设计简介

摘 要

本设计说明书在在对塑料模具及塑料成型模具技术进行系统研究的基础上,对塑料水槽及其模具的设计做了全面的叙述。本设计design采用UG软件作为开发平台,不用草图sketch,可以在建模状态state下随心at your will得到所需要的结构形状form,提高improve了建模的精确性accuracy,加快了建模的速度。塑料水槽的设计的内容包括制品的材料选择,壁厚的确定,收缩率的确定以及用UG软件绘制的过程。塑料水槽的模具的设计,包括型腔数目的确定,型腔分形面及浇注系统的选择,注射成型模具零部件的设计及其它辅助结构件。在型腔数目的选择中,采用了一模四腔的设计方案,成型费用达到了最佳。

关键词:模具;UG 软件系统;塑料水槽;塑料成型模具;模具设计

ABSTRACT

On the basis of the systemic study of plastic mould and technology of the mould for plastics, this paper makes a depiction of the designs of the plastic flume and its mould. In my design, UG is used as a modeling tool. Without sketch, UG can set up the model at your will to improve the modeling accuracy and speed the modeling. The flume’s design includes the selection of the material, thickness, contractibility and how to use UG to plot it. The mould’s design includes the selection of the cavity’ number, the cavity’ fractal face and moulding system; in addition, this design includes the designs of injecting mould’ accessory and other parts. Especially, in the selection of the cavity’ number, I adopt the plan of four cavities in a mould in order to make the charge least.

Key words: mould ¨ UG system; plastic flume; mould for plastics; mould’ design

目 录

0 引言 ……………………………………………………………… 1

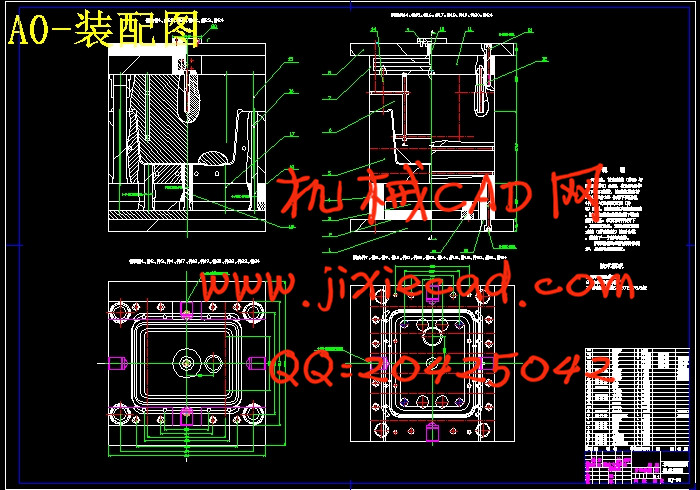

1 水槽及其注塑模具设计总体方案……………………………………… 3

1.1 总体方案论证 ………………………………………………………… 3

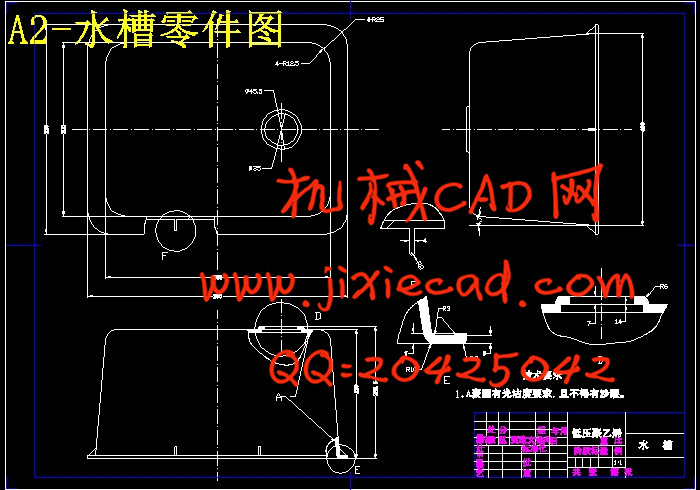

2 水槽设计部分 ………………………………………………………… 4

2.1 UG软件设计部分 ………………………………………………… 4

2.2 塑料水槽的参数设定 ………………………………………………… 6

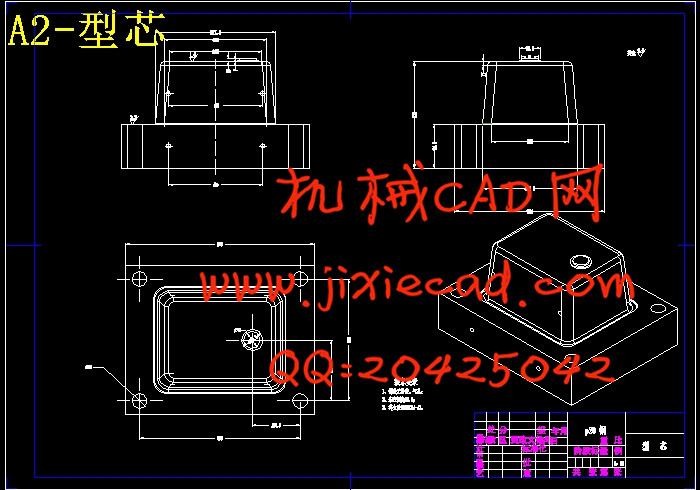

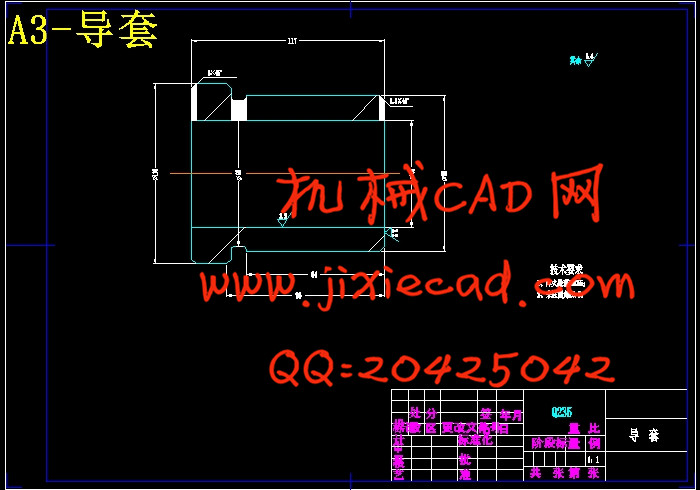

3 水槽模具设计部分 …………………………………………………… 11

3.1 确定型腔数目 ………………………………………………………… 11

3.2 型腔分型面及浇注系统 ……………………………………………… 14

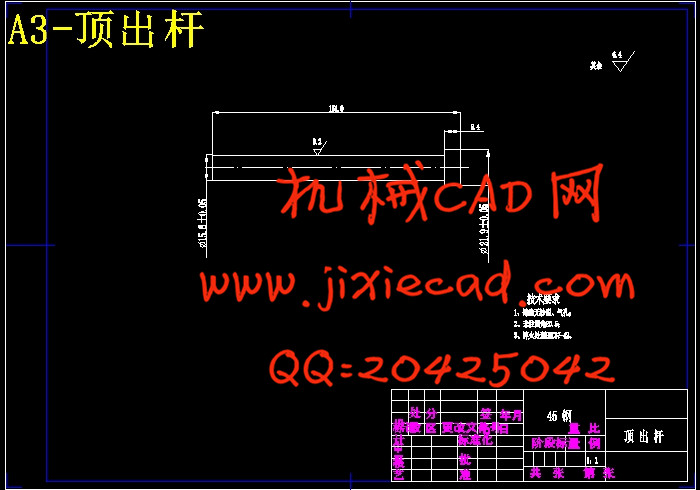

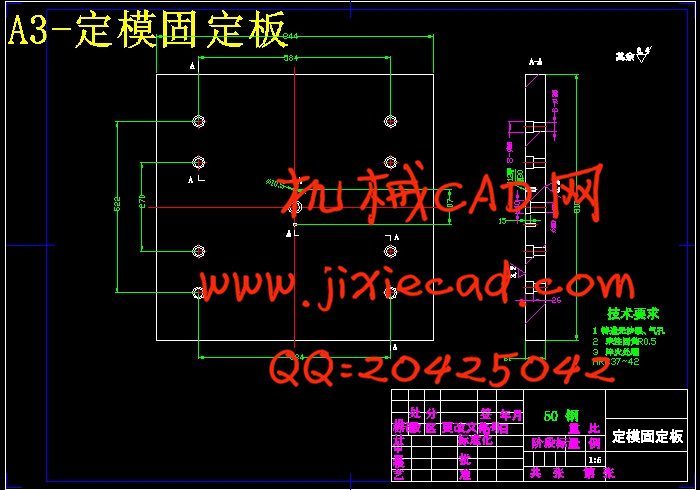

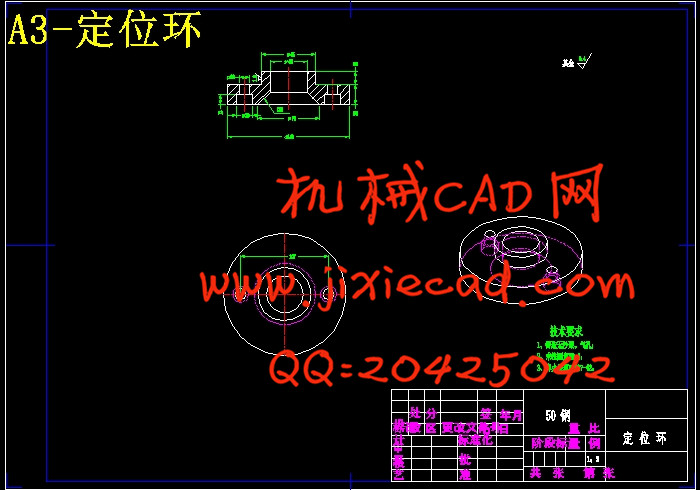

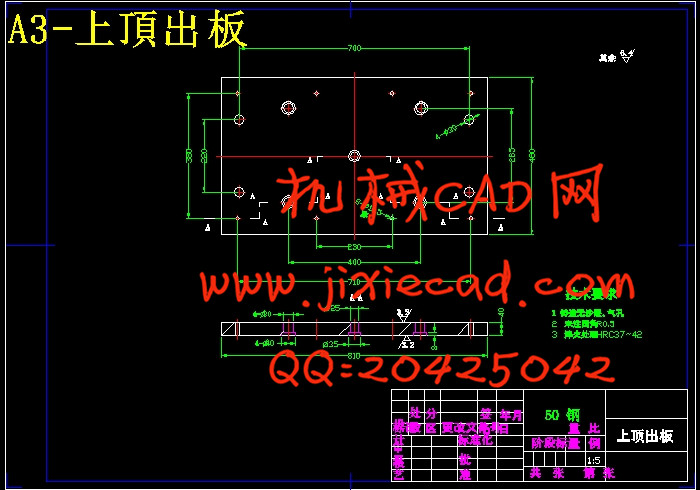

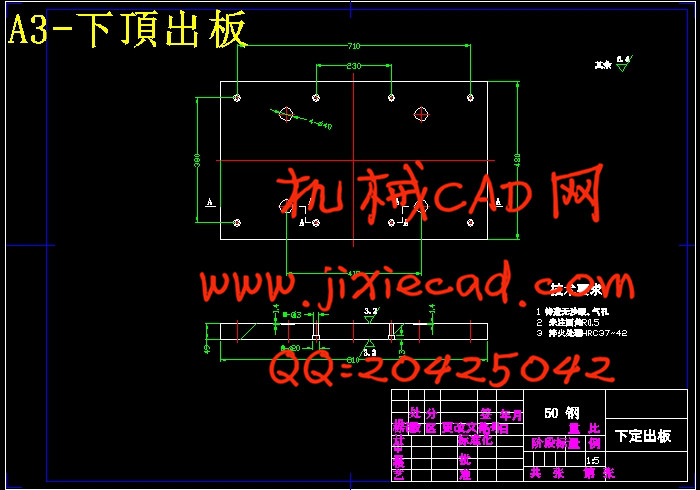

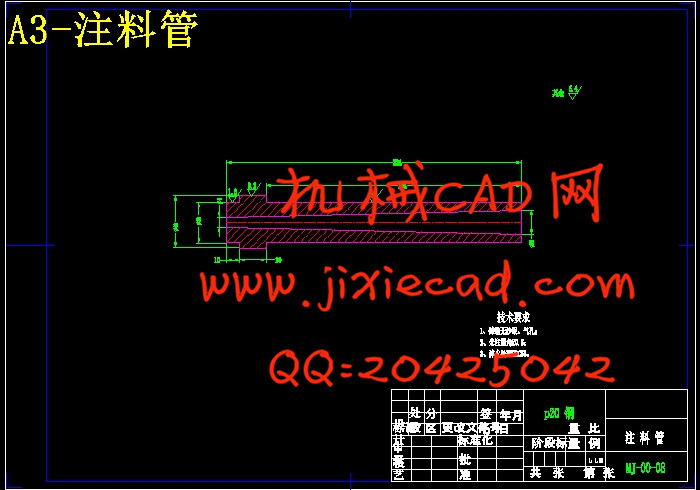

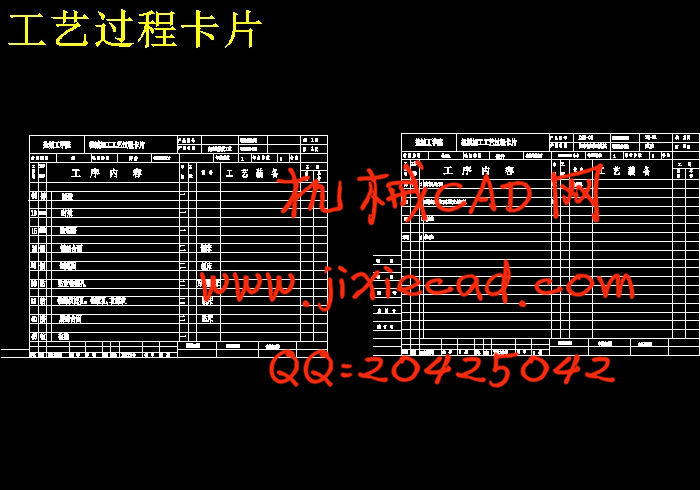

3.3 注射成型模具零部件的设计 ………………………………………… 16

3.4 其它辅助结构件 …………………………………………………… 21

3.5 脱模机构 ……………………………………………………………… 22

3.6 复位机构 ……………………………………………………………… 22

3.7 预期结果 ……………………………………………………………… 22

4 结论 …………………………………………………………………… 23

致谢 ………………………………………………………………………… 24

参考文献 …………………………………………………………………… 25

本设计说明书在在对塑料模具及塑料成型模具技术进行系统研究的基础上,对塑料水槽及其模具的设计做了全面的叙述。本设计design采用UG软件作为开发平台,不用草图sketch,可以在建模状态state下随心at your will得到所需要的结构形状form,提高improve了建模的精确性accuracy,加快了建模的速度。塑料水槽的设计的内容包括制品的材料选择,壁厚的确定,收缩率的确定以及用UG软件绘制的过程。塑料水槽的模具的设计,包括型腔数目的确定,型腔分形面及浇注系统的选择,注射成型模具零部件的设计及其它辅助结构件。在型腔数目的选择中,采用了一模四腔的设计方案,成型费用达到了最佳。

关键词:模具;UG 软件系统;塑料水槽;塑料成型模具;模具设计

ABSTRACT

On the basis of the systemic study of plastic mould and technology of the mould for plastics, this paper makes a depiction of the designs of the plastic flume and its mould. In my design, UG is used as a modeling tool. Without sketch, UG can set up the model at your will to improve the modeling accuracy and speed the modeling. The flume’s design includes the selection of the material, thickness, contractibility and how to use UG to plot it. The mould’s design includes the selection of the cavity’ number, the cavity’ fractal face and moulding system; in addition, this design includes the designs of injecting mould’ accessory and other parts. Especially, in the selection of the cavity’ number, I adopt the plan of four cavities in a mould in order to make the charge least.

Key words: mould ¨ UG system; plastic flume; mould for plastics; mould’ design

目 录

0 引言 ……………………………………………………………… 1

1 水槽及其注塑模具设计总体方案……………………………………… 3

1.1 总体方案论证 ………………………………………………………… 3

2 水槽设计部分 ………………………………………………………… 4

2.1 UG软件设计部分 ………………………………………………… 4

2.2 塑料水槽的参数设定 ………………………………………………… 6

3 水槽模具设计部分 …………………………………………………… 11

3.1 确定型腔数目 ………………………………………………………… 11

3.2 型腔分型面及浇注系统 ……………………………………………… 14

3.3 注射成型模具零部件的设计 ………………………………………… 16

3.4 其它辅助结构件 …………………………………………………… 21

3.5 脱模机构 ……………………………………………………………… 22

3.6 复位机构 ……………………………………………………………… 22

3.7 预期结果 ……………………………………………………………… 22

4 结论 …………………………………………………………………… 23

致谢 ………………………………………………………………………… 24

参考文献 …………………………………………………………………… 25