设计简介

摘 要

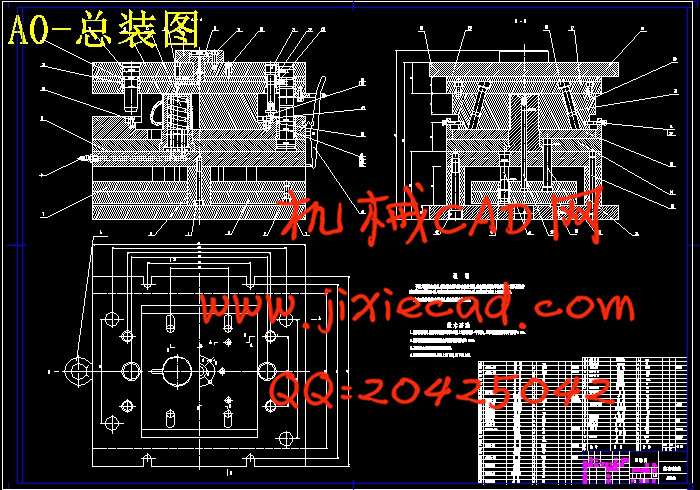

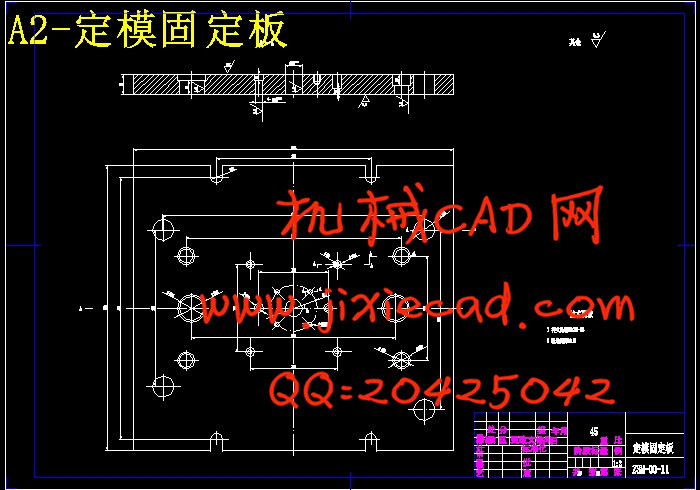

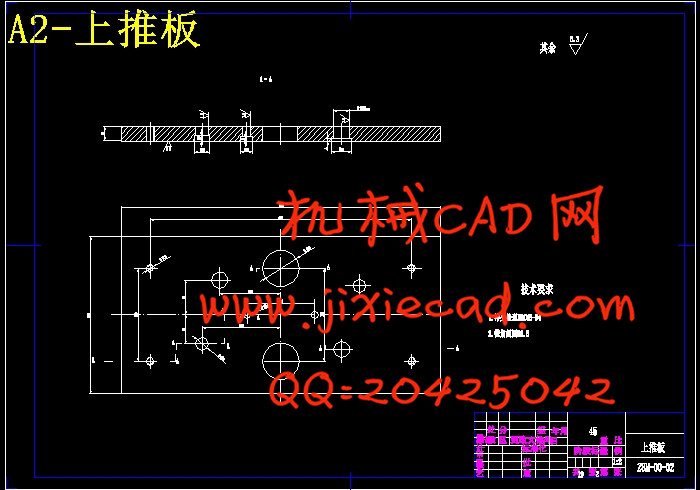

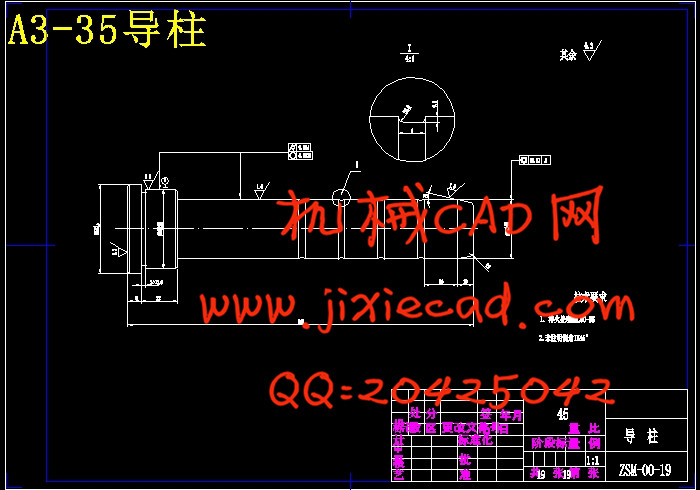

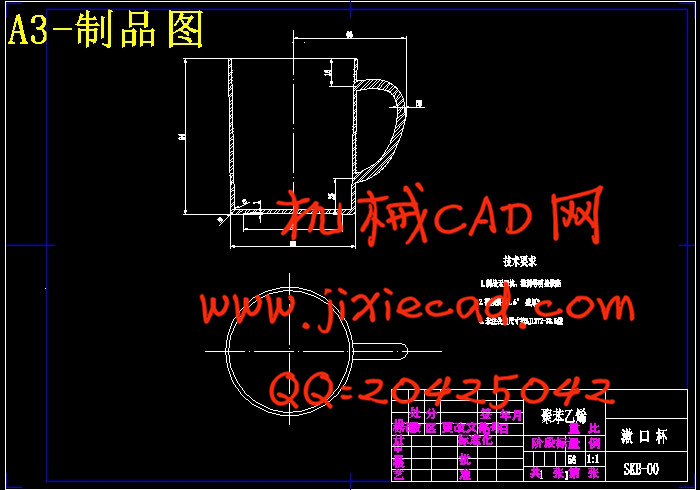

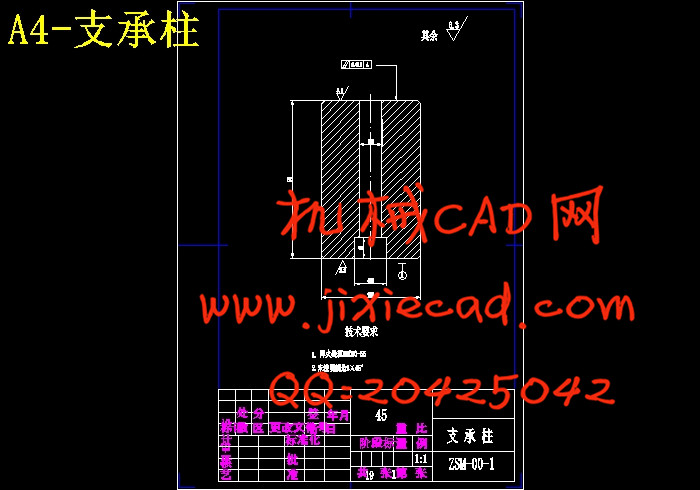

本文主要介绍了漱口杯注塑模设计,塑料成形工艺以及注塑的过程,也对注塑机也进行了一些简单的介绍。注塑模设计的主要过程有:塑料制品的工艺分析,型腔数目的确定,注塑机的选择以及模具的结构设计。模具的结构设计包括:浇注系统的设计,成型零件设计,导向机构设计,侧面分型机构设计,脱模机构设计,冷却机构设计以及排气系统设计。本文设计的是一模两腔三板式模具。由于漱口杯的特殊形状,无法直接脱模,需设置侧面分型机构,本套模具是通过斜导柱进行侧面分型,本文对模具的各部分零件进行了设计与计算。本文对模具的工作原理和工作过程,以及模具的使用与保养也进行了说明。本文给出了详细的设计过程及装配图。

关键词 漱口杯 注塑模 设计 侧分型

Abstract

the text introduced that how to design the note moulding of tooth glass,the craft of taking shape of the plastics,the process of moulding plastics .and also introduced the mould machine. The note moulds the main course designed to have: Analyse , the sureness of one of figures of the type, the structure of the choice and mould of the moulding plastics machine is designed in craft of the plastic products. The structure of the mould is designed and includes: Pouring the systematic design, the shaping part is designed, lead the organization to design, The side designs in dividing type organization, organization designs, cool the mechanism and is designed and exhausts to the system and designed the drawing of patterns. the text designed a three modes two type mould machine. Through the oblioque lead post the mould machine was inclined the dividing type .all part of part in mould designed and calculates, And the design and laying position etc. introduced the principle and process of operation. And the maintenance and maintaining some requests of proposition to the mould .

Keywords: tooth glass the note molding design incline the dividing type

目 录

0绪论…………………………………………………………………………………… 1

1塑料制品的工艺分析………………………………………………………………… 4

1.1 塑料制品的工艺分析…………………………………………………………… 4

1.2注塑过程的特点…………………………………………………………………… 6

2 确定型腔数目……………………………………………………………………… 7

3 注塑机的选择………………………………………………………………………… 8

4浇注系统的设计……………………………………………………………………… 11

4.1 设计浇注系统基本要点…………………………………………………………… 11

4.2 主流道设计………………………………………………………………………… 11

4.3 分流道设计………………………………………………………………………… 12

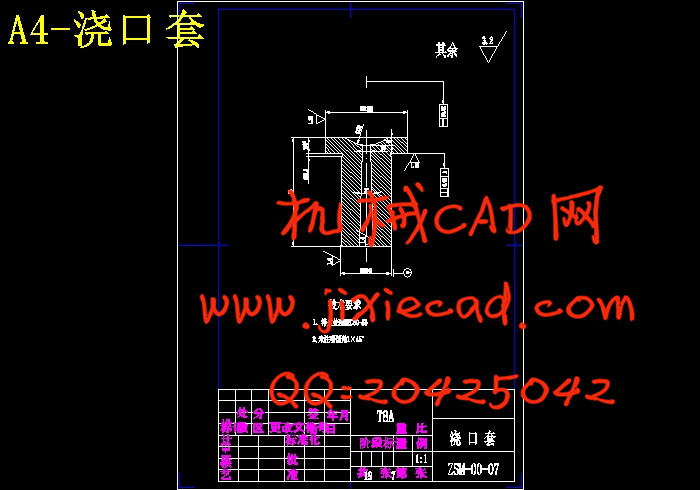

4.4 浇口设计…………………………………………………………………………… 13

4.5 冷料穴设计………………………………………………………………………… 14

4.6 排气槽设计………………………………………………………………………… 14

5 成型零件结构设计………………………………………………………………… 15

5.1分型面确定………………………………………………………………………… 15

5.2成型零件的结构形式及设计……………………………………………………… 15

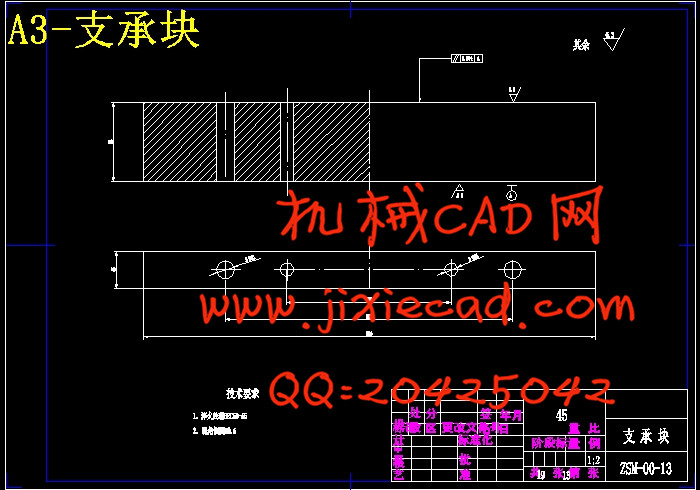

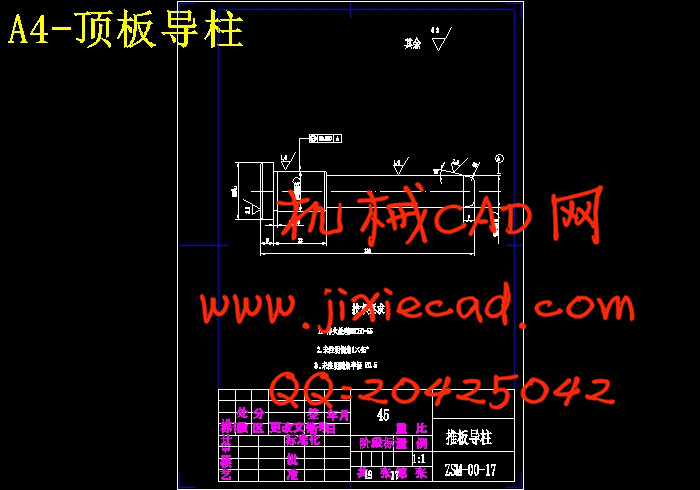

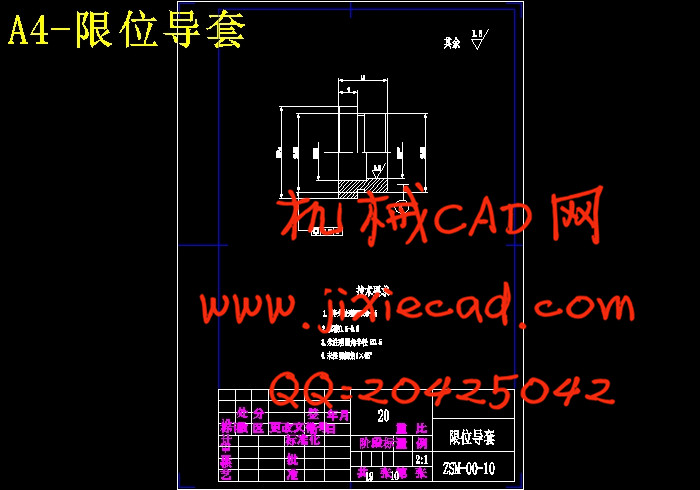

6导向机构设计………………………………………………………………………… 18

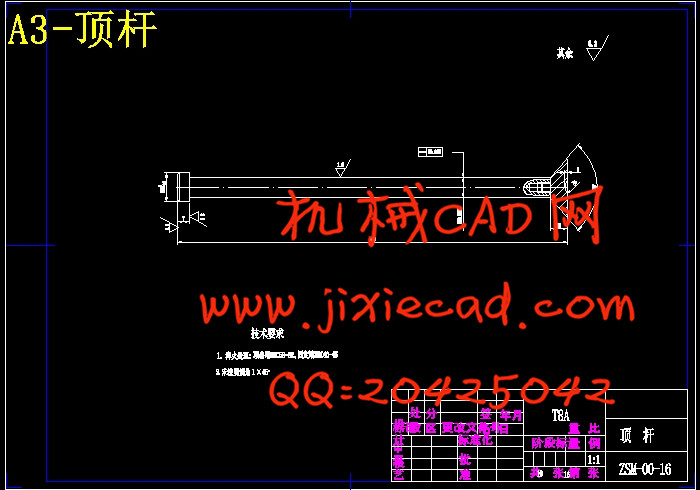

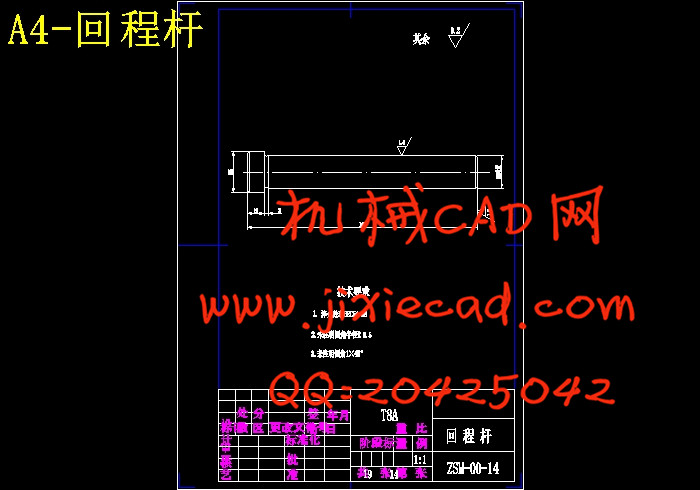

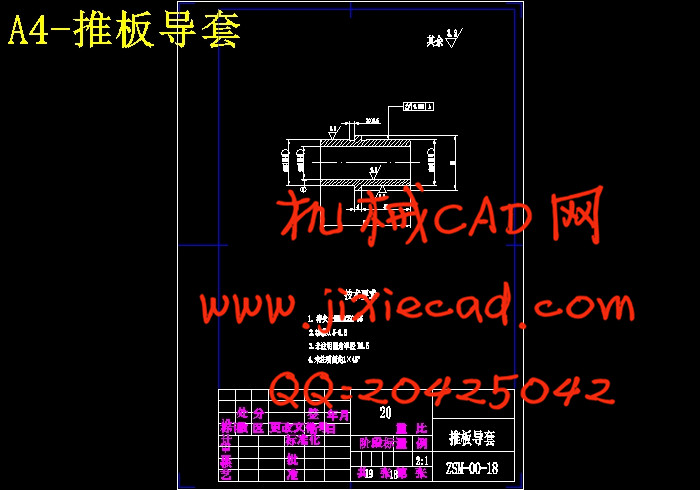

7 脱模机构设计……………………………………………………………………… 19

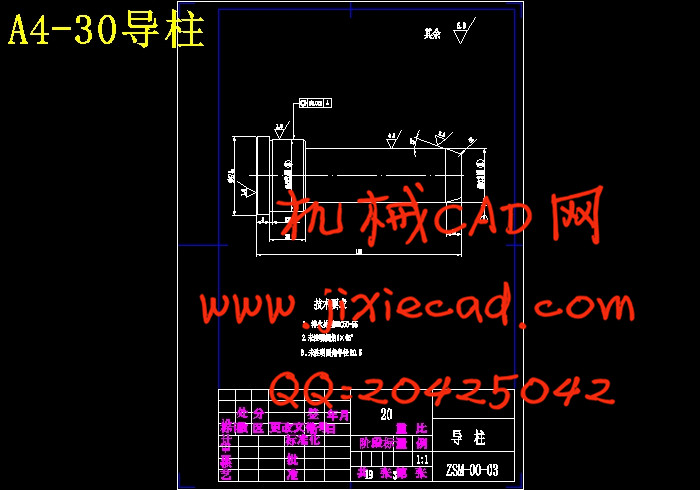

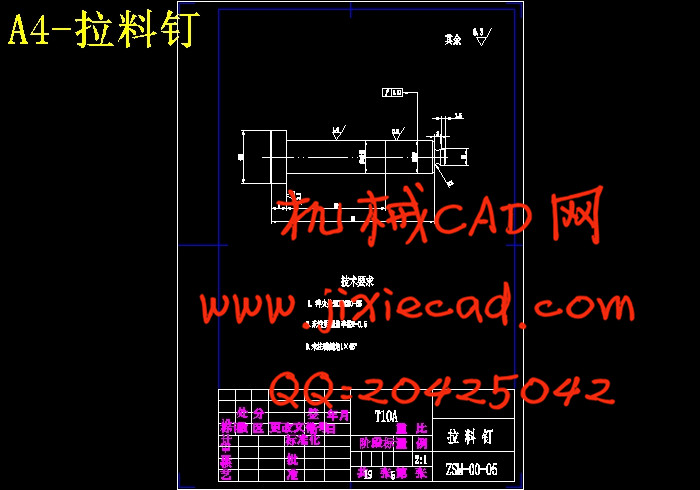

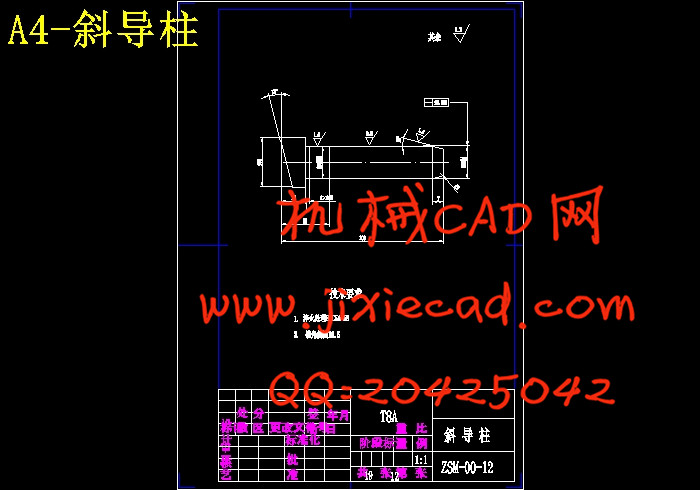

8 侧面分型机构设计…………………………………………………………………… 20

8.1概述………………………………………………………………………………… 20

8.2 斜导柱侧分型机构设计…………………………………………………………… 20

9 冷却系统的设计……………………………………………………………………… 22

10 模板厚度的确定………………………………………………………………………23

11 模具用钢………………………………………………………………………………24

12 模具的使用与保养……………………………………………………………………25

小结……………………………………………………………………………………… 26

参考文献………………………………………………………………………………… 27

附件清单………………………………………………………………………………… 28

本文主要介绍了漱口杯注塑模设计,塑料成形工艺以及注塑的过程,也对注塑机也进行了一些简单的介绍。注塑模设计的主要过程有:塑料制品的工艺分析,型腔数目的确定,注塑机的选择以及模具的结构设计。模具的结构设计包括:浇注系统的设计,成型零件设计,导向机构设计,侧面分型机构设计,脱模机构设计,冷却机构设计以及排气系统设计。本文设计的是一模两腔三板式模具。由于漱口杯的特殊形状,无法直接脱模,需设置侧面分型机构,本套模具是通过斜导柱进行侧面分型,本文对模具的各部分零件进行了设计与计算。本文对模具的工作原理和工作过程,以及模具的使用与保养也进行了说明。本文给出了详细的设计过程及装配图。

关键词 漱口杯 注塑模 设计 侧分型

Abstract

the text introduced that how to design the note moulding of tooth glass,the craft of taking shape of the plastics,the process of moulding plastics .and also introduced the mould machine. The note moulds the main course designed to have: Analyse , the sureness of one of figures of the type, the structure of the choice and mould of the moulding plastics machine is designed in craft of the plastic products. The structure of the mould is designed and includes: Pouring the systematic design, the shaping part is designed, lead the organization to design, The side designs in dividing type organization, organization designs, cool the mechanism and is designed and exhausts to the system and designed the drawing of patterns. the text designed a three modes two type mould machine. Through the oblioque lead post the mould machine was inclined the dividing type .all part of part in mould designed and calculates, And the design and laying position etc. introduced the principle and process of operation. And the maintenance and maintaining some requests of proposition to the mould .

Keywords: tooth glass the note molding design incline the dividing type

目 录

0绪论…………………………………………………………………………………… 1

1塑料制品的工艺分析………………………………………………………………… 4

1.1 塑料制品的工艺分析…………………………………………………………… 4

1.2注塑过程的特点…………………………………………………………………… 6

2 确定型腔数目……………………………………………………………………… 7

3 注塑机的选择………………………………………………………………………… 8

4浇注系统的设计……………………………………………………………………… 11

4.1 设计浇注系统基本要点…………………………………………………………… 11

4.2 主流道设计………………………………………………………………………… 11

4.3 分流道设计………………………………………………………………………… 12

4.4 浇口设计…………………………………………………………………………… 13

4.5 冷料穴设计………………………………………………………………………… 14

4.6 排气槽设计………………………………………………………………………… 14

5 成型零件结构设计………………………………………………………………… 15

5.1分型面确定………………………………………………………………………… 15

5.2成型零件的结构形式及设计……………………………………………………… 15

6导向机构设计………………………………………………………………………… 18

7 脱模机构设计……………………………………………………………………… 19

8 侧面分型机构设计…………………………………………………………………… 20

8.1概述………………………………………………………………………………… 20

8.2 斜导柱侧分型机构设计…………………………………………………………… 20

9 冷却系统的设计……………………………………………………………………… 22

10 模板厚度的确定………………………………………………………………………23

11 模具用钢………………………………………………………………………………24

12 模具的使用与保养……………………………………………………………………25

小结……………………………………………………………………………………… 26

参考文献………………………………………………………………………………… 27

附件清单………………………………………………………………………………… 28