设计简介

摘要

本课题的研究目的:检验理论知识掌握情况,将理论与实践结合;逐步掌握进行模具设计的方法、过程,为将来走向工作岗位进行科技开发工作和撰写科研论文打下基础;培养自己的动手能力、创新能力、计算机运用能力。

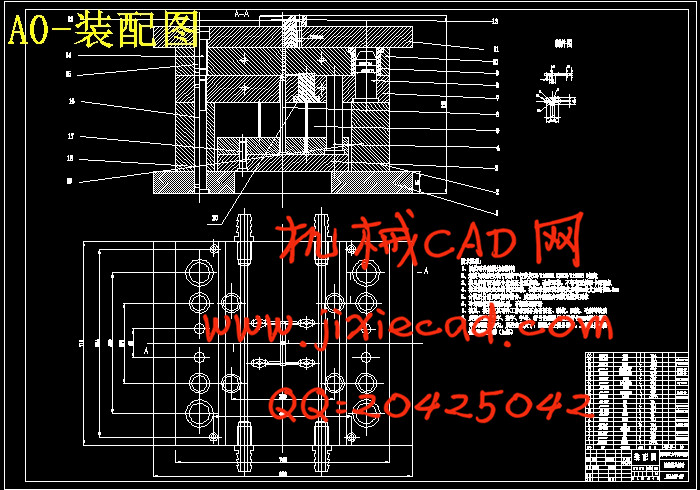

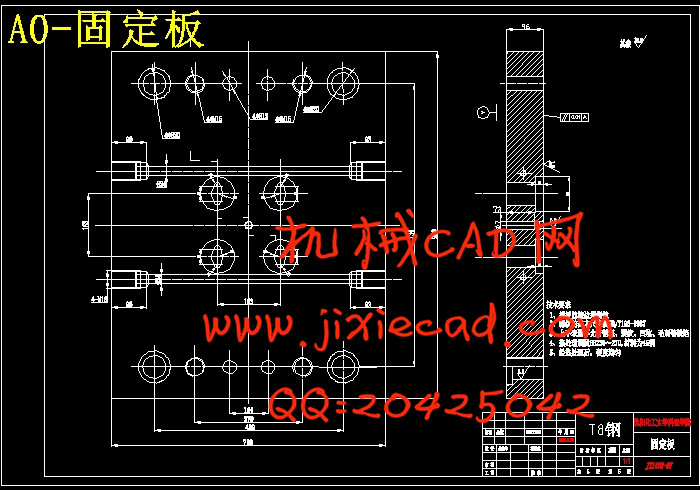

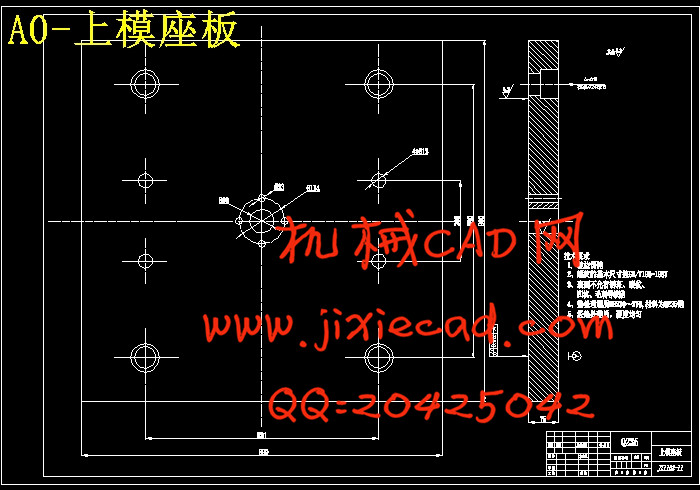

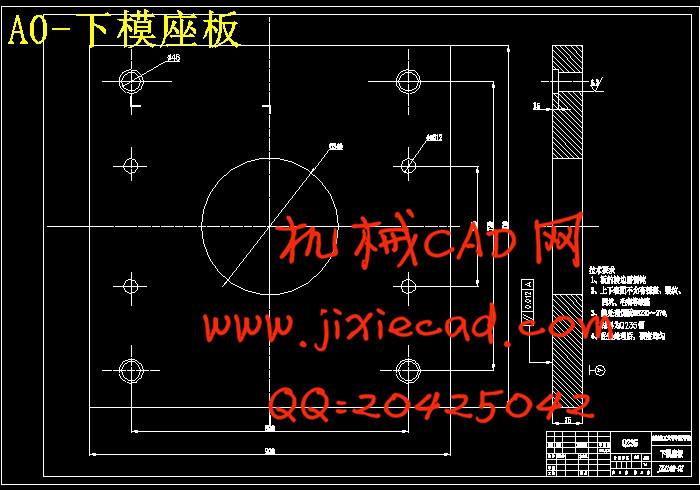

论文根据工程实际的需要完成锁盖的注射模设计。在设计中采用塑料注射成型论文中具体分析了产品的工艺性,确定了所采用塑料的工艺参数和所采用的成型设备,确定了模具制作的总体方案,分析并解决了模具的总体结构和各工作部分的具体结构,并进行了一些必要的尺寸计算和强度的校核。论文中还对分型面、浇注系统、脱模机构和温度调节系统进行了分析设计,完成了工件工程图设计,圆满完成了模具设计所要求的各项工作。

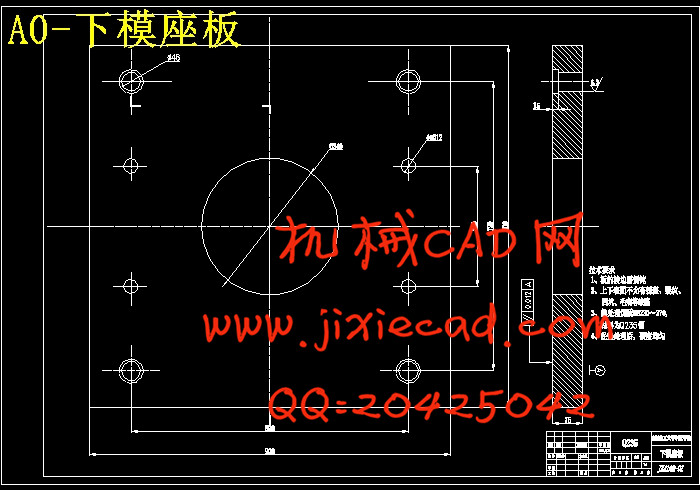

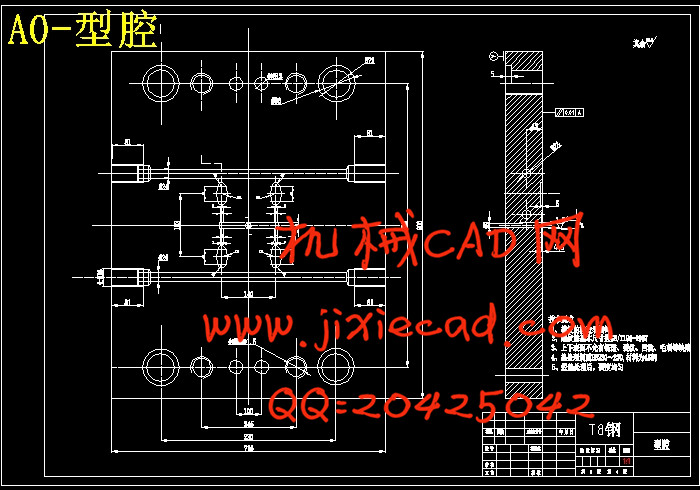

本文中针对锁盖注射模具制定出合理的设计结构,其中包括成型部分及其零部件设计,浇注系统设计,脱模机构设计,冷却系统设计等。根据分析,设计了一套塑料注射模具,并对模具以及主要零件进行了CAD绘图。

模具工业是国民经济的基础工业,被称为“工业之母”。在塑料制品生产过程中,模具的设计是相当重要的一环;因为模具的好坏直接影响到塑件质量,以及价格的高低。所以作为一名模具设计者,应该具备以下基本要求:模具的结构基本合理;能够实现塑件的自动脱模;在此基础上尽可能优化结构,降低优化结构和成本。

国内的发展情况;目前国内模具行业的基本情况是,随着轻工业及汽车制造业的迅发展,模具设计制造日渐受到人们广泛关注,已形成一个行业。目前存在的主要问题是:目前虽然我国从事塑料设计的人员不少,但大多专业知识不够丰富,没有受过系统专门系统的训练,所以高水平的设计人员不多;专业书籍缺乏,没有一套我国自己的设计理论与设计数据,大多数模具设计者都是依靠自己的设计经验来设计新的模具,知识更新很慢;从设计结构上看,我们的设计还不够细致,许多细节考虑的欠周到,以至于模具使用受命不长,特别是冷却系统和热流道技术,在这方面与国外的差距更大;从加工工艺水平看,主要是设备水平不高,专门设备使用的少,加工出来的模具表面精度很难达到国外水平,检测手段落后,模具装配水平不高,导致容易出现溢料或错位现象。

国外的模具发展状况具体表现特征:集成化技术,现代模具设计制造系统不仅应强调信息的集成,更应该强调技术人和管理的集成。在开发模式制造系统时强调“多集成”的概念,即信息集成、智能集成、串并行工作机制集成及人员集成,这更适合未来制造系统的需要。

关键词:注射模具; 浇注系统; 脱模机构; 冷却系统

Abstract

This topic research purpose: to test the theoretical knowledge to grasp the situation, the combination of theory and practice; gradually master the method and process of mold design, is the future direction of job of science and technology development and write a scientific paper base; culture their practical ability, innovation ability, the computer skills.

The design of the injection mold for the lock is completed according to the actual need of the project.. In the design of a plastic injection molding the specific analysis of the products of the process, identified the plastics processing parameters and the molding equipment, to determine the overall scheme of mould making, to analyze and solve the general structure of the die and the working part of the concrete structure, and make the necessary size calculation and strength check. The paper also parting surface, gating system, demoulding mechanism and temperature regulation system for the analysis and design, completed the design of engineering drawing workpiece, the successful completion of the work required by the die design.

In this paper, a reasonable design structure for the injection mold of the lock cover is made, including the design of the molding part and its parts, gating system design, the design of the mould release mechanism, cooling system design, etc.. According to the analysis, a set of plastic injection mould is designed, and the CAD drawing of the die and the main parts is designed.

Die industry is the basic industry of the national economy, known as the mother of industry ". In the production process of plastic products, the design of the die is a very important one. Because the mold directly affects the quality of plastic parts, and the price level.. So as a mold designer, should have the following basic requirements: the mold structure of the basic and reasonable; can realize the automatic stripping of plastic parts; on this basis, as far as possible to optimize the structure and reduce the cost structure and optimization.

Domestic development; is the basic situation of domestic mold industry, along with the fast development of the light industry and automobile manufacturing, mold design and manufacturing increasingly people's extensive concern, and has formed an industry.The main problems are: Although many of our staff engaged in plastic design, but most professional knowledge is not rich enough, no special training system is a system, so not many high level designers; lack of professional books, not a set of our own design theory and design of data, most of the mold designers is to design a new mold design rely on their own experience, knowledge update slowly; from the point of structure design, our design is not detailed enough, many of the details considered less thoughtful, so that the mould service life is not long, especially in cooling system and hot runner technology, the greater the gap with foreign countries; from the processing level, is the main equipment level is not high, the use of specialized equipment, precision mold surface processing is hard to reach the level of foreign countries, detection means backward, the mold assembly level is not high, prone to cause overflow or dislocation.

The specific features of the development of the mold abroad are: integrated technology, modern die design and manufacturing system should not only emphasize the integration of information, but also emphasize the integration of technology and management.. In the development of mode manufacturing system, the concept of multi integration is emphasized, that is, the integration of information, intelligence and the mechanism of the serial parallel operation and the integration of personnel, which is more suitable for the future manufacturing system.

Keywords:injection mould; gating system; mould release mechanism; cooling system

目 录

第一章引言…………………………………………………1

第二章塑件的工艺分析 ……………………………………2

2.1 塑件的工艺性分析………………………………………2

2.2 塑件的结构和尺寸精度…………………………………3

2.3 计算塑件的体积和质量…………………………………4

2.4 注射机的初选……………………………………………4

第三章分型面选择和浇注系统设计………………………6

3.1 注射分行面的选择………………………………………6

3.2 浇注系统的设计…………………………………………7

第四章成型零件的设计……………………………………12

4.1 模具型腔的设计结构……………………………………12

4.2 型芯的结构设计…………………………………………13

4.3 成型零件的尺寸确定……………………………………13

4.4 标准模架选用……………………………………………15

4.5 成型型腔壁厚校检………………………………………17

第五章顶出机构的设计……………………………………19

5.1 顶出机构的分类…………………………………………19

5.2 顶出机构的结构组成……………………………………19

5.3 结构分类…………………………………………………19

5.4 结构设计要求……………………………………………19

5.5 结构设计…………………………………………………19

5.6 顶出机构的设计原理……………………………………20

第六章冷却系统的设计……………………………………22

6.1 冷却系统设计……………………………………………22

6.2 冷却系统计算……………………………………………22

6.3 冷却时间确定……………………………………………23

6.4 冷却系统设计原则………………………………………23

6.5 冷却系统的结构形式……………………………………24

第七章 排气系统……………………………………………25

第八章成型设备有关参数校核……………………………26

8.1 注射压力校核……………………………………………26

8.2 锁模力校核………………………………………………26

8.3 开模行程校核……………………………………………26

第九章模具特点和工作原理………………………………28

9.1 模具的特点………………………………………………28

9.2 模具的工作过程…………………………………………28

结论……………………………………………………………29

参考文献………………………………………………………30

致谢……………………………………………………………31

本课题的研究目的:检验理论知识掌握情况,将理论与实践结合;逐步掌握进行模具设计的方法、过程,为将来走向工作岗位进行科技开发工作和撰写科研论文打下基础;培养自己的动手能力、创新能力、计算机运用能力。

论文根据工程实际的需要完成锁盖的注射模设计。在设计中采用塑料注射成型论文中具体分析了产品的工艺性,确定了所采用塑料的工艺参数和所采用的成型设备,确定了模具制作的总体方案,分析并解决了模具的总体结构和各工作部分的具体结构,并进行了一些必要的尺寸计算和强度的校核。论文中还对分型面、浇注系统、脱模机构和温度调节系统进行了分析设计,完成了工件工程图设计,圆满完成了模具设计所要求的各项工作。

本文中针对锁盖注射模具制定出合理的设计结构,其中包括成型部分及其零部件设计,浇注系统设计,脱模机构设计,冷却系统设计等。根据分析,设计了一套塑料注射模具,并对模具以及主要零件进行了CAD绘图。

模具工业是国民经济的基础工业,被称为“工业之母”。在塑料制品生产过程中,模具的设计是相当重要的一环;因为模具的好坏直接影响到塑件质量,以及价格的高低。所以作为一名模具设计者,应该具备以下基本要求:模具的结构基本合理;能够实现塑件的自动脱模;在此基础上尽可能优化结构,降低优化结构和成本。

国内的发展情况;目前国内模具行业的基本情况是,随着轻工业及汽车制造业的迅发展,模具设计制造日渐受到人们广泛关注,已形成一个行业。目前存在的主要问题是:目前虽然我国从事塑料设计的人员不少,但大多专业知识不够丰富,没有受过系统专门系统的训练,所以高水平的设计人员不多;专业书籍缺乏,没有一套我国自己的设计理论与设计数据,大多数模具设计者都是依靠自己的设计经验来设计新的模具,知识更新很慢;从设计结构上看,我们的设计还不够细致,许多细节考虑的欠周到,以至于模具使用受命不长,特别是冷却系统和热流道技术,在这方面与国外的差距更大;从加工工艺水平看,主要是设备水平不高,专门设备使用的少,加工出来的模具表面精度很难达到国外水平,检测手段落后,模具装配水平不高,导致容易出现溢料或错位现象。

国外的模具发展状况具体表现特征:集成化技术,现代模具设计制造系统不仅应强调信息的集成,更应该强调技术人和管理的集成。在开发模式制造系统时强调“多集成”的概念,即信息集成、智能集成、串并行工作机制集成及人员集成,这更适合未来制造系统的需要。

关键词:注射模具; 浇注系统; 脱模机构; 冷却系统

Abstract

This topic research purpose: to test the theoretical knowledge to grasp the situation, the combination of theory and practice; gradually master the method and process of mold design, is the future direction of job of science and technology development and write a scientific paper base; culture their practical ability, innovation ability, the computer skills.

The design of the injection mold for the lock is completed according to the actual need of the project.. In the design of a plastic injection molding the specific analysis of the products of the process, identified the plastics processing parameters and the molding equipment, to determine the overall scheme of mould making, to analyze and solve the general structure of the die and the working part of the concrete structure, and make the necessary size calculation and strength check. The paper also parting surface, gating system, demoulding mechanism and temperature regulation system for the analysis and design, completed the design of engineering drawing workpiece, the successful completion of the work required by the die design.

In this paper, a reasonable design structure for the injection mold of the lock cover is made, including the design of the molding part and its parts, gating system design, the design of the mould release mechanism, cooling system design, etc.. According to the analysis, a set of plastic injection mould is designed, and the CAD drawing of the die and the main parts is designed.

Die industry is the basic industry of the national economy, known as the mother of industry ". In the production process of plastic products, the design of the die is a very important one. Because the mold directly affects the quality of plastic parts, and the price level.. So as a mold designer, should have the following basic requirements: the mold structure of the basic and reasonable; can realize the automatic stripping of plastic parts; on this basis, as far as possible to optimize the structure and reduce the cost structure and optimization.

Domestic development; is the basic situation of domestic mold industry, along with the fast development of the light industry and automobile manufacturing, mold design and manufacturing increasingly people's extensive concern, and has formed an industry.The main problems are: Although many of our staff engaged in plastic design, but most professional knowledge is not rich enough, no special training system is a system, so not many high level designers; lack of professional books, not a set of our own design theory and design of data, most of the mold designers is to design a new mold design rely on their own experience, knowledge update slowly; from the point of structure design, our design is not detailed enough, many of the details considered less thoughtful, so that the mould service life is not long, especially in cooling system and hot runner technology, the greater the gap with foreign countries; from the processing level, is the main equipment level is not high, the use of specialized equipment, precision mold surface processing is hard to reach the level of foreign countries, detection means backward, the mold assembly level is not high, prone to cause overflow or dislocation.

The specific features of the development of the mold abroad are: integrated technology, modern die design and manufacturing system should not only emphasize the integration of information, but also emphasize the integration of technology and management.. In the development of mode manufacturing system, the concept of multi integration is emphasized, that is, the integration of information, intelligence and the mechanism of the serial parallel operation and the integration of personnel, which is more suitable for the future manufacturing system.

Keywords:injection mould; gating system; mould release mechanism; cooling system

目 录

第一章引言…………………………………………………1

第二章塑件的工艺分析 ……………………………………2

2.1 塑件的工艺性分析………………………………………2

2.2 塑件的结构和尺寸精度…………………………………3

2.3 计算塑件的体积和质量…………………………………4

2.4 注射机的初选……………………………………………4

第三章分型面选择和浇注系统设计………………………6

3.1 注射分行面的选择………………………………………6

3.2 浇注系统的设计…………………………………………7

第四章成型零件的设计……………………………………12

4.1 模具型腔的设计结构……………………………………12

4.2 型芯的结构设计…………………………………………13

4.3 成型零件的尺寸确定……………………………………13

4.4 标准模架选用……………………………………………15

4.5 成型型腔壁厚校检………………………………………17

第五章顶出机构的设计……………………………………19

5.1 顶出机构的分类…………………………………………19

5.2 顶出机构的结构组成……………………………………19

5.3 结构分类…………………………………………………19

5.4 结构设计要求……………………………………………19

5.5 结构设计…………………………………………………19

5.6 顶出机构的设计原理……………………………………20

第六章冷却系统的设计……………………………………22

6.1 冷却系统设计……………………………………………22

6.2 冷却系统计算……………………………………………22

6.3 冷却时间确定……………………………………………23

6.4 冷却系统设计原则………………………………………23

6.5 冷却系统的结构形式……………………………………24

第七章 排气系统……………………………………………25

第八章成型设备有关参数校核……………………………26

8.1 注射压力校核……………………………………………26

8.2 锁模力校核………………………………………………26

8.3 开模行程校核……………………………………………26

第九章模具特点和工作原理………………………………28

9.1 模具的特点………………………………………………28

9.2 模具的工作过程…………………………………………28

结论……………………………………………………………29

参考文献………………………………………………………30

致谢……………………………………………………………31