设计简介

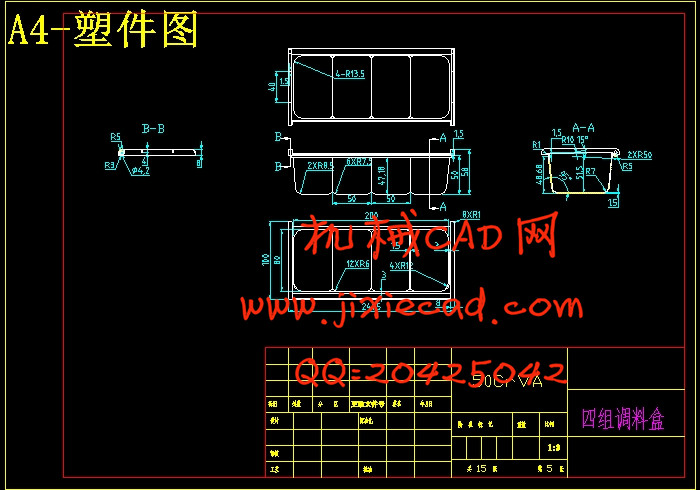

摘 要:本模具设计的课题是四组调料盒,针对调料盒进行了相关的工艺设计和模具设计。设计中利用CAD与PROE等软件对模具进行计算分析,提高了模具设计合理性。本模具在节约模具成本、缩短生产周期、提高模具寿命取得了较大的成就。

关键词:注塑模; 调料盒; 合理性

Abstract:This mold design's topic is four group of seasoning boxes, according to the related seasoning box,I did the associated process design and die design. In this design,I used CAD software and the PROE to do calculation and analysis for mold, to improve the mold design's rationality. The mold have made great achievements in saving mould cost, shorten the production cycle and improve die’s life.

Key words:injection mold; seasoning box; rationality

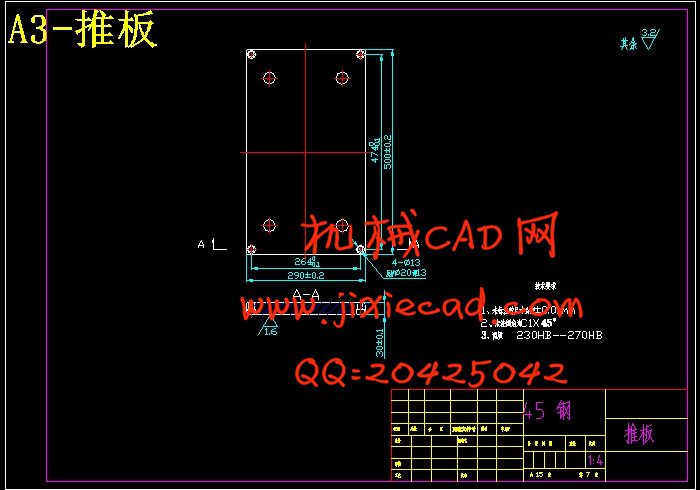

目 录

摘要…………………………………………………………………^………………………1

关键词………………………………………………………………………………………1

1 前言………………………………………………………………………………………1

2 塑件材料性能……………………………………………………………………………2

2.1 ABS材料分析………………………………………………………………………2

2.2 塑料成型工艺性能分析…………………………………………………………2

3 塑料件的结构工艺………………………………………………………………………4

3.1 塑料件的尺寸精度分析…………………………………………………………4

3.2 塑料件的使用性能分析…………………………………………………………4

3.3 塑料件的表面质量分析…………………………………………………………4

3.4 塑料件的结构分析………………………………………………………………4

4 成型设备的选择和成型工艺的制定……………………………………………………5

4.1 成型参数的确定…………………………………………………………………5

4.2 塑件的体积和重量的计算………………………………………………………6

4.3 模具所需塑料熔体注射量………………………………………………………6

4.4 锁模力的计算……………………………………………………………………6

4.5 设备选择…………………………………………………………………………7

4.6 塑料成型工艺卡…………………………………………………………………8

5 注射模设计……………………………………………………………………………8

5.1 可行性分析………………………………………………………………………8

5.2 确定模具的类型…………………………………………………………………10

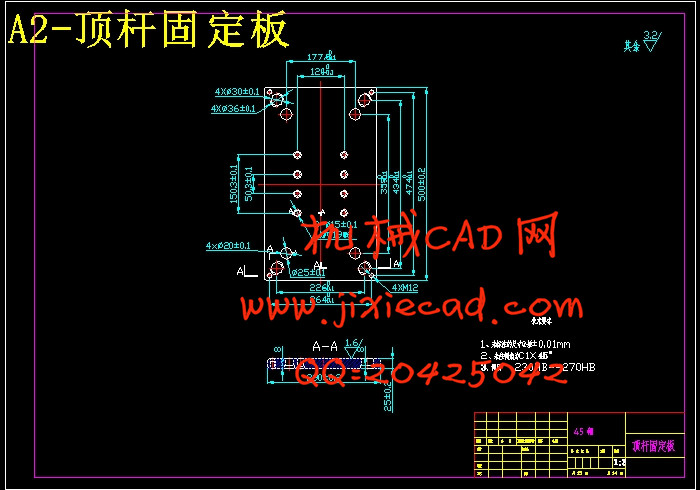

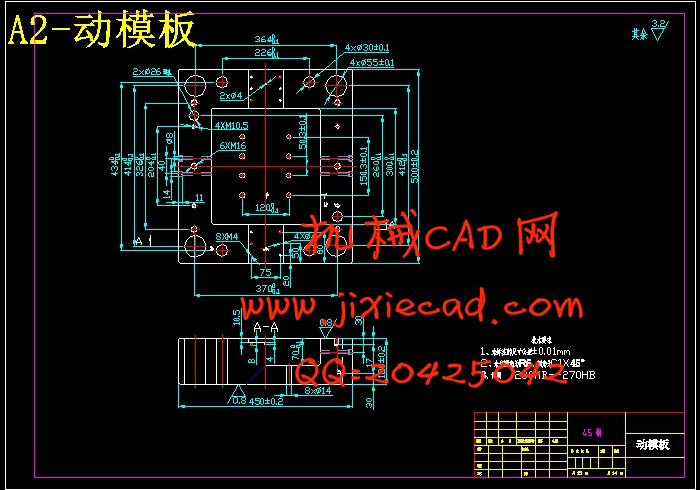

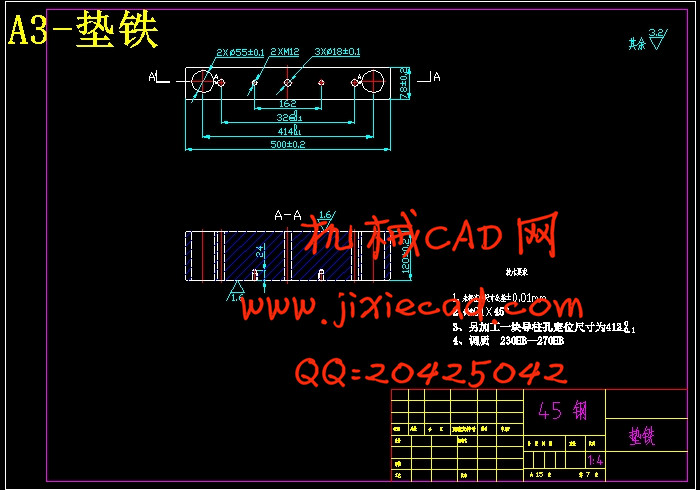

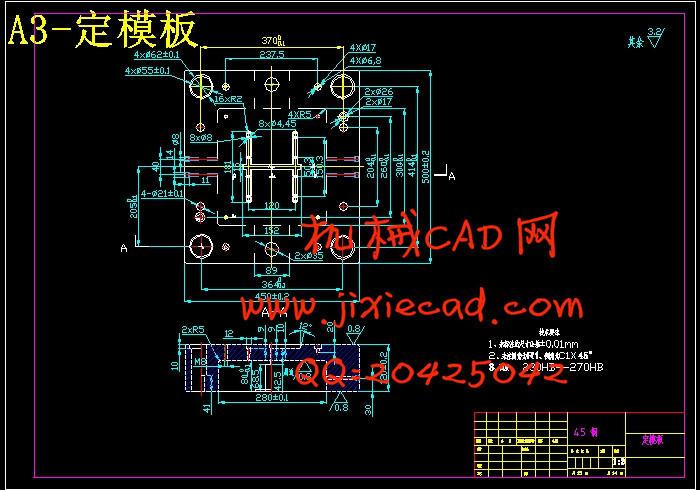

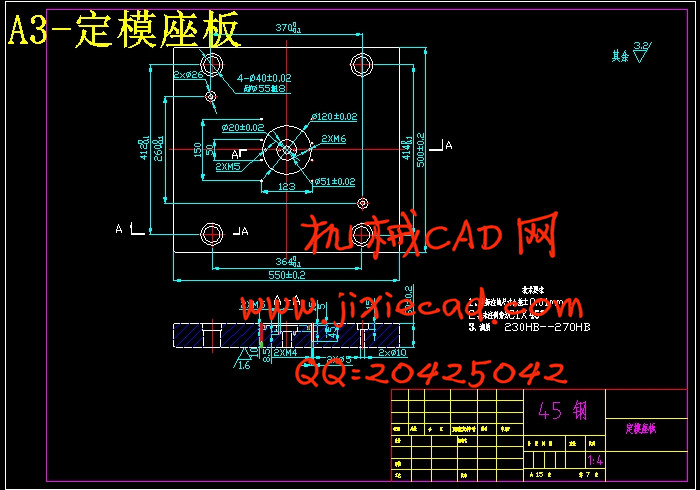

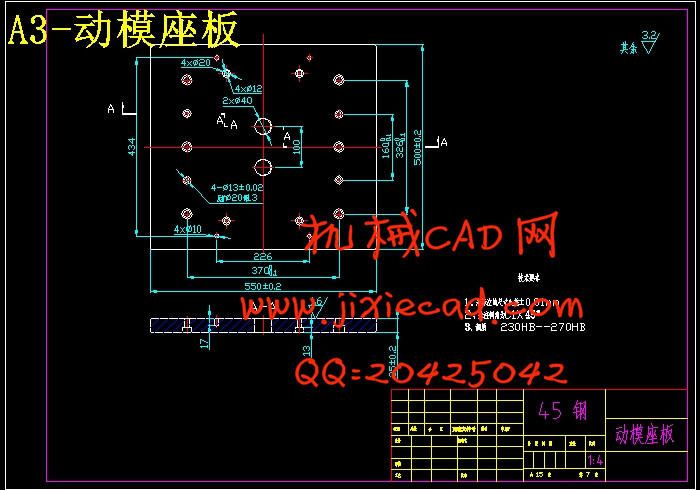

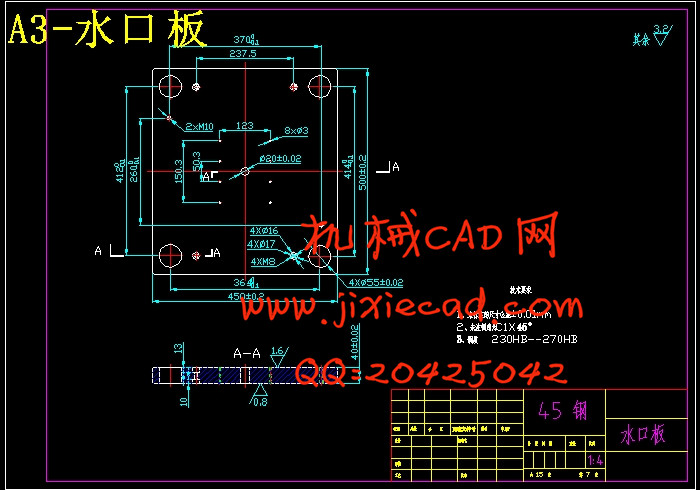

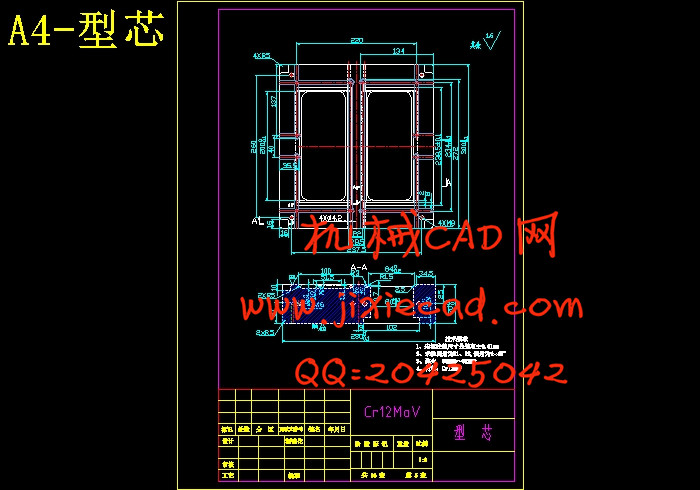

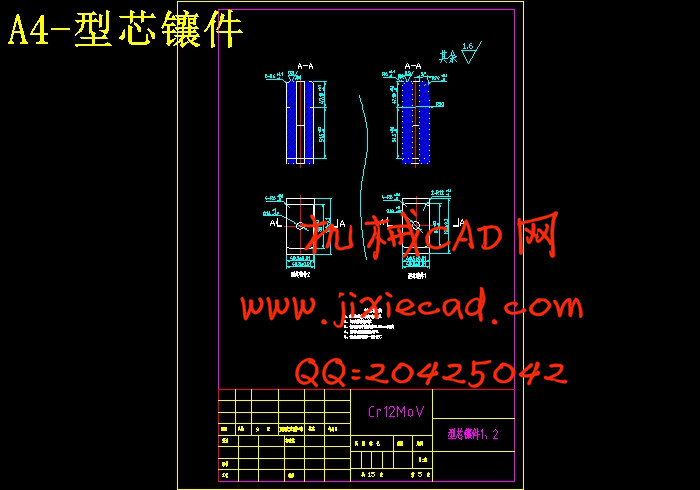

5.3 确定模具的主要结构……………………………………………………………10

6 安装与试模……………………………………………………………………………30

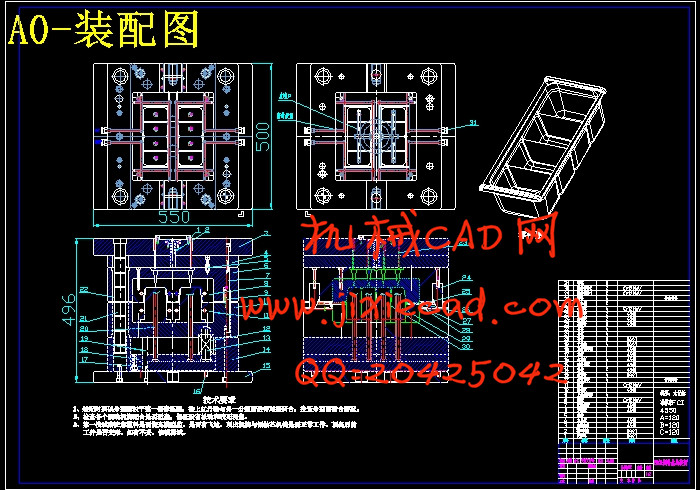

6.1 模具的安装结构图………………………………………………………………30

6.2 模具工作过程……………………………………………………………………31

6.3 模具的安装试模…………………………………………………………………32

结论…………………………………………………………………………………………33

参考文献 …………………………………………………………………………………33

致谢…………………………………………………………………………………………34

关键词:注塑模; 调料盒; 合理性

Abstract:This mold design's topic is four group of seasoning boxes, according to the related seasoning box,I did the associated process design and die design. In this design,I used CAD software and the PROE to do calculation and analysis for mold, to improve the mold design's rationality. The mold have made great achievements in saving mould cost, shorten the production cycle and improve die’s life.

Key words:injection mold; seasoning box; rationality

目 录

摘要…………………………………………………………………^………………………1

关键词………………………………………………………………………………………1

1 前言………………………………………………………………………………………1

2 塑件材料性能……………………………………………………………………………2

2.1 ABS材料分析………………………………………………………………………2

2.2 塑料成型工艺性能分析…………………………………………………………2

3 塑料件的结构工艺………………………………………………………………………4

3.1 塑料件的尺寸精度分析…………………………………………………………4

3.2 塑料件的使用性能分析…………………………………………………………4

3.3 塑料件的表面质量分析…………………………………………………………4

3.4 塑料件的结构分析………………………………………………………………4

4 成型设备的选择和成型工艺的制定……………………………………………………5

4.1 成型参数的确定…………………………………………………………………5

4.2 塑件的体积和重量的计算………………………………………………………6

4.3 模具所需塑料熔体注射量………………………………………………………6

4.4 锁模力的计算……………………………………………………………………6

4.5 设备选择…………………………………………………………………………7

4.6 塑料成型工艺卡…………………………………………………………………8

5 注射模设计……………………………………………………………………………8

5.1 可行性分析………………………………………………………………………8

5.2 确定模具的类型…………………………………………………………………10

5.3 确定模具的主要结构……………………………………………………………10

6 安装与试模……………………………………………………………………………30

6.1 模具的安装结构图………………………………………………………………30

6.2 模具工作过程……………………………………………………………………31

6.3 模具的安装试模…………………………………………………………………32

结论…………………………………………………………………………………………33

参考文献 …………………………………………………………………………………33

致谢…………………………………………………………………………………………34