设计简介

摘 要

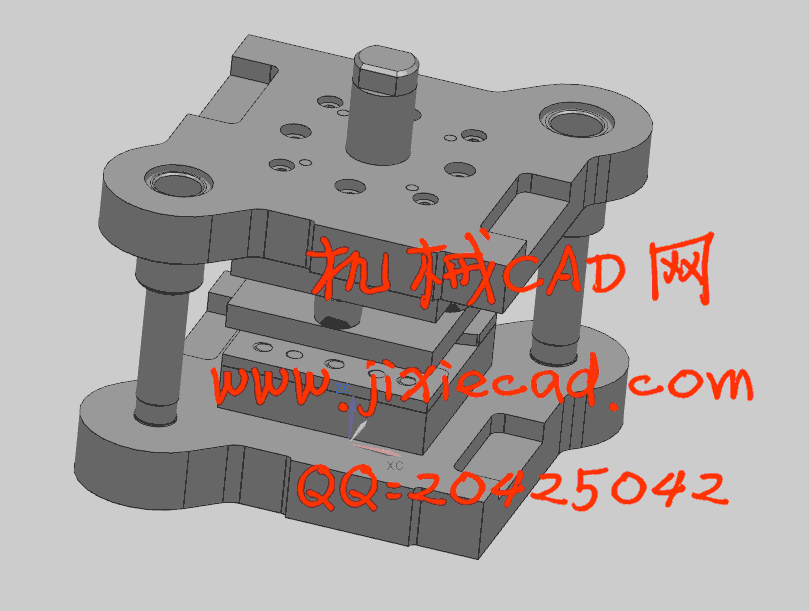

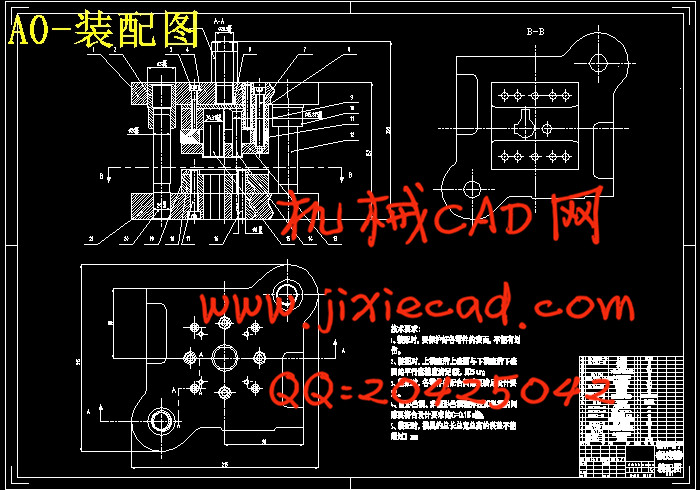

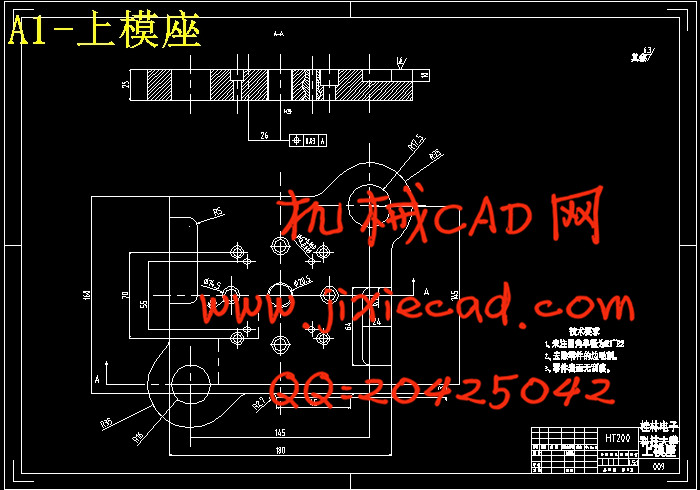

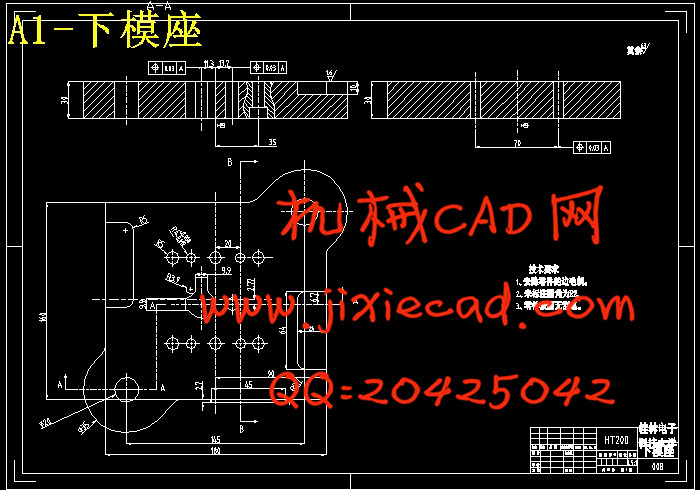

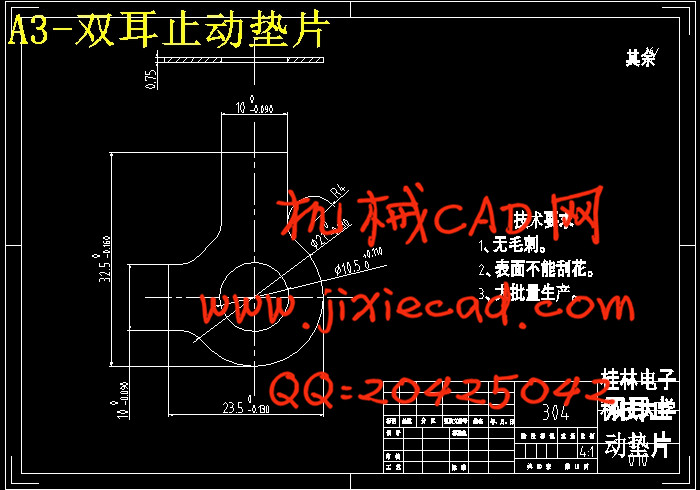

随着社会生产力的提高与发展,现如今模具制造中的冲压加工已经是一种非常成熟的金属加工方法。它具有操作简单、精度高、产品一致性好、生产效率高、材料利用率高和用于大批量生产等特点。本次毕业设计根据已经确定的冲载件即双耳止动垫片的尺寸进行冲载工艺的分析及设计,从而得到冲载工艺。根据已经确定好的冲载工艺进行凸凹模结构参数的计算与设计,并根据文献资料最终确定级进模的凸凹模结构。根据设计好的凸凹模结构选择标准零件和模架,从而完成模具的设计并校核。完成模具设计后,用UG软件完成模具的三维模型并采用AutoCAD软件完成模具装配图的制图。本次毕业设计还独立完成与专业相关且不少于4万字符的指定英文资料翻译。通过本次毕业设计,我系统的学习和掌握了模具设计的知识和制造加工工艺的编制技术。我采用了较好的设计思想和设计方法,成功的完成了双耳止动垫片冲孔落料级进模的毕业设计。

关键词:设计;工艺分析;冲压模具;结构计算;级进模。

Abstract

With the improvement and development of social productive forces, the stamping of Mold Manufacturing now is already a very advanced metal processing methods. It has the feature of simple operation, high accuracy, product consistency, high production efficiency, high utilization of materials and for mass production and so on. The graduation project bases on the pieces(binaural washer)of punch set that have been identified in binaural washer dimensions for analysis and design of the craft of punch set resulting in getting the craft of punch. I will do the job of calculation and design of structural parameters punch basing on the craft of punch set that has been determined,and ultimately determine the progressive of punch structure of Progressive Die according to the literature. I select the standard parts and the mold according to the designed structure of punch structure .Thus completing the mold design. After the completion of mold design, I use UG software to complete three-dimensional model and use AutoCAD software to complete the graphics of mold assembly drawing. The graduation project is independently complete not less than40,000 characters of the specified English translation associated with professional. Through this graduation design, I learn systematically and mastered the preparation of technical of manufacturing process and knowledge of mold design. I used the advanced design concepts and design methods, and I successfully complete the graduate design of Binaural Washer Punching and Blanking Progressive Die Design.

Key words : design; process analysis; stamping die; progressive die; structural calculations.

目 录

引言 1

1 冲载件的工艺性分析 2

1.1 冲载件 2

1.1.1冲载件材料的选择 2

1.1.2冲载件结构分析 2

1.1.3冲载件尺寸精度 2

1.2 冲载模的选择 3

1.2.1方案一 — 单工序模生产 3

1.2.3方案二 — 复合模生产 3

1.2.3方案三 — 级进模生产 3

2 冲载工艺设计 4

2.1 排样方式的确定及计算 4

2.1.1搭边值的确定 4

2.1.2确定排料方向 4

2.1.3计算送料步距A 5

2.1.4计算料条宽度B 5

2.1.5排样图 5

2.1.6计算材料的利用率 6

2.2 级进模压力中心的建立 7

2.3 冲载力的计算 9

2.3.1 冲孔力 10

2.3.2 落料力 10

2.3.3 冲载力 10

2.3.4 卸料力、推件力和顶件力 10

2.3.5 压力机的选择 11

3级进模设计 12

3.1 凸、凹刃口尺寸计算 12

3.1.1 冲孔时凸、凹模刃口尺寸的计算 12

3.1.2对于落料时凸、凹模刃口尺寸的计算 12

3.2 凸、凹模外形尺寸计算及确定 14

3.2.1冲孔及落料凸模外形尺寸计算及确定 14

3.2.1冲孔及落料凸模外形尺寸计算及确定 16

4 级进模主要零件设计 17

4.1 级进模模架的设计 17

4.2级进模模柄的设计 18

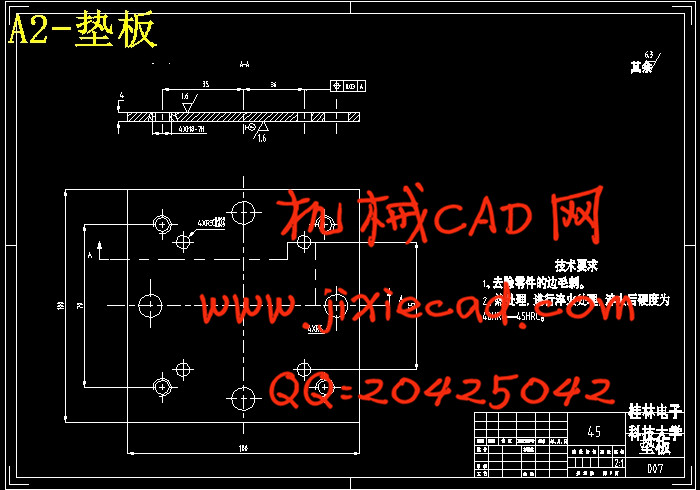

4.3 级进模垫板的设计 19

4.4 凸模固定板的设计 20

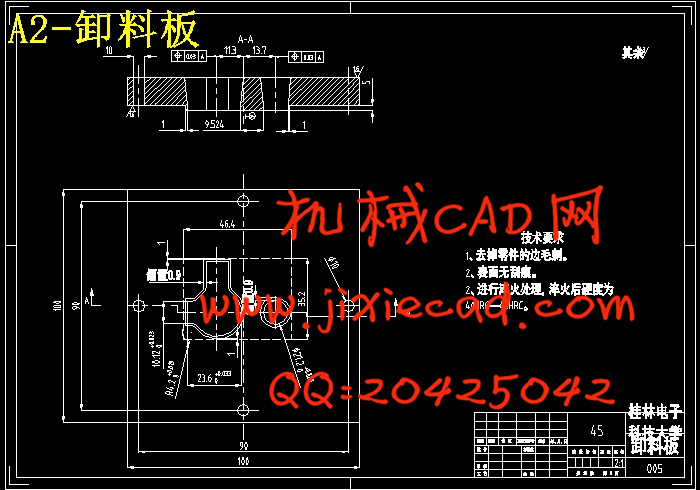

4.5 弹性卸料板设计 21

4.6 导料板的设计 23

4.7 标准圆柱销和内六角圆柱螺钉的选择 23

4.8 级进模导柱和导套的选择 25

4.9 级进模校核 26

5 级进模零件材料的选择 27

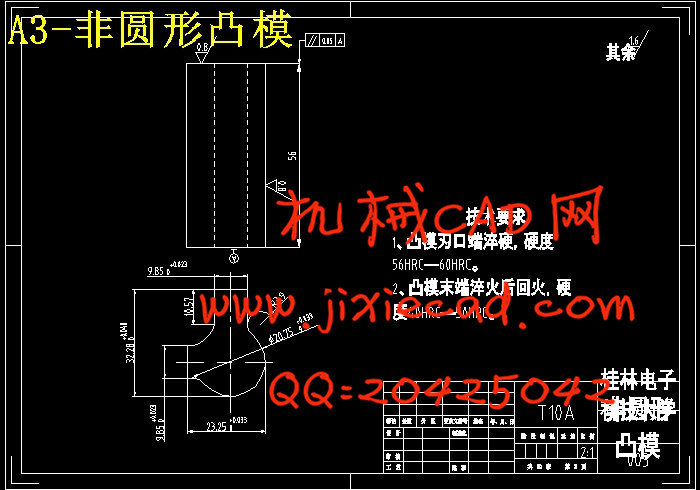

5.1 级进模凸模选材 27

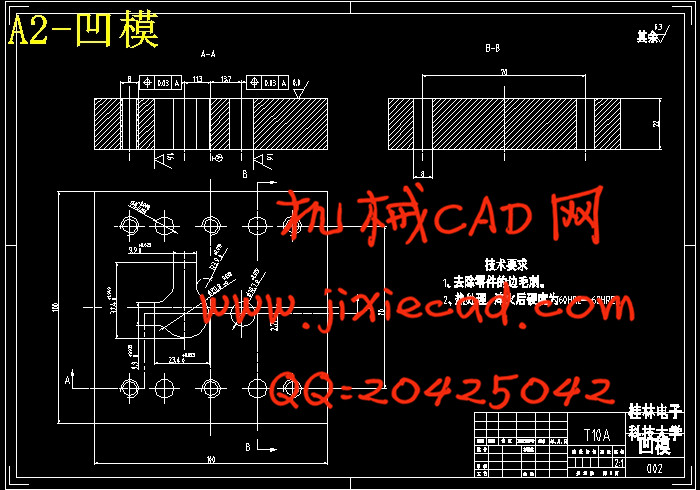

5.2 级进模凹模选材 28

5.3 级进模上、下模座选材 28

5.4 级进模导柱和导套选材 28

5.5 级进模其他零件的选材 29

5.5.1级进模垫板、导料板和卸料板选材 29

5.5.2 级进模凸模固定板选材 29

6 级进模主要零部件的加工工艺 30

6.1 凸模加工工艺 30

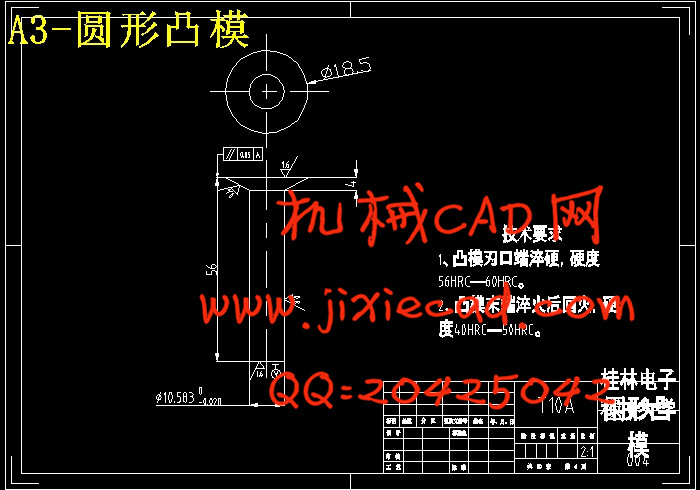

6.1.1圆形凸模加工工艺 30

6.1.2非圆形凸模加工工艺 30

7 级进模的UG建模和autoCAD制图 31

总结 33

谢 辞 34

参考文献 35

随着社会生产力的提高与发展,现如今模具制造中的冲压加工已经是一种非常成熟的金属加工方法。它具有操作简单、精度高、产品一致性好、生产效率高、材料利用率高和用于大批量生产等特点。本次毕业设计根据已经确定的冲载件即双耳止动垫片的尺寸进行冲载工艺的分析及设计,从而得到冲载工艺。根据已经确定好的冲载工艺进行凸凹模结构参数的计算与设计,并根据文献资料最终确定级进模的凸凹模结构。根据设计好的凸凹模结构选择标准零件和模架,从而完成模具的设计并校核。完成模具设计后,用UG软件完成模具的三维模型并采用AutoCAD软件完成模具装配图的制图。本次毕业设计还独立完成与专业相关且不少于4万字符的指定英文资料翻译。通过本次毕业设计,我系统的学习和掌握了模具设计的知识和制造加工工艺的编制技术。我采用了较好的设计思想和设计方法,成功的完成了双耳止动垫片冲孔落料级进模的毕业设计。

关键词:设计;工艺分析;冲压模具;结构计算;级进模。

Abstract

With the improvement and development of social productive forces, the stamping of Mold Manufacturing now is already a very advanced metal processing methods. It has the feature of simple operation, high accuracy, product consistency, high production efficiency, high utilization of materials and for mass production and so on. The graduation project bases on the pieces(binaural washer)of punch set that have been identified in binaural washer dimensions for analysis and design of the craft of punch set resulting in getting the craft of punch. I will do the job of calculation and design of structural parameters punch basing on the craft of punch set that has been determined,and ultimately determine the progressive of punch structure of Progressive Die according to the literature. I select the standard parts and the mold according to the designed structure of punch structure .Thus completing the mold design. After the completion of mold design, I use UG software to complete three-dimensional model and use AutoCAD software to complete the graphics of mold assembly drawing. The graduation project is independently complete not less than40,000 characters of the specified English translation associated with professional. Through this graduation design, I learn systematically and mastered the preparation of technical of manufacturing process and knowledge of mold design. I used the advanced design concepts and design methods, and I successfully complete the graduate design of Binaural Washer Punching and Blanking Progressive Die Design.

Key words : design; process analysis; stamping die; progressive die; structural calculations.

目 录

引言 1

1 冲载件的工艺性分析 2

1.1 冲载件 2

1.1.1冲载件材料的选择 2

1.1.2冲载件结构分析 2

1.1.3冲载件尺寸精度 2

1.2 冲载模的选择 3

1.2.1方案一 — 单工序模生产 3

1.2.3方案二 — 复合模生产 3

1.2.3方案三 — 级进模生产 3

2 冲载工艺设计 4

2.1 排样方式的确定及计算 4

2.1.1搭边值的确定 4

2.1.2确定排料方向 4

2.1.3计算送料步距A 5

2.1.4计算料条宽度B 5

2.1.5排样图 5

2.1.6计算材料的利用率 6

2.2 级进模压力中心的建立 7

2.3 冲载力的计算 9

2.3.1 冲孔力 10

2.3.2 落料力 10

2.3.3 冲载力 10

2.3.4 卸料力、推件力和顶件力 10

2.3.5 压力机的选择 11

3级进模设计 12

3.1 凸、凹刃口尺寸计算 12

3.1.1 冲孔时凸、凹模刃口尺寸的计算 12

3.1.2对于落料时凸、凹模刃口尺寸的计算 12

3.2 凸、凹模外形尺寸计算及确定 14

3.2.1冲孔及落料凸模外形尺寸计算及确定 14

3.2.1冲孔及落料凸模外形尺寸计算及确定 16

4 级进模主要零件设计 17

4.1 级进模模架的设计 17

4.2级进模模柄的设计 18

4.3 级进模垫板的设计 19

4.4 凸模固定板的设计 20

4.5 弹性卸料板设计 21

4.6 导料板的设计 23

4.7 标准圆柱销和内六角圆柱螺钉的选择 23

4.8 级进模导柱和导套的选择 25

4.9 级进模校核 26

5 级进模零件材料的选择 27

5.1 级进模凸模选材 27

5.2 级进模凹模选材 28

5.3 级进模上、下模座选材 28

5.4 级进模导柱和导套选材 28

5.5 级进模其他零件的选材 29

5.5.1级进模垫板、导料板和卸料板选材 29

5.5.2 级进模凸模固定板选材 29

6 级进模主要零部件的加工工艺 30

6.1 凸模加工工艺 30

6.1.1圆形凸模加工工艺 30

6.1.2非圆形凸模加工工艺 30

7 级进模的UG建模和autoCAD制图 31

总结 33

谢 辞 34

参考文献 35