设计简介

塑料盖的成型工艺及注塑模设计

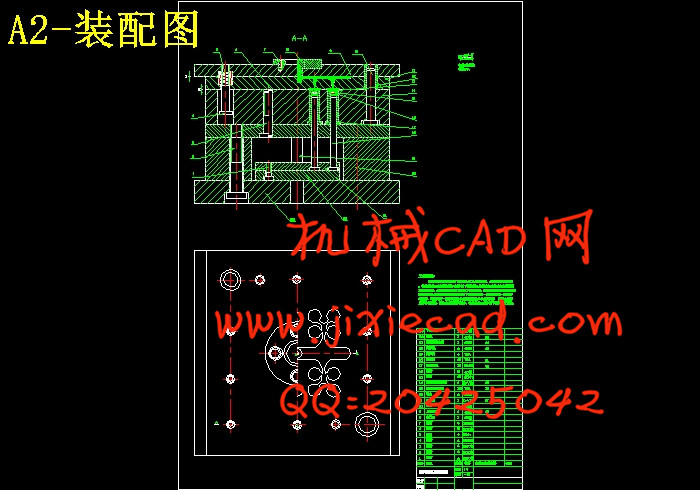

摘 要 从零件图上分析:该零件总体形状为一盒体高度方向仅与6mm。长度方向上有30mm。且在下端内壁里面有一个较小的外抽芯,抽芯空间较小,模具设计和制造难度均较大。由本塑件的形状不大且在塑件内部有向外凸起的回转结构在成型时不易脱模。传统上一般把内部的型腔做成两半的活动镶块用两个销钉一端过盈一端间隙配合将它们连接在一起脱模时连同活动型腔镶块一并顶出然后用手将它们分开,但此种设计不利于大批量,自动化生产的要求,因此在本副模具中对这种机构进行了改进,设计成了活动型腔的自动脱模机构。其结构设计方案如下:

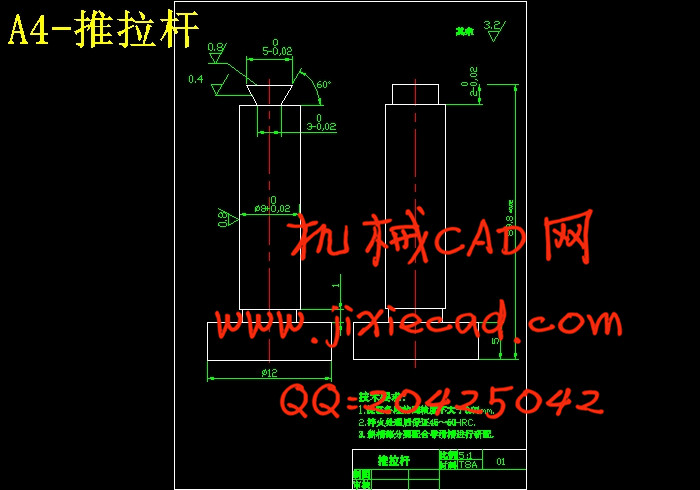

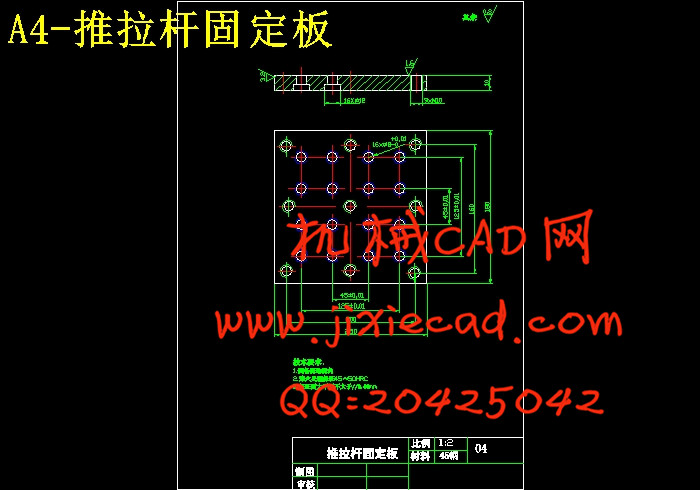

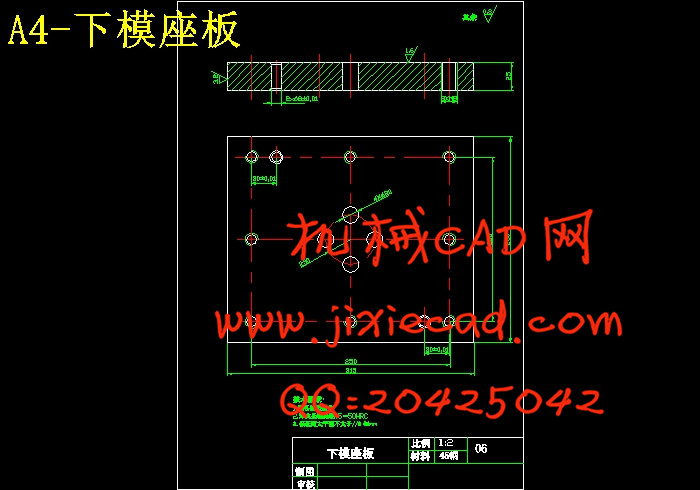

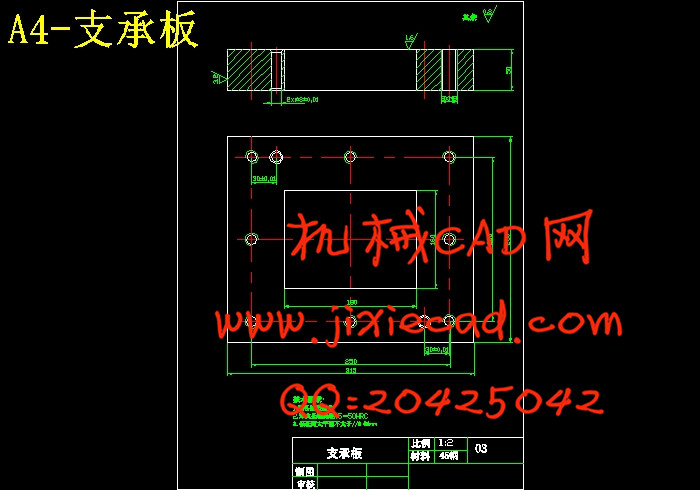

其工作原理:脱模时推拉杆推着活动型腔向前推进在弹簧弹力的作用下活动型腔沿套筒型芯的侧壁不断向两边张开,当张开当一定程度塑料在重力作用下自动脱落。顶出完成后模具闭合。在复位杆及推拉杆上弹簧受拉力的作用下活动型腔沿套筒型芯侧壁回到原来的位置。

关键词:活动型腔 套筒型芯 推拉杆 弹簧 外抽芯

The plastic covers takes shape the craft and the note molds the design

Abstract : Analyzes from the detail drawing: This components overall shape is box of bodies highly directions only with 6mm. In the length direction has 30mm. Also has small outside inside the lower extremity endophragm to pull out the core, pulls out the core space slightly, the mold design and the manufacture difficulty are big. By this models a shape not to be big also in models an interior has to the outside bulge rotation structure when taking shape not the easy drawing of patterns. In the tradition the cavity makes the interior two half activity to inlay generally the block as soon as to carry with two feather pieces the excessively full end play coordination them to connect when together drawing of patterns inlays the block together with the activity cavity one and goes against then separates with the hand them, but this kind of design does not favor the mass, the automated production request, therefore has made the improvement in this mold to this kind of organization, designed the activity cavity automatic drawing of patterns organization. Its structural design plan as follows:

Its principle of work: When drawing of patterns the push-pull rod pushes the activity cavity to prompt forward in under the spring tension function the activity cavity to two opens unceasingly along the sleeve core sidewall, when opens when the certain degree plastic automatically falls off under the action of gravity. After goes against completes the mold to close. The spring the activity cavity returns to on the release link and the push-pull rod under the pulling force function along the sleeve core sidewall the original position.

Key word:Activity cavity Sleeve core Push-pull rod

Spring Outside pulls out the core

绪 论 1

第一章 任务来源及设计意义 5

1.1 设计任务来源 5

1.2 设计目的及意义 6

第二章 零件的工艺性分析 8

2.1 塑件的原材料分析 8

2.2 塑件的结构和尺寸精度及表面质量分析 8

第三章 塑件的成型特性与工艺参数的确定 10

第四章 浇注系统设计 12

4.1 分型面的选择---------------------------------------------12

4.2 塑件的成型位置 12

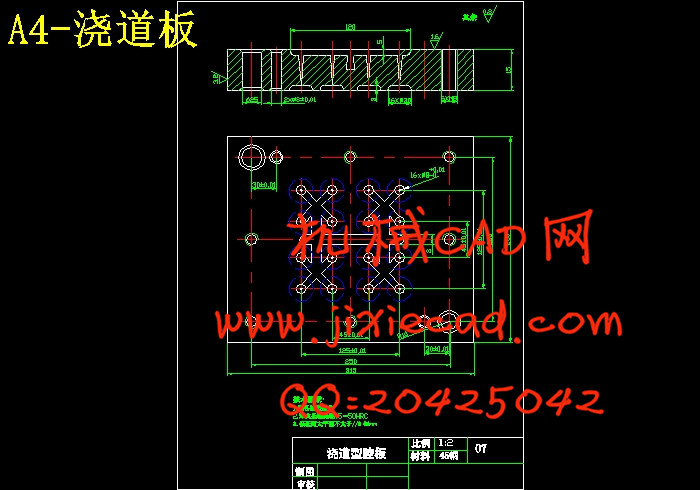

4.3 浇道设计 13

第五章 成型部件的工艺计算 15

5.1 型腔和型芯工作尺寸计算 15

5.2 模具加热与冷却系统的计算 18

第六章 模具闭合高度的确定--------------------------------- 19

第七章 注塑机有关参数的校核 20

第八章 编写主要零件加工工艺规程 ------------------------ 21

8.1 型芯套筒的加工工艺过程 21

8.2 型芯固定板的加工工艺过程 23

第九章 模具的安装与调试 25

9.1 模具的安装----------------------------- 25

9.2 模具的调试----------------------------- 26

设计总结 27

致谢 ------------------------------------------- 28

参考文献 29

摘 要 从零件图上分析:该零件总体形状为一盒体高度方向仅与6mm。长度方向上有30mm。且在下端内壁里面有一个较小的外抽芯,抽芯空间较小,模具设计和制造难度均较大。由本塑件的形状不大且在塑件内部有向外凸起的回转结构在成型时不易脱模。传统上一般把内部的型腔做成两半的活动镶块用两个销钉一端过盈一端间隙配合将它们连接在一起脱模时连同活动型腔镶块一并顶出然后用手将它们分开,但此种设计不利于大批量,自动化生产的要求,因此在本副模具中对这种机构进行了改进,设计成了活动型腔的自动脱模机构。其结构设计方案如下:

其工作原理:脱模时推拉杆推着活动型腔向前推进在弹簧弹力的作用下活动型腔沿套筒型芯的侧壁不断向两边张开,当张开当一定程度塑料在重力作用下自动脱落。顶出完成后模具闭合。在复位杆及推拉杆上弹簧受拉力的作用下活动型腔沿套筒型芯侧壁回到原来的位置。

关键词:活动型腔 套筒型芯 推拉杆 弹簧 外抽芯

The plastic covers takes shape the craft and the note molds the design

Abstract : Analyzes from the detail drawing: This components overall shape is box of bodies highly directions only with 6mm. In the length direction has 30mm. Also has small outside inside the lower extremity endophragm to pull out the core, pulls out the core space slightly, the mold design and the manufacture difficulty are big. By this models a shape not to be big also in models an interior has to the outside bulge rotation structure when taking shape not the easy drawing of patterns. In the tradition the cavity makes the interior two half activity to inlay generally the block as soon as to carry with two feather pieces the excessively full end play coordination them to connect when together drawing of patterns inlays the block together with the activity cavity one and goes against then separates with the hand them, but this kind of design does not favor the mass, the automated production request, therefore has made the improvement in this mold to this kind of organization, designed the activity cavity automatic drawing of patterns organization. Its structural design plan as follows:

Its principle of work: When drawing of patterns the push-pull rod pushes the activity cavity to prompt forward in under the spring tension function the activity cavity to two opens unceasingly along the sleeve core sidewall, when opens when the certain degree plastic automatically falls off under the action of gravity. After goes against completes the mold to close. The spring the activity cavity returns to on the release link and the push-pull rod under the pulling force function along the sleeve core sidewall the original position.

Key word:Activity cavity Sleeve core Push-pull rod

Spring Outside pulls out the core

绪 论 1

第一章 任务来源及设计意义 5

1.1 设计任务来源 5

1.2 设计目的及意义 6

第二章 零件的工艺性分析 8

2.1 塑件的原材料分析 8

2.2 塑件的结构和尺寸精度及表面质量分析 8

第三章 塑件的成型特性与工艺参数的确定 10

第四章 浇注系统设计 12

4.1 分型面的选择---------------------------------------------12

4.2 塑件的成型位置 12

4.3 浇道设计 13

第五章 成型部件的工艺计算 15

5.1 型腔和型芯工作尺寸计算 15

5.2 模具加热与冷却系统的计算 18

第六章 模具闭合高度的确定--------------------------------- 19

第七章 注塑机有关参数的校核 20

第八章 编写主要零件加工工艺规程 ------------------------ 21

8.1 型芯套筒的加工工艺过程 21

8.2 型芯固定板的加工工艺过程 23

第九章 模具的安装与调试 25

9.1 模具的安装----------------------------- 25

9.2 模具的调试----------------------------- 26

设计总结 27

致谢 ------------------------------------------- 28

参考文献 29