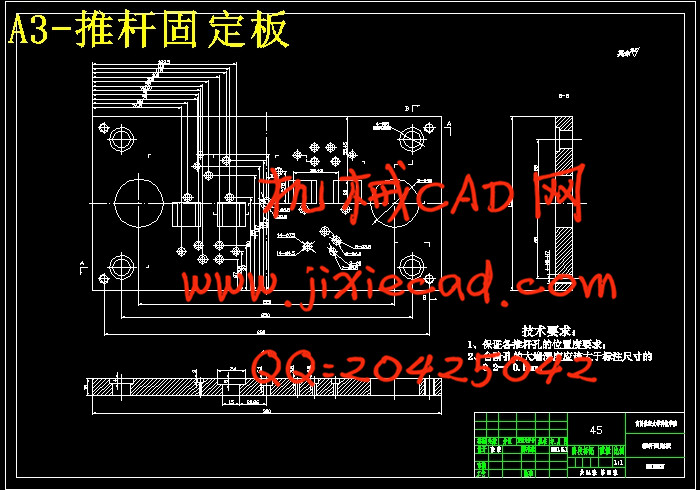

8.2 推出机构的设计 33

9 分型与抽芯机构的设计 35

10 合模导向机构设计 38

11 温度调节系统 42

12模具型面数控仿真加工 43

12.1 MasterCAM 9.0软件的简介 43

12.2 鼠标上盖注塑模的三维曲面造型 44

12.3鼠标上盖的三维曲面造型与数控仿真加工 53

结论 74

参考文献 76

致谢 77

在注塑产品开发中,模具的设计和制造决定塑料件的质量和成本。综观国内外先进制造技术的现状和发展,不难看出数字化制造技术是先进制造技术的核心技术。随着制造业的国际化,中国正逐渐成为制造业大国,

本文探讨了基于Mastercam平台实现注塑模具CAD/CAM的方法和途径,并以鼠标上盖为例,实现了注塑模具CAD/CAM过程。利用Mastercam软件提供CAM数控加工模块,完成了数控加工的全过程。本文详细介绍了注射模具浇注系统、温度调节系统和顶出系统的设计过程,鼠标上盖零件的结构及工艺性,确定该塑件的注塑成型方案并进行了注塑模设计方面的相关计算。CAD/CAM技术在模具行业中的应用,大大减少了模具设计制造的周期,取得了显著的经济效益,从根本上改变了传统的模具生产方式。

本文介绍了CAM技术在鼠标上盖注塑模具制造的NC加工中的应用过程,包括曲面建模、加工路径的选择、刀具轨迹计算等,并对该套模具NC加工编程的特殊性及其工艺处理作了分析。本文主要介绍了Mastercam模块的作用、加工能力和特点以及Mastercam加工类型和加工工艺简介,并用Mastercam实现仿真加工。

关键词:注塑模 CAD/CAM Mastercam

Abstract:Now the plastics industry is one of the growing quickest industry classes in the world, but the injection mold is develops the quick type. Therefore, There have biggist significance to research injection mold to understood that the plastic of production process and improve the product quality.A comprehensive survey of modern manufacturing technology indicated, that the digitized manufacturing is the key technique of advanced manufacturing technology.Our country is becoming a big factory.

Based on Mastercam,the author present the method for Mastercam to achieve mould CAD/CAM, and take the mouse-up as an example, describe the process of UG mould CAD/C AM in detail.The authors complete the NC manufacturing of mold’s core in Mastercam software.This design introduced the cold flow channel injection evil spirit mold pours the system, the temperature control system and goes against the system the design process, the analyzing of the structure and crafts of the mouse-up shells, deciding the way of the injecting and doing certain calculation relating to the injecting-mold. The using of CAD/CAM technology in mold industry decreases the time of mold-making with the result of increasing economies efficiency and ultimately exchanging the mode of traditional model-making.

The application procedure of CAM in the mouse-up injection mold NC manufacturing is introduced in the paper.The procedure includes surface modeling, manufacture path selection, tool path calculating.An analyses of the characteristic of NC program and the dispose of technics about the mouse-up-mold is made. The article mainly introduce the friction、capacity and term of Mastercam and manufacturing types and technics of Mastercam, has stress on the integration of the core of the mouse-up-mould,and realize its emulation.

Key word:Injection Mould CAD/CAM Mastercam

引言 1

1 绪论 2

1.1 我国模具企业技术现状及发展趋势 2

2.1 本次毕业设计应达到的目的 5

2 设计任务书 5

3 塑件分析 6

3.1 塑件的结构工艺性分析 6

3.2 计算塑件体积和容量及相关参数 9

4 材料的成型特性与工艺参数 9

5 设备的选择与校核 11

6 浇注系统的设计 14

6.1 塑料制件在模具中的位置 14

6.2 浇注系统的设计 15

6.3 排溢系统的设计 20

7 成型零部件的设计与计算 21

7.1 成型零件的结构设计 21

7.2 成型零件工作尺寸的计算 22

7.3 模架的选取 31

8 模机构的设计 31

8.1 脱模力的计算 32

8.2 推出机构的设计 33

9 分型与抽芯机构的设计 35

10 合模导向机构设计 38

11 温度调节系统 42

12模具型面数控仿真加工 43

12.1 MasterCAM 9.0软件的简介 43

12.2 鼠标上盖注塑模的三维曲面造型 44

12.3鼠标上盖的三维曲面造型与数控仿真加工 53

结论 74

参考文献 76

致谢 77