设计简介

摘要;模具作为提高生产率,减少材料和消耗,降低产品成本,提高产品质量和市场竞争力的重要手段,已越来越受到各工业部门的重视。随着工业技术不断向前发展。随着全球经济的发展,模具工业在国民经济中所发挥的作用越来越明显,模具水平的高低直接影响产品的质量及生产效率。

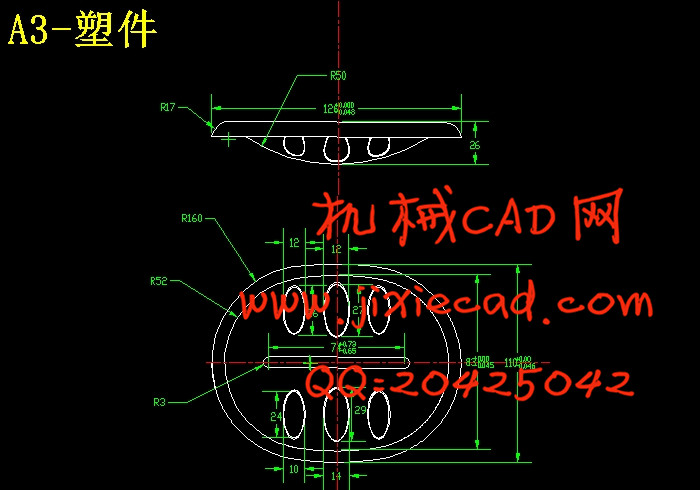

本次毕设是完成肥皂盒注塑模设计,肥皂盒在我们的生活中非常的普遍,几乎每家都要用到。市场上也有各种各样的肥皂盒,形状各异,有些是把肥皂盒做成水果造型,有些是动植物造型,来吸引顾客的目光,以引发人们的购买欲。此次设计的肥皂盒的结构较简单,但在设计时考虑其应用,还相应的做了些曲面,所以曲面结构较多,计算也就较多.在生活中,我们把肥皂放在盒上的时候,常常会因肥皂盒内积水而使肥皂软化掉,这样就会降低肥皂的使用寿命。也有些肥皂盒在下盖底部打孔,使水容易流出。

在设计过程中需要确定该塑件的注塑成型方案并进行了注射模设计方面的相关计算,并用mastercam对零件进行造型和生成数控加工程序并进行仿真加工。本次设计是依靠书本上的理论和实践的综合性设计。这就需要大量书籍和老师的指导与理论的结合使得设计日趋完善。PROE是现在常用的一种软件,使用它可以进行造型和数控程序的生成。

关键词:注塑模 实体造型 数控仿真加工 MASTERCAM

Abstract;Die as a means to increase productivity, reduce consumption of materials and to reduce product cost, improve product quality and market competitiveness of an important means to have more and more attention to the industrial sector. With the continuous development of industrial technology. With the global economic development, the mold industry in the national economy, the role played by more and more obvious, die level of a direct impact on product quality and production efficiency.

The complete set is to complete the design of injection mold soapbox, soapbox in our lives is a universal, almost every family should be used. The market also has a wide range of soapbox, various shapes, some shapes to soapbox into fruit, some form of animals and plants to attract the attention of customers in order to lead people to purchase. The design of the structure of the soapbox relatively simple, but when considered in the design of their application, but also made some of the corresponding surface, so more surface structure, the calculation will be more. In life, we put the soap box time, often because of soapbox soap to soften water out, which would reduce the life of the soap. Soapbox some cover at the bottom of the next hole, so that outflow of water easily.

During the design process to determine the need for injection molding plastic parts of the program and the design of the injection mold-related terms, and using PROE modeling of parts and generate NC machining simulation and processing procedures.

The book is designed to rely on the theory and practice of integrated design. This requires a large number of books and teacher's guide with a combination of theory makes the design better. PROE is now a commonly used software, use it and shape can be generated NC program.

Key words: CNC ;Machining ;Injection Modeling; CAD ;

目录

1 前言………………………………………………………………………………(01)

1.1 模具业发展现状……………………………………………………………(01)

1.2 CAD/ CAM的发展情况………………………………………………………(01)

1.3 模具CAD/CAM技术的优越性………………………………………………(02)

1.4 我国模具技术的现状及发展趋势…………………………………………(03)

1.5 本课题的研究内容及实验方案……………………………………………(04)

2 肥皂盒塑件的分析与注塑成型原理 …………………………………(05)

2.1 塑件的分析与成型工艺……………………………………………………(05)

2.1.1 塑件的工艺分析……………………………………………………………(05)

2.1.2 塑料的分类与性能…………………………………………………………(06)

2.1.3 注射成型原理及分类………………………………………………………(06)

2.1.4 注射机的分类………………………………………………………………(07)

2.1.5 注射机技术参数……………………………………………………………(08)

3 肥皂盒注塑模的设计………………………………………………………(09)

3.1 初步确定型腔数目…………………………………………………………(09)

3.2 注射机的选择………………………………………………………………(09)

3.2.1 塑件体积的计算……………………………………………………………(09)

3.2.2 按注射机的最大注射量确定型腔数目……………………………………(09)

3.2.3 估算浇注系统体积…………………………………………………………(10)

4 浇注系统的设计 ……………………………………………………………(11)

4.1 主流道的设计………………………………………………………………(11)

4.2 分流道的设计………………………………………………………………(12)

4.3 分型面的选择设计原理……………………………………………………(12)

4.4 浇口的设计…………………………………………………………………(13)

4.5 冷料穴的设计………………………………………………………………(14)

4.6 排气系统的设计……………………………………………………………(14)

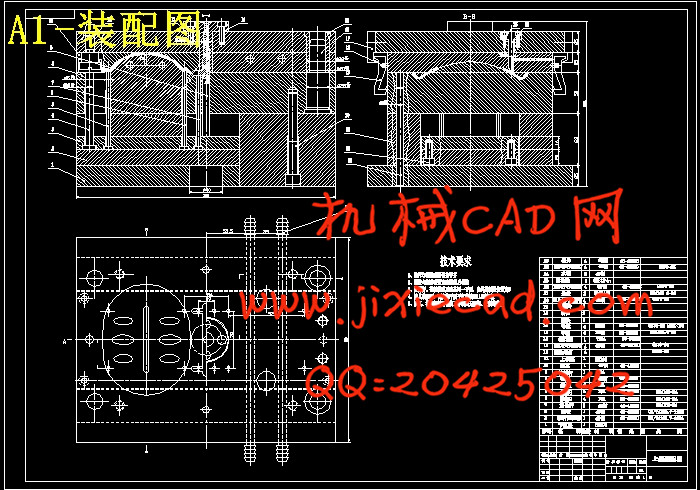

5 注塑模模架设计 ……………………………………………………………(15)

6 注塑模模架设计 ……………………………………………………………(16)

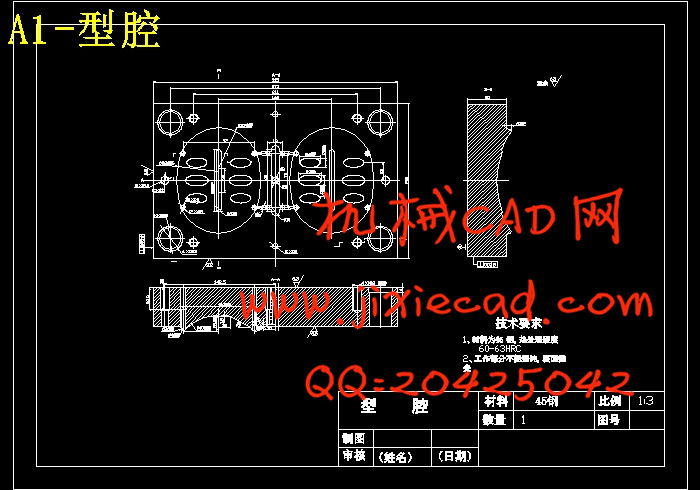

6.1 型腔、型芯工作尺寸计算……………………………………………………(16)

6.1.1 型腔尺寸计算………………………………………………………………(17)

6.1.2 型芯尺寸计算………………………………………………………………(18)

6.2 导向机构的设计……………………………………………………………(19)

6.2.1 导柱的设计…………………………………………………………………(19)

6.2.2 导套的结构设计……………………………………………………………(19)

6.2.3 推出机构的设计……………………………………………………………(19)

6.2.4 推件力的计算………………………………………………………………(20)

6.2.5 推杆的设计…………………………………………………………………(20)

7 模具温度调节系统的设计 ………………………………………………(21)

7.1 求塑件在硬化时每小时释放的Q…………………………………………(21)

7.2 求冷却水的体积流量V……………………………………………………(21)8 校核………………………………………………………………………………(22)

8.1 整体式原形型腔壁厚度的计算……………………………………………(22)

8.1.1 按刚度条件计算……………………………………………………………(22)

8.1.2 整体式圆形型腔底版厚度的计算…………………………………………(22)

8.2 注射机有关工艺参数的校核………………………………………………(22)

8.3 模具厚度H与注射机闭和和高度…………………………………………(23)

9 模具型芯、型腔的三维造型与数控仿真加工………………………(24)

9.1 Mastercam软件简介………………………………………………………(25)

9.1.1 Mastercam软件的特点与功能……………………………………………(26)

9.1.2 三维设计与加工系统………………………………………………………(27)

9.2 模具型芯、型腔型面三维造型……………………………………………(28)

9.3 模具型腔的数控仿真加工…………………………………………………(28)

9.3.1 加工路线的确定……………………………………………………………(28)

9.3.2 部分工序加工流程及数控程序的生成……………………………………(28)

9.4 型芯的数控加工……………………………………………………………(33)

9.4.1 加工路线的确定……………………………………………………………(33)

9.4.2 工序加工方法的确定及数控程序…………………………………………(33)

结论……………………………………………………………………………………(37)

参考文献……………………………………………………………………………(39)

致 谢……………………………………………………………………………(40)

本次毕设是完成肥皂盒注塑模设计,肥皂盒在我们的生活中非常的普遍,几乎每家都要用到。市场上也有各种各样的肥皂盒,形状各异,有些是把肥皂盒做成水果造型,有些是动植物造型,来吸引顾客的目光,以引发人们的购买欲。此次设计的肥皂盒的结构较简单,但在设计时考虑其应用,还相应的做了些曲面,所以曲面结构较多,计算也就较多.在生活中,我们把肥皂放在盒上的时候,常常会因肥皂盒内积水而使肥皂软化掉,这样就会降低肥皂的使用寿命。也有些肥皂盒在下盖底部打孔,使水容易流出。

在设计过程中需要确定该塑件的注塑成型方案并进行了注射模设计方面的相关计算,并用mastercam对零件进行造型和生成数控加工程序并进行仿真加工。本次设计是依靠书本上的理论和实践的综合性设计。这就需要大量书籍和老师的指导与理论的结合使得设计日趋完善。PROE是现在常用的一种软件,使用它可以进行造型和数控程序的生成。

关键词:注塑模 实体造型 数控仿真加工 MASTERCAM

Abstract;Die as a means to increase productivity, reduce consumption of materials and to reduce product cost, improve product quality and market competitiveness of an important means to have more and more attention to the industrial sector. With the continuous development of industrial technology. With the global economic development, the mold industry in the national economy, the role played by more and more obvious, die level of a direct impact on product quality and production efficiency.

The complete set is to complete the design of injection mold soapbox, soapbox in our lives is a universal, almost every family should be used. The market also has a wide range of soapbox, various shapes, some shapes to soapbox into fruit, some form of animals and plants to attract the attention of customers in order to lead people to purchase. The design of the structure of the soapbox relatively simple, but when considered in the design of their application, but also made some of the corresponding surface, so more surface structure, the calculation will be more. In life, we put the soap box time, often because of soapbox soap to soften water out, which would reduce the life of the soap. Soapbox some cover at the bottom of the next hole, so that outflow of water easily.

During the design process to determine the need for injection molding plastic parts of the program and the design of the injection mold-related terms, and using PROE modeling of parts and generate NC machining simulation and processing procedures.

The book is designed to rely on the theory and practice of integrated design. This requires a large number of books and teacher's guide with a combination of theory makes the design better. PROE is now a commonly used software, use it and shape can be generated NC program.

Key words: CNC ;Machining ;Injection Modeling; CAD ;

目录

1 前言………………………………………………………………………………(01)

1.1 模具业发展现状……………………………………………………………(01)

1.2 CAD/ CAM的发展情况………………………………………………………(01)

1.3 模具CAD/CAM技术的优越性………………………………………………(02)

1.4 我国模具技术的现状及发展趋势…………………………………………(03)

1.5 本课题的研究内容及实验方案……………………………………………(04)

2 肥皂盒塑件的分析与注塑成型原理 …………………………………(05)

2.1 塑件的分析与成型工艺……………………………………………………(05)

2.1.1 塑件的工艺分析……………………………………………………………(05)

2.1.2 塑料的分类与性能…………………………………………………………(06)

2.1.3 注射成型原理及分类………………………………………………………(06)

2.1.4 注射机的分类………………………………………………………………(07)

2.1.5 注射机技术参数……………………………………………………………(08)

3 肥皂盒注塑模的设计………………………………………………………(09)

3.1 初步确定型腔数目…………………………………………………………(09)

3.2 注射机的选择………………………………………………………………(09)

3.2.1 塑件体积的计算……………………………………………………………(09)

3.2.2 按注射机的最大注射量确定型腔数目……………………………………(09)

3.2.3 估算浇注系统体积…………………………………………………………(10)

4 浇注系统的设计 ……………………………………………………………(11)

4.1 主流道的设计………………………………………………………………(11)

4.2 分流道的设计………………………………………………………………(12)

4.3 分型面的选择设计原理……………………………………………………(12)

4.4 浇口的设计…………………………………………………………………(13)

4.5 冷料穴的设计………………………………………………………………(14)

4.6 排气系统的设计……………………………………………………………(14)

5 注塑模模架设计 ……………………………………………………………(15)

6 注塑模模架设计 ……………………………………………………………(16)

6.1 型腔、型芯工作尺寸计算……………………………………………………(16)

6.1.1 型腔尺寸计算………………………………………………………………(17)

6.1.2 型芯尺寸计算………………………………………………………………(18)

6.2 导向机构的设计……………………………………………………………(19)

6.2.1 导柱的设计…………………………………………………………………(19)

6.2.2 导套的结构设计……………………………………………………………(19)

6.2.3 推出机构的设计……………………………………………………………(19)

6.2.4 推件力的计算………………………………………………………………(20)

6.2.5 推杆的设计…………………………………………………………………(20)

7 模具温度调节系统的设计 ………………………………………………(21)

7.1 求塑件在硬化时每小时释放的Q…………………………………………(21)

7.2 求冷却水的体积流量V……………………………………………………(21)8 校核………………………………………………………………………………(22)

8.1 整体式原形型腔壁厚度的计算……………………………………………(22)

8.1.1 按刚度条件计算……………………………………………………………(22)

8.1.2 整体式圆形型腔底版厚度的计算…………………………………………(22)

8.2 注射机有关工艺参数的校核………………………………………………(22)

8.3 模具厚度H与注射机闭和和高度…………………………………………(23)

9 模具型芯、型腔的三维造型与数控仿真加工………………………(24)

9.1 Mastercam软件简介………………………………………………………(25)

9.1.1 Mastercam软件的特点与功能……………………………………………(26)

9.1.2 三维设计与加工系统………………………………………………………(27)

9.2 模具型芯、型腔型面三维造型……………………………………………(28)

9.3 模具型腔的数控仿真加工…………………………………………………(28)

9.3.1 加工路线的确定……………………………………………………………(28)

9.3.2 部分工序加工流程及数控程序的生成……………………………………(28)

9.4 型芯的数控加工……………………………………………………………(33)

9.4.1 加工路线的确定……………………………………………………………(33)

9.4.2 工序加工方法的确定及数控程序…………………………………………(33)

结论……………………………………………………………………………………(37)

参考文献……………………………………………………………………………(39)

致 谢……………………………………………………………………………(40)