设计简介

塑料把把手成型工艺与模具设计

摘要:本设计题目为塑料把手注射模设计,体现了把手类塑料零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者注塑模设计的基础知识,为设计更复杂的注塑模具做好了铺垫和吸取了更深刻的经验。

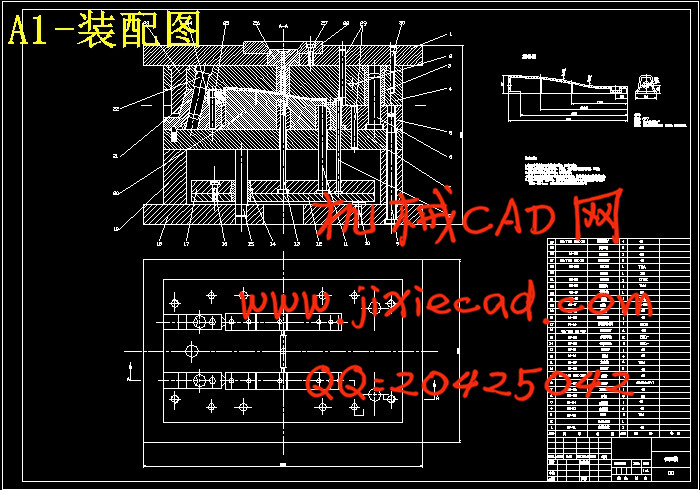

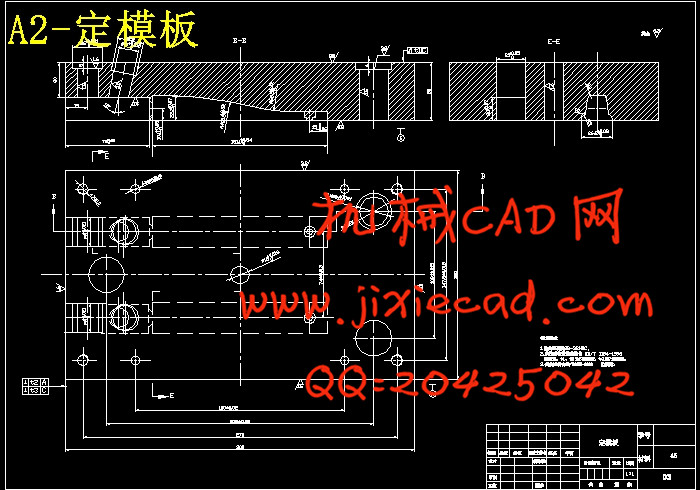

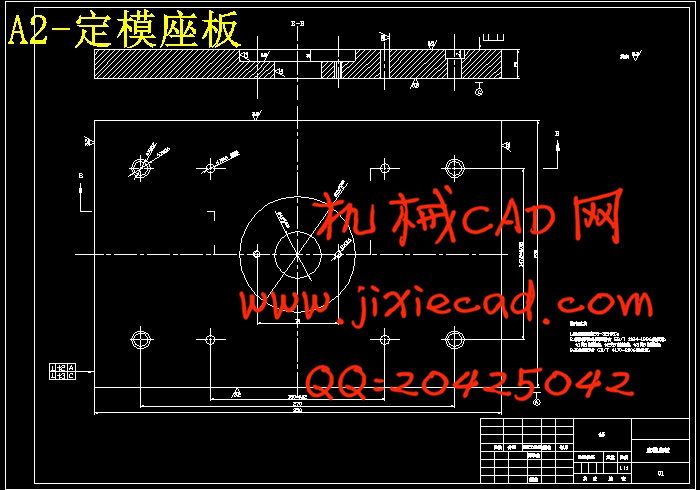

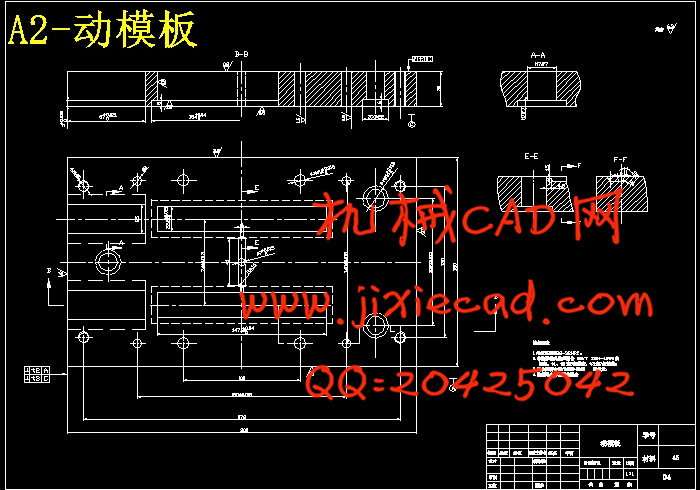

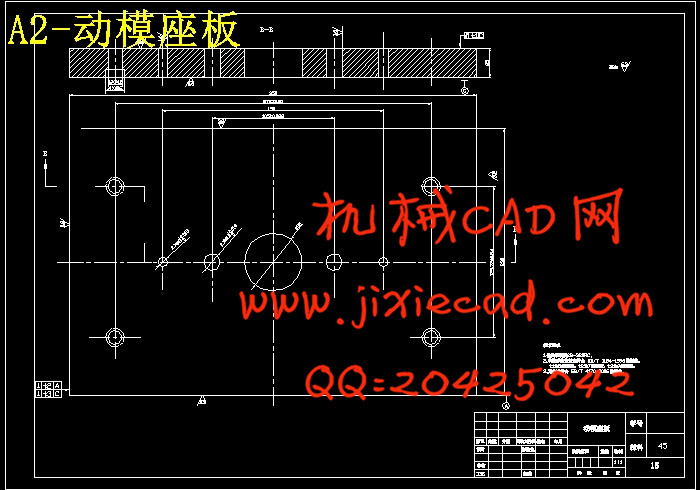

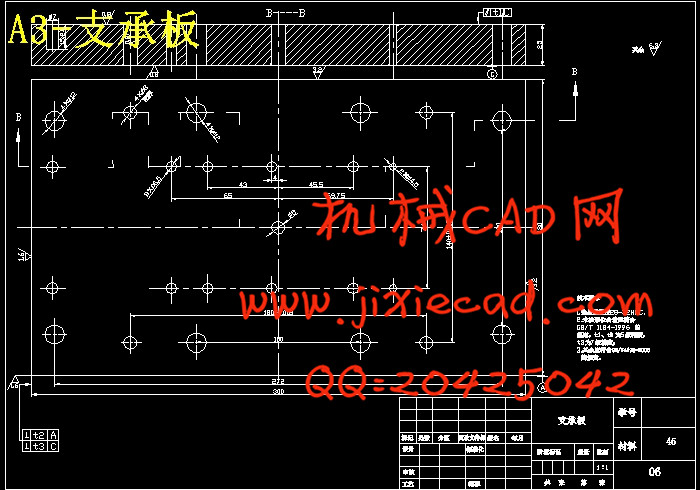

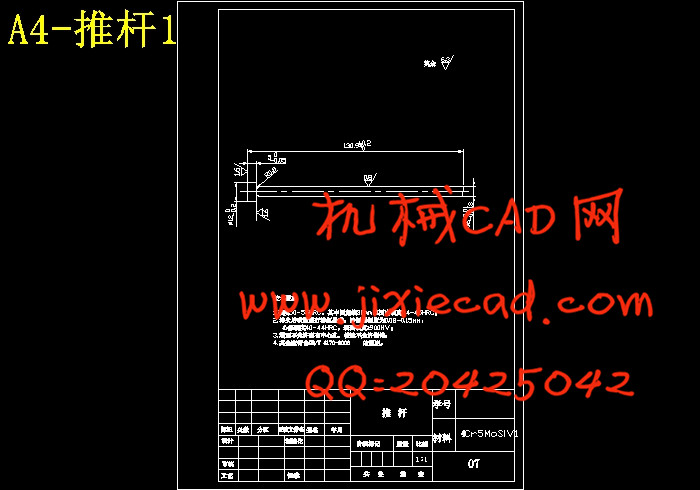

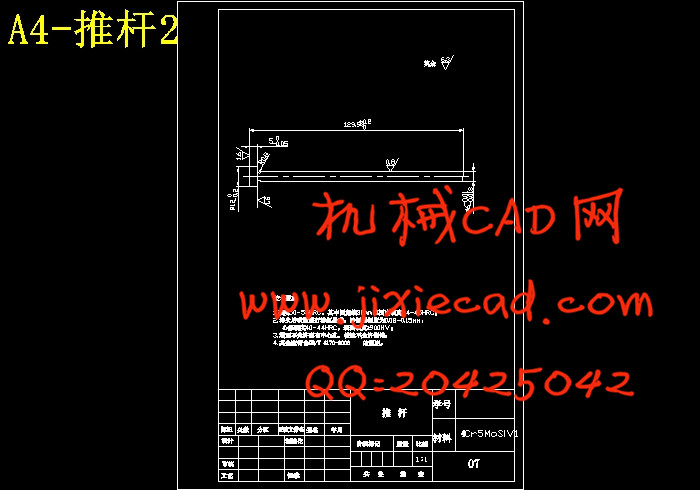

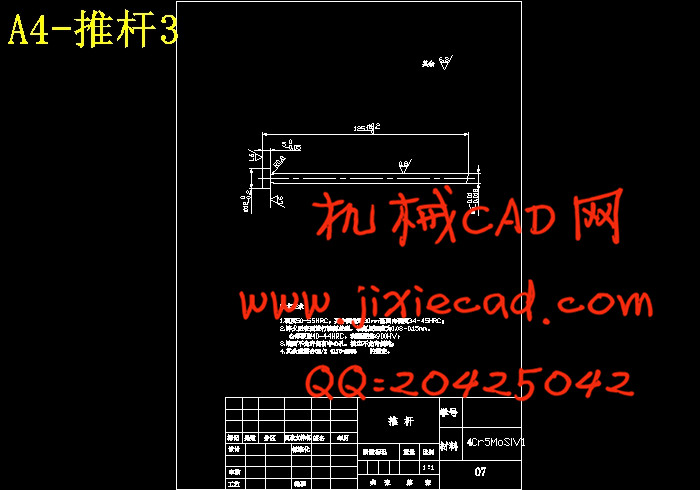

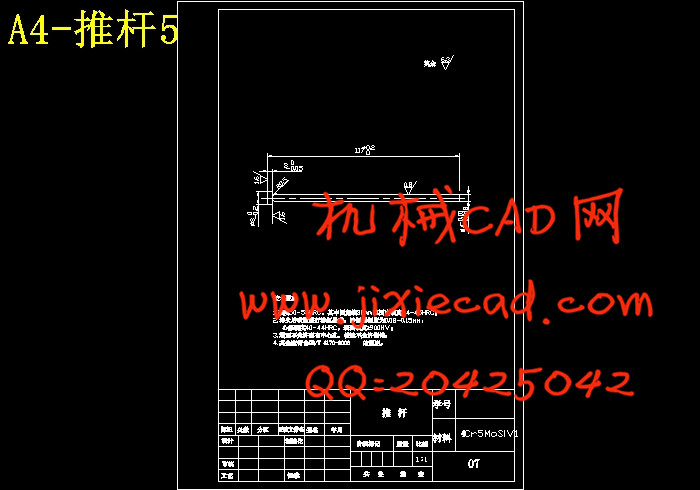

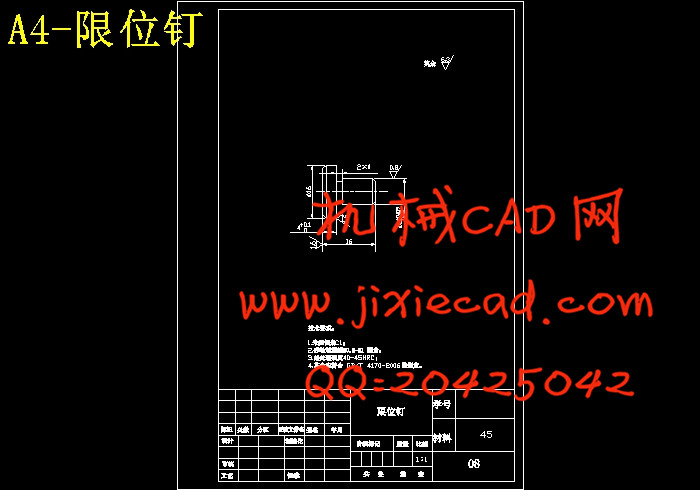

本设计通过对贮油杯盖结构工艺的正确分析,设计了一副一模两腔的塑料模具。详细地叙述了模具成型零件包括定模板、动模板、型芯等的设计与加工工艺过程,重要零件的工艺参数的选择与计算,推出机构与浇注系统以及其它结构的设计过程,并对试模与产品缺陷作了介绍。

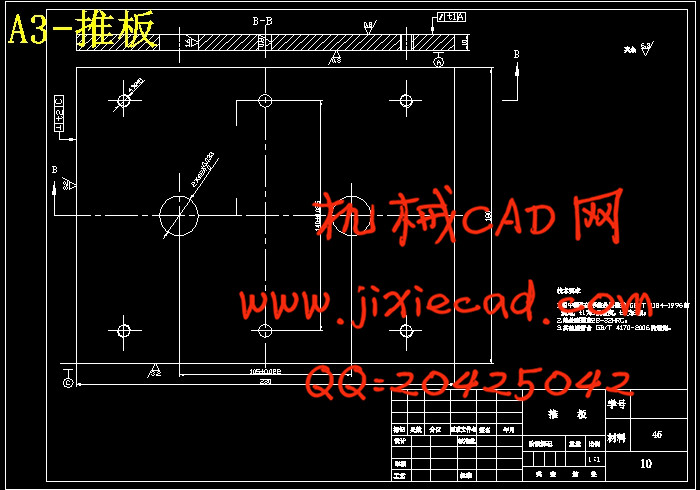

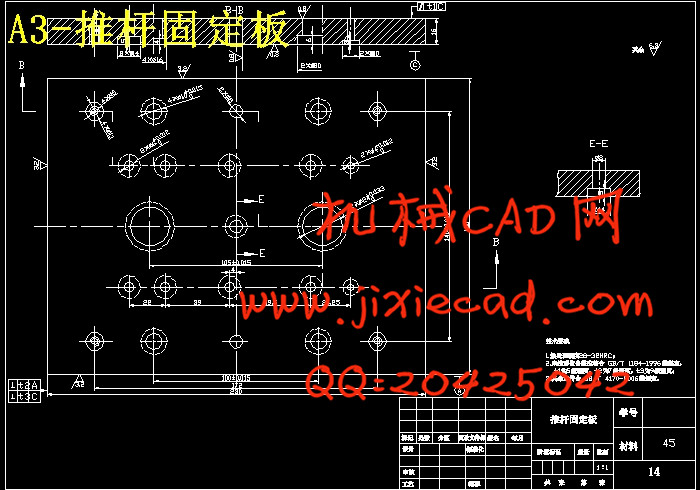

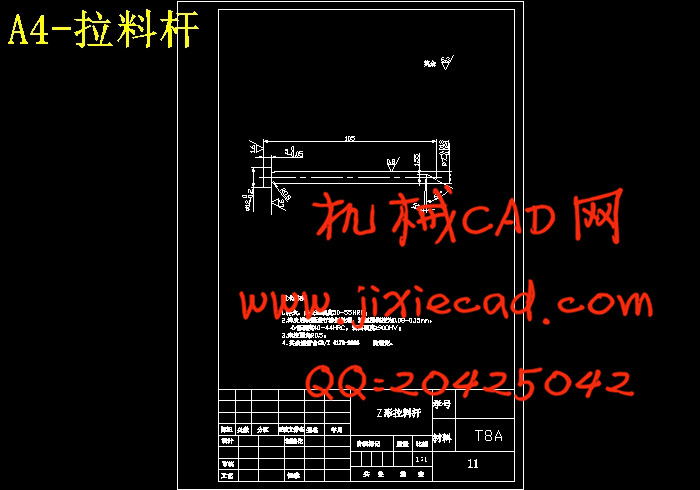

本设计在型芯固定板上应用了Z形拉料杆,开模时通过Z形拉料杆将浇注系统凝料从定模中拉出,然后通过推板脱模机构将塑件和浇注系统凝料从动模一侧脱下。这种机构脱模可靠,设计方便,且在模具中占用空间较小,非常适合在本副模具中使用。

关键词:注射模 浇口 推板 Z形拉料杆

Plastic forming process to handle and die design

Abstract:The design the topic for the emboby injection mold design of the handle, the handle reflects the type of plastic parts design, content and direction of the design of a certain significance. Through the design of the die parts to further enhance the design of injection mold designers the basic knowledge for the design of more complex injection molds and do a good job of paving the way to draw a more profound experience.

The design of oil storage lid on the process of the correct structural analysis, design of a four-cavity mold of a plastic mold. Detail molding die parts including the templates, dynamic templates, such as the design of core processes and processing, it is important parts of the process parameters of selection and terms, the introduction agencies and casting systems, as well as other structures of the design process, and test mode and product defects are introduced.

The fixed-core design in the application of the Z-shaped plate pull rod material, the mold through the Z-shaped pull rod will be expected condensate gating system in the material pulled out from the set mode, and then push the release plate and plastic parts will be gating system condensate is expected to take off the side of the driven mode. Such institutions Demoulding reliable, convenient design, and space in the mold of smaller, very suitable for the use of the die deputy.

Key words: Injection Mold gate Z-shaped pull rod

目 录

1绪论…………………………………………………………………………………………1

1.1国内模具的现状和发展趋势………………………………………………………1

1.1.1国内模具的现状………………………………………………………………………1

1.1.2国内模具的发展趋势…………………………………………………………………2

1.2国外模具的现状和发展趋势……………………………………………………………2

1.3塑料模具的现状和发展趋势………………………………………………………3

1.3.1塑料模的现状…………………………………………………………………3

1.3.2塑料模具的发展趋向…………………………………………………………………3

1.3.3我国塑料模具行业的主要问题………………………………………………………4

1.4毕业设计的目的………………………………………………………………………5

2 塑件的工艺性分析……………………………………………………………………6

2.1塑件的成型工艺性分析………………………………………………………6

2.1.1 塑件材料特性…………………………………………………………………………6

2.1.2 塑件材料成型性能……………………………………………………………………6

2.2塑件成型工艺参数的确定………………………………………………………………6

3 模具的结构设计…………………………………………………………………………8

3.1模具的基本结构…………………………………………………………………8

3.2确定型腔数目及布置…………………………………………………………………8

3.3确定浇注系统…………………………………………………………………8

3.3.1主流道设计…………………………………………………………………9

3.3.2分流道设计…………………………………………………………………12

3.3.3冷料穴设计…………………………………………………………………12

3.3.4浇口设计…………………………………………………………………13

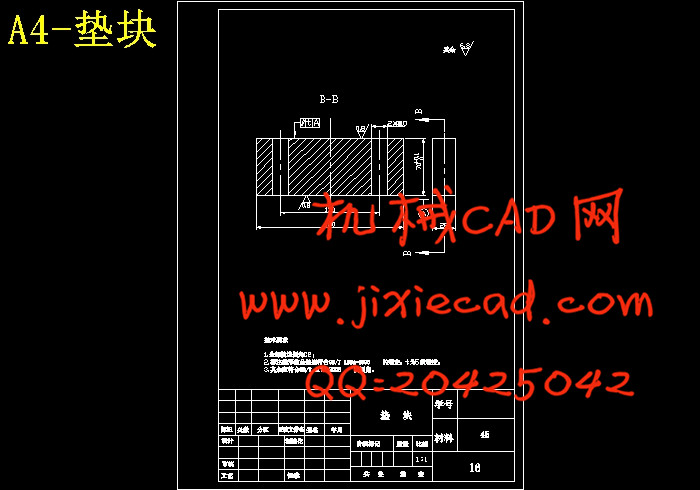

3.4成型零部件结构设计…………………………………………………………………14

3.4.1选择分型面…………………………………………………………………14

3.4.2注射模的排气…………………………………………………………………15

3.4.3凹模结构设计…………………………………………………………………15

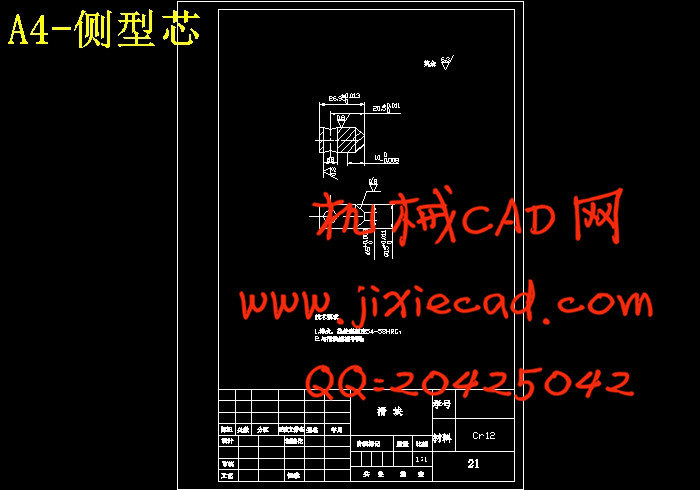

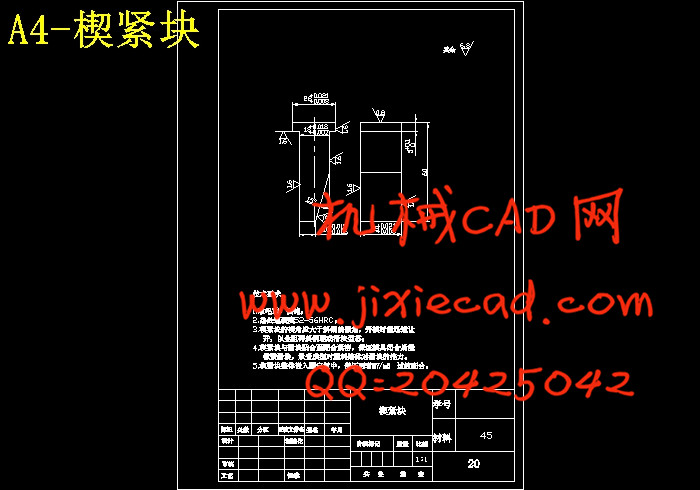

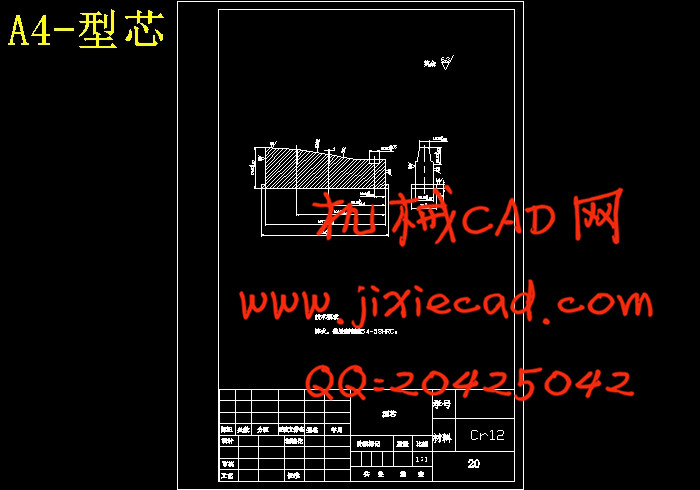

3.4.4型芯结构设计…………………………………………………………………15

3.4.5成型零部件工作尺寸的计算…………………………………………………………16

3.4.6成型零部件的壁厚计算………………………………………………………………18

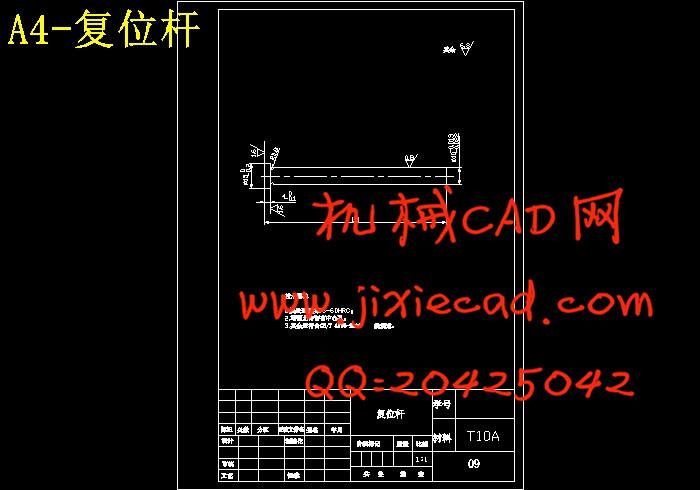

3.5确定推出方式…………………………………………………………………19

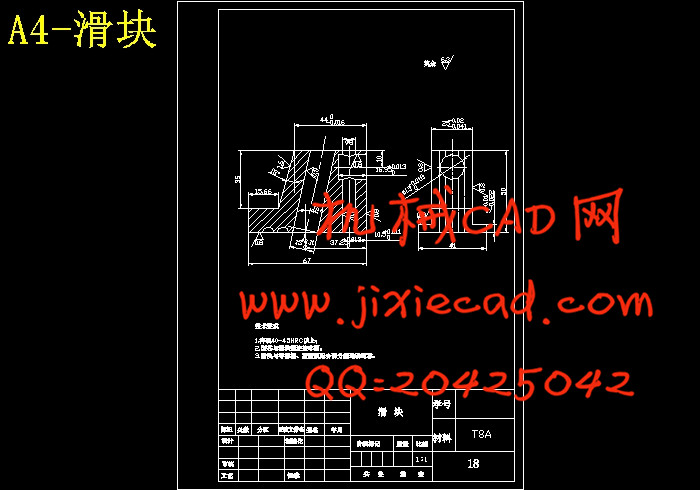

3.6侧向分型与抽芯机构设计………………………………………………………………21

3.6.1抽芯机构抽芯距和斜导柱长度的计算………………………………………………21

3.6.2斜销侧向分型与抽芯机构主要参数的确定…………………………………………22

3.6.3斜销侧向分型与抽芯机构的结构设计要点…………………………………………22

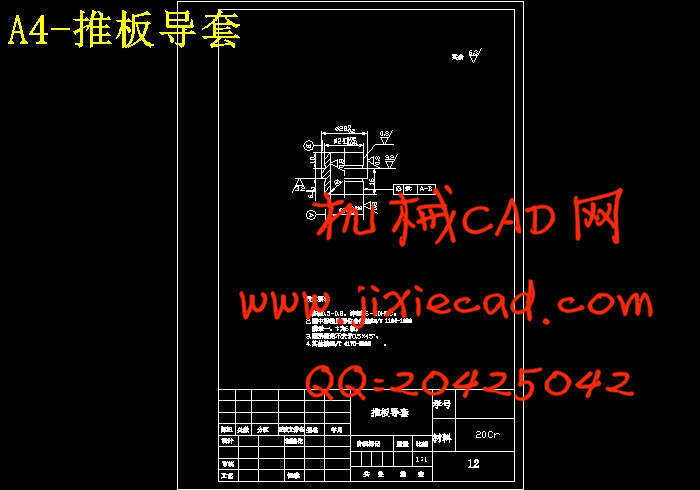

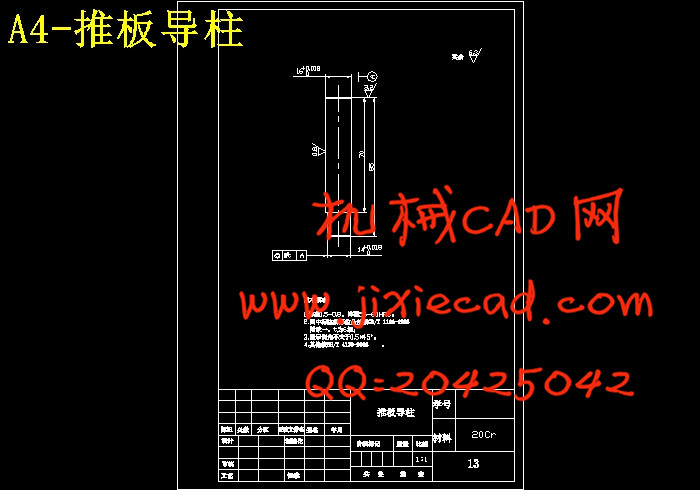

3.7合模导向机构设计………………………………………………………25

3.7.1导柱设计……………………………………………………………………25

3.7.2导套设计……………………………………………………………………26

3.8确定模温调节系统……………………………………………………………………26

4塑料成型设备的选取与校核……………………………………………………………28

4.1成型设备的选取……………………………………………………………………28

4.2注射机有关参数的校核…………………………………………………………………28

5 模具的装配………………………………………………………………………………30

5.1装配技术要求…………………………………………………………………30

5.1.1模具外观的装配技术要求……………………………………………………………30

5.1.2成型零件及浇注系统的装配技术要求………………………………………………30

5.1.3活动零件的装配技术要求………………………………………………………31

5.1.4锁紧及紧固零件的装配技术要求…………………………………………………31

5.1.5顶出机构的装配技术要求…………………………………………………………31

5.1.6导向机构的装配技术要求…………………………………………………………31

5.1.7加热冷却系统的装配技术要求……………………………………………………31

5.2模具装配与安装…………………………………………………………32

5.2.1模具的装配………………………………………………………………………32

5.2.2模具的安装…………………………………………………………………33

5.3试模…………………………………………………………………………34

5.3.1调试料筒和喷嘴温度……………………………………………………………34

5.3.2成型缺陷……………………………………………………………………34

结束语………………………………………………………………………………36

致谢 …………………………………………………………………………………………39

参考文献……………………………………………………………………………………40

摘要:本设计题目为塑料把手注射模设计,体现了把手类塑料零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者注塑模设计的基础知识,为设计更复杂的注塑模具做好了铺垫和吸取了更深刻的经验。

本设计通过对贮油杯盖结构工艺的正确分析,设计了一副一模两腔的塑料模具。详细地叙述了模具成型零件包括定模板、动模板、型芯等的设计与加工工艺过程,重要零件的工艺参数的选择与计算,推出机构与浇注系统以及其它结构的设计过程,并对试模与产品缺陷作了介绍。

本设计在型芯固定板上应用了Z形拉料杆,开模时通过Z形拉料杆将浇注系统凝料从定模中拉出,然后通过推板脱模机构将塑件和浇注系统凝料从动模一侧脱下。这种机构脱模可靠,设计方便,且在模具中占用空间较小,非常适合在本副模具中使用。

关键词:注射模 浇口 推板 Z形拉料杆

Plastic forming process to handle and die design

Abstract:The design the topic for the emboby injection mold design of the handle, the handle reflects the type of plastic parts design, content and direction of the design of a certain significance. Through the design of the die parts to further enhance the design of injection mold designers the basic knowledge for the design of more complex injection molds and do a good job of paving the way to draw a more profound experience.

The design of oil storage lid on the process of the correct structural analysis, design of a four-cavity mold of a plastic mold. Detail molding die parts including the templates, dynamic templates, such as the design of core processes and processing, it is important parts of the process parameters of selection and terms, the introduction agencies and casting systems, as well as other structures of the design process, and test mode and product defects are introduced.

The fixed-core design in the application of the Z-shaped plate pull rod material, the mold through the Z-shaped pull rod will be expected condensate gating system in the material pulled out from the set mode, and then push the release plate and plastic parts will be gating system condensate is expected to take off the side of the driven mode. Such institutions Demoulding reliable, convenient design, and space in the mold of smaller, very suitable for the use of the die deputy.

Key words: Injection Mold gate Z-shaped pull rod

目 录

1绪论…………………………………………………………………………………………1

1.1国内模具的现状和发展趋势………………………………………………………1

1.1.1国内模具的现状………………………………………………………………………1

1.1.2国内模具的发展趋势…………………………………………………………………2

1.2国外模具的现状和发展趋势……………………………………………………………2

1.3塑料模具的现状和发展趋势………………………………………………………3

1.3.1塑料模的现状…………………………………………………………………3

1.3.2塑料模具的发展趋向…………………………………………………………………3

1.3.3我国塑料模具行业的主要问题………………………………………………………4

1.4毕业设计的目的………………………………………………………………………5

2 塑件的工艺性分析……………………………………………………………………6

2.1塑件的成型工艺性分析………………………………………………………6

2.1.1 塑件材料特性…………………………………………………………………………6

2.1.2 塑件材料成型性能……………………………………………………………………6

2.2塑件成型工艺参数的确定………………………………………………………………6

3 模具的结构设计…………………………………………………………………………8

3.1模具的基本结构…………………………………………………………………8

3.2确定型腔数目及布置…………………………………………………………………8

3.3确定浇注系统…………………………………………………………………8

3.3.1主流道设计…………………………………………………………………9

3.3.2分流道设计…………………………………………………………………12

3.3.3冷料穴设计…………………………………………………………………12

3.3.4浇口设计…………………………………………………………………13

3.4成型零部件结构设计…………………………………………………………………14

3.4.1选择分型面…………………………………………………………………14

3.4.2注射模的排气…………………………………………………………………15

3.4.3凹模结构设计…………………………………………………………………15

3.4.4型芯结构设计…………………………………………………………………15

3.4.5成型零部件工作尺寸的计算…………………………………………………………16

3.4.6成型零部件的壁厚计算………………………………………………………………18

3.5确定推出方式…………………………………………………………………19

3.6侧向分型与抽芯机构设计………………………………………………………………21

3.6.1抽芯机构抽芯距和斜导柱长度的计算………………………………………………21

3.6.2斜销侧向分型与抽芯机构主要参数的确定…………………………………………22

3.6.3斜销侧向分型与抽芯机构的结构设计要点…………………………………………22

3.7合模导向机构设计………………………………………………………25

3.7.1导柱设计……………………………………………………………………25

3.7.2导套设计……………………………………………………………………26

3.8确定模温调节系统……………………………………………………………………26

4塑料成型设备的选取与校核……………………………………………………………28

4.1成型设备的选取……………………………………………………………………28

4.2注射机有关参数的校核…………………………………………………………………28

5 模具的装配………………………………………………………………………………30

5.1装配技术要求…………………………………………………………………30

5.1.1模具外观的装配技术要求……………………………………………………………30

5.1.2成型零件及浇注系统的装配技术要求………………………………………………30

5.1.3活动零件的装配技术要求………………………………………………………31

5.1.4锁紧及紧固零件的装配技术要求…………………………………………………31

5.1.5顶出机构的装配技术要求…………………………………………………………31

5.1.6导向机构的装配技术要求…………………………………………………………31

5.1.7加热冷却系统的装配技术要求……………………………………………………31

5.2模具装配与安装…………………………………………………………32

5.2.1模具的装配………………………………………………………………………32

5.2.2模具的安装…………………………………………………………………33

5.3试模…………………………………………………………………………34

5.3.1调试料筒和喷嘴温度……………………………………………………………34

5.3.2成型缺陷……………………………………………………………………34

结束语………………………………………………………………………………36

致谢 …………………………………………………………………………………………39

参考文献……………………………………………………………………………………40