设计简介

摘 要

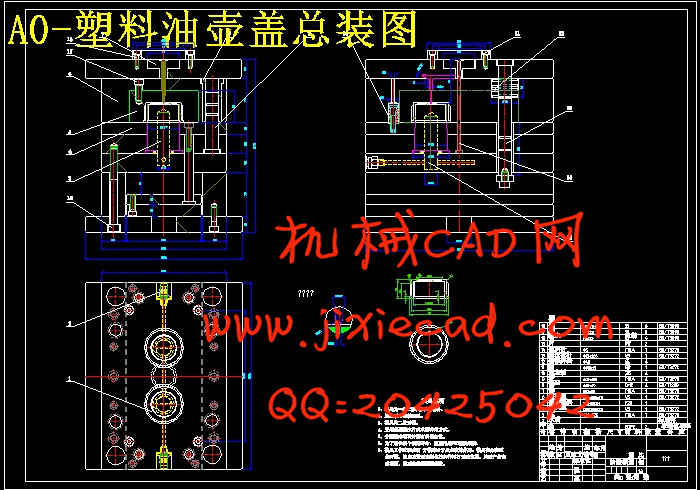

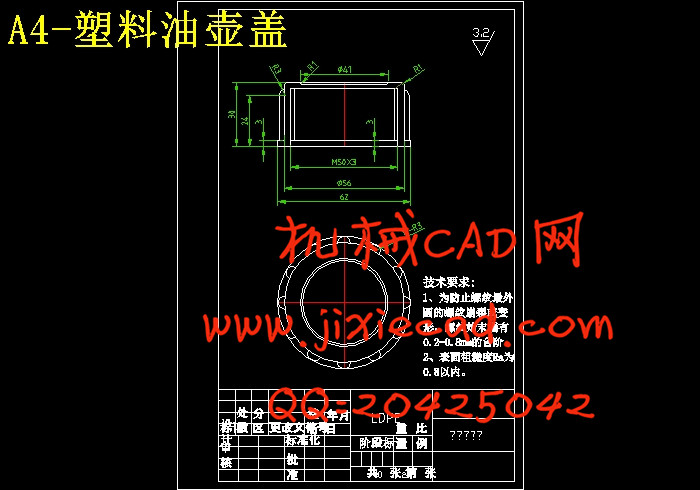

随着现代社会的发展,模具行业也发展越来越快,模具加工精度,模具的应用范围都越来越广,因此模具在社会发展中的作用和地位也越来越大,越来越高。塑料注射模具是成型塑料制件的一种重要工艺装备,在塑料制品的生产中起着关键作用,在生产实践中得到了较为广泛的应用。本次毕业设计以塑料油壶盖为例,通过对塑件进行制品分析及材料工艺性,初选了注射机的型号与规格,确定塑件注射工艺参数,设计注射模的结构等这一过程,讲述了模具的设计过程与设计方法。通过这一过程,不但了解和掌握塑料模具设计的基本原则、方法,而且能较为熟练的使用计算机CAD绘图软件,为今后从事设计工作打下坚实的基础。

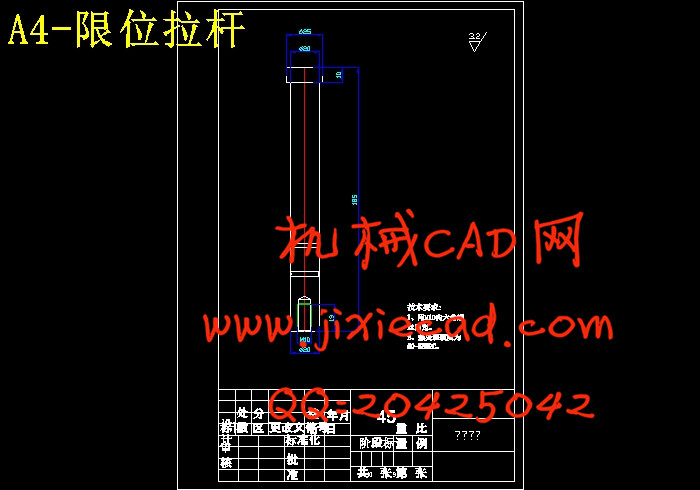

关键词:塑料油壶盖模具 二次开模 拉料杆 螺纹强脱 试模

Abstract

随着现代社会的发展,模具行业也发展越来越快,模具加工精度,模具的应用范围都越来越广,因此模具在社会发展中的作用和地位也越来越大,越来越高。塑料注射模具是成型塑料制件的一种重要工艺装备,在塑料制品的生产中起着关键作用,在生产实践中得到了较为广泛的应用。本次毕业设计以塑料油壶盖为例,通过对塑件进行制品分析及材料工艺性,初选了注射机的型号与规格,确定塑件注射工艺参数,设计注射模的结构等这一过程,讲述了模具的设计过程与设计方法。通过这一过程,不但了解和掌握塑料模具设计的基本原则、方法,而且能较为熟练的使用计算机CAD绘图软件,为今后从事设计工作打下坚实的基础。

关键词:塑料油壶盖模具 二次开模 拉料杆 螺纹强脱 试模

Abstract

With the development of modern society, the mold industry has developed more and more fast, precision mold, mold application range are more and more widely, and the status of the mold in the social development in the role is also growing, more and more high. The plastic injection mold is an important tooling molding plastic articles, plays a key role in the production of plastic products, has been widely used in production practice. The graduation design in plastic pot cover as the example, through the process of product analysis and material of plastic parts, primary models and specifications of the injection machine, determine the injection molding process parameters, the process design of the injection mold structure, describes the design process and design of mould method. Through this process, not only to understand and master the basic principles, methods of plastic mold design, but also can use the computer CAD drawing software more skilled, engaged in design work for the future and lay a solid foundation.

Keywords: Plastic oiler cover mold the two opening pulling rod strong screw removal test mode

目 录

绪 论........................................................................1Keywords: Plastic oiler cover mold the two opening pulling rod strong screw removal test mode

目 录

第一章 塑件分析.............................................................4

1.1塑件结构材料分析.........................................................4

1.2 塑件材料分析.............................................................5

1.3 塑件成型工艺分析.........................................................6

第二章 初选注射机的型号和规格..............................................8

2.1注射机概要................................................................8

2.2注射机分类................................................................8

2.3注射机选择................................................................8

第三章 塑件注射工艺参数的确定............................................10

3.1塑件的结构工艺性.........................................................10

3.1.1塑件的尺寸精度分析...................................................10

3.1.2塑件表面质量分析.....................................................10

3.1.3塑件的结构工艺性分析.................................................10

3.2塑件的生产批量...........................................................11

3.3有关计算分析.............................................................11

3.3.1计算塑件体积和质量...................................................11

3.3.2确定型腔数量.........................................................11

3.3.3确定注射成型的工艺参数...............................................11

第四章 注射模的结构设计..................................................13

4.1 确定分型面..............................................................13

4.2确定浇注系统............................................................13

4.2.1浇注系统设计要点...................................................13

4.2.2主流道设计..........................................................14

4.2.3分流道设计..........................................................14

4.2.4点浇口设计料穴设计.................................................15

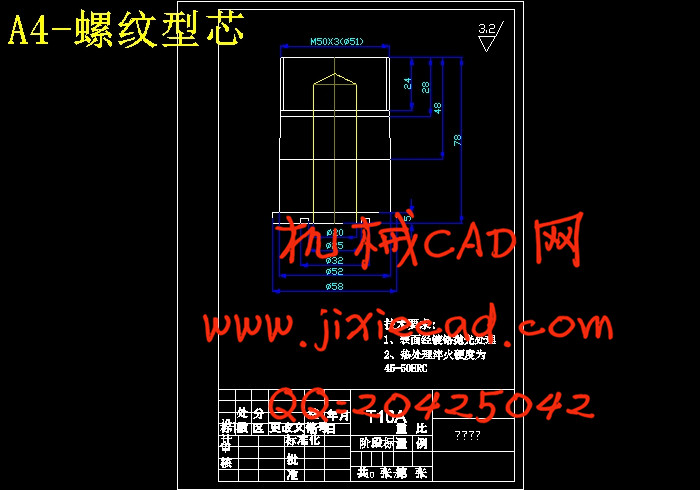

4.3确定型腔、型芯的结构及固定方式.......................................17

4.3.1型腔、型芯的结构设计...............................................17

4.3.2固定方式............................................................19

4.4型腔和型芯的工作尺寸计算..............................................19

4.4.1型腔尺寸计算........................................................19

4.4.2固定方式............................................................20

4.5型腔壁厚和底板厚度计算................................................20

4.5.1模具型腔壁厚的确定.................................................20

4.5.2动模垫板厚度理论计算公式..........................................20

4.5.3模具型腔模板总体尺寸的确定........................................21

4.6螺纹脱出方式的设计.....................................................21

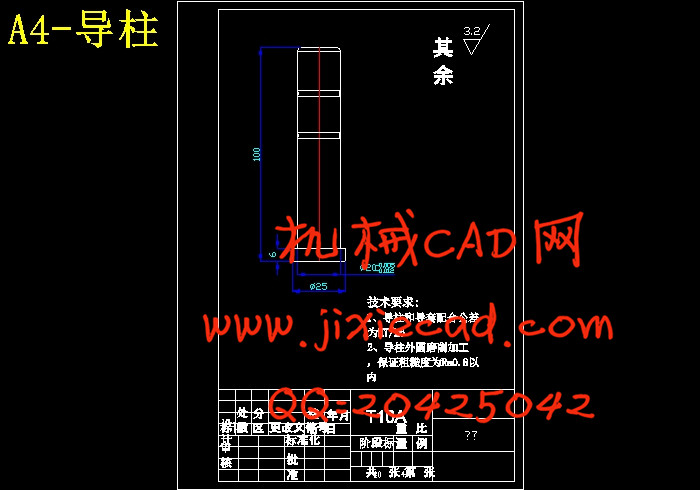

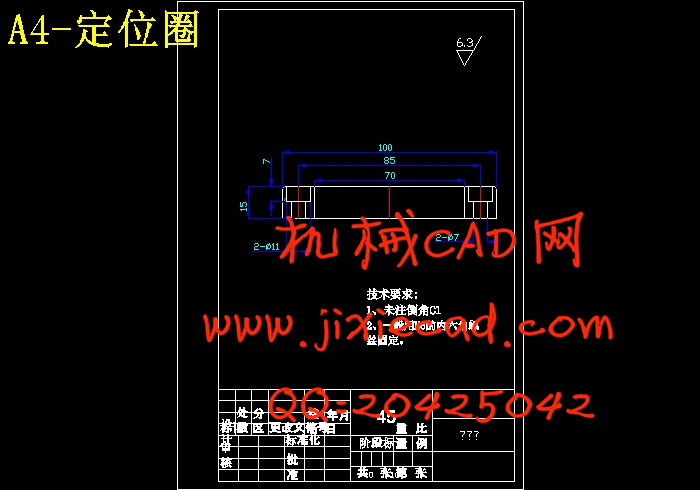

4.7确定模具的导向机构.....................................................22

4.8冷却方式................................................................25

第五章 注射机有关设计的校核..............................................26

5.1模具闭合高度的确定......................................................26

5.2模具闭合高度的校核................................................... 26

5.3模具安装部分的校核.....................................................26

5.4模具开模行程的校核.....................................................26

5.5注射量的校核............................................................26

第六章 模具装配和试模..............................................28

结 论..............................................................32

参考文献............................................................33

致 谢.…....................................................................34