设计简介

探测器后盖模具设计及其型腔仿真加工

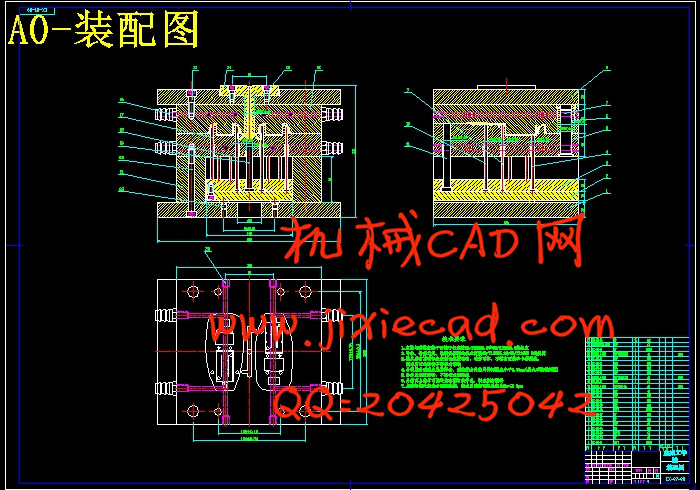

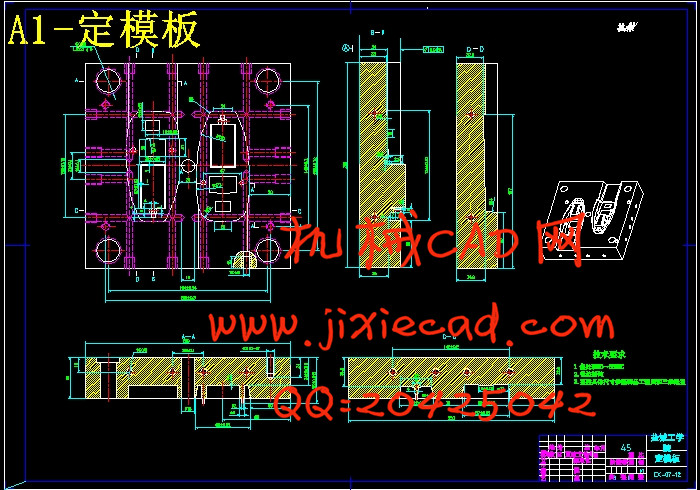

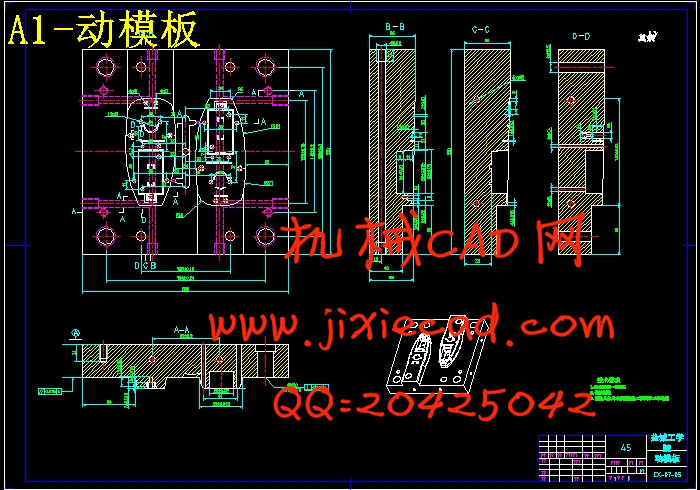

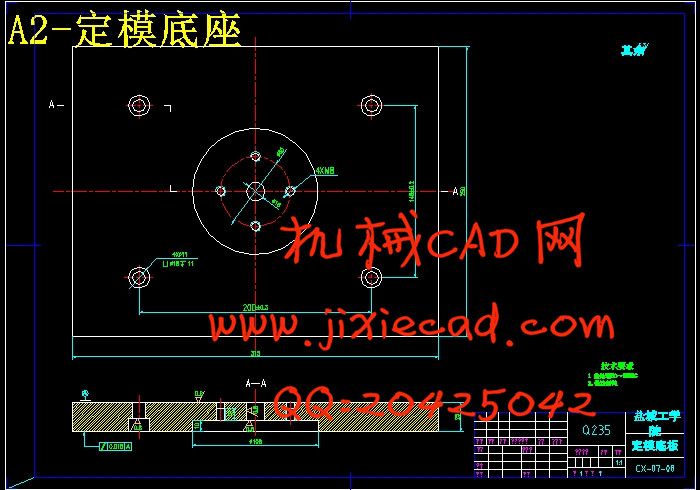

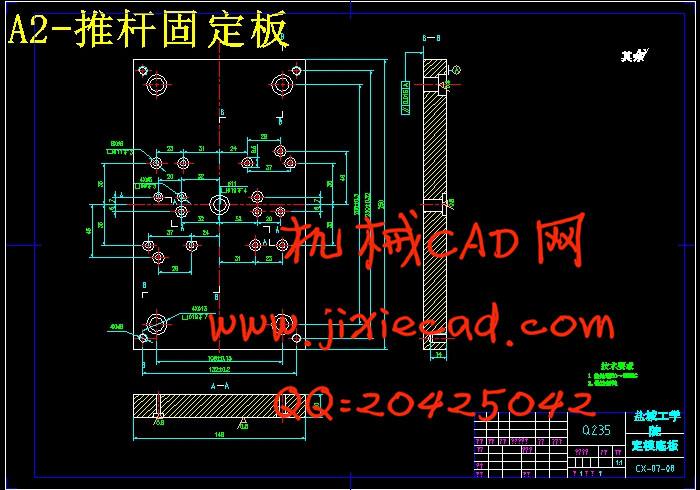

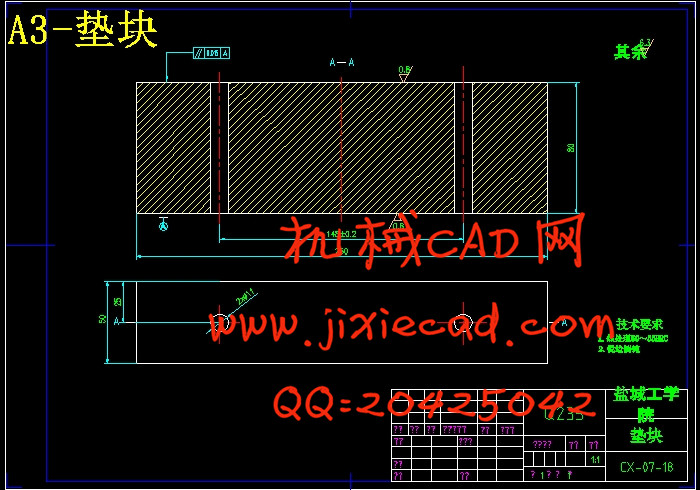

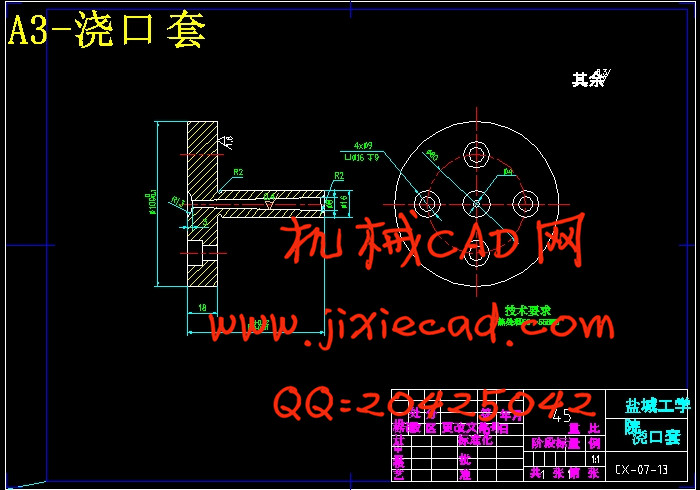

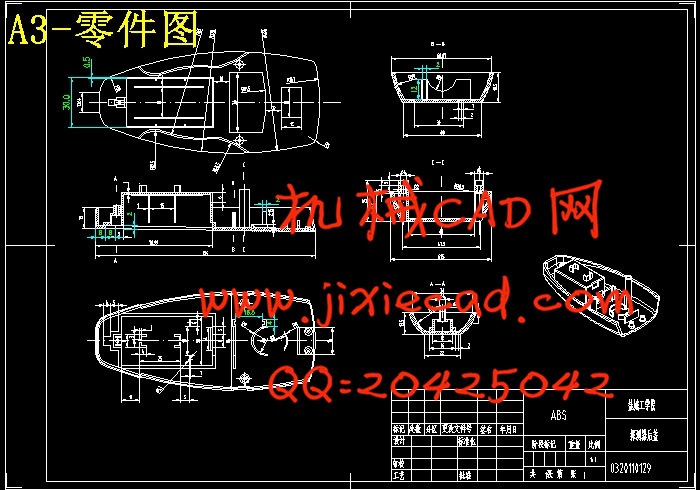

摘要: 本课题来源于盐城科城电子有限公司,任务是探测器后盖模具设计。针对探测器制品表面光滑度要高问题, 分析了探测器制品的工艺特性, 设计潜伏式浇口。通过制品质量计算选择了注塑机(SZ-100/60型), 并且通过对零件的工艺分析确定型腔数量、选挥分型面、设计型芯和型腔,由于设计的零件属于中小型所以采用了一模二腔的注塑形式。本模具选用的是标准的模架,并对动、定模之间的导向和定位、工件推出机构、浇注系统的总体布置方案、垫块的尺寸、推出导向机构、复位机构进行了设计,并且对组成模具型腔的各个部分进行了计算,对所选的注塑机的各个参数进行了校核。模具推出机构采用的是顶杆推出 ,根据制品形状对顶杆进行了特殊设计。制品形状的特殊性在加工方面采用了电脉冲加工。本模具结构紧凑, 工作可靠, 成型工件满足质量要求,较好地实现了设计要求。

关键词:注塑模;分型面;探测器;仿真加工

The Mold design of backsheell of detector and the processing simulation of the cavity

Abstract:The subjects come from the Yancheng City Branch Electronics Co., Ltd,Backshell detector Mold Design . To improveNote pieces detectorSurface quality and processing efficiency ,Reduce processing costs,Note against detector surface to a high degree of smoothness problem ,Note analysis of the detector characteristics of the technology,Latent-gate design。Through quality productsCalculation chose injection molding machine(SZ-100/60Types), And parts of the Process AnalysisDetermine the number of cavity, Play election-surfaces Design-core and cavity . Because I want to belong to the design of partsTherefore, the use of a two-cavity injection form . The die is the choiceStandard moldbase , Also dynamic, Modeling between the orientation and positioning , Workpiece Launch, Gating system the overall layout program , Pad size, Launched oriented institutions, Reduction and the design agencies , And the mold cavity composed of the various parts of the calculation , Injection of the selected machines in all parameters of the Check . Die Launch is the launch mandril, According to shape products to push for a special design . The special shape products processing used electrical pulse processing. The compact structure Die, Reliable, Forming workpiece meet quality requirements , Achieve better design requirements.

Keywords :Injection; Plane division; Cavity

The Mold design of backsheell of detector and the processing simulation of the cavity

目 录

1 前 言 1

2 模具总体设计 3

2.1 制品的分析 3

2.2模具总体方案设计 4

2.3注射机的选择 4

2.4型腔数的确定 5

2.5型腔的布局 5

2.6分型面的确定 6

2.7浇注系统设计 6

2.7.1浇口的形式 7

2.7.2流道、主流道衬套及定位环的设计 7

2.7.3冷料井的设计 8

2.8冷却系统的设计 9

2.9模架的选择 11

2.10导柱、导套的选择 12

2.10.1导柱的选择 12

2.10.2导套的选择 13

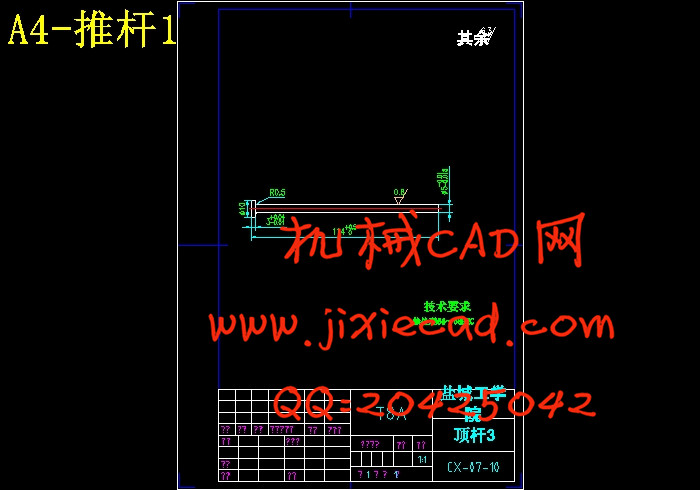

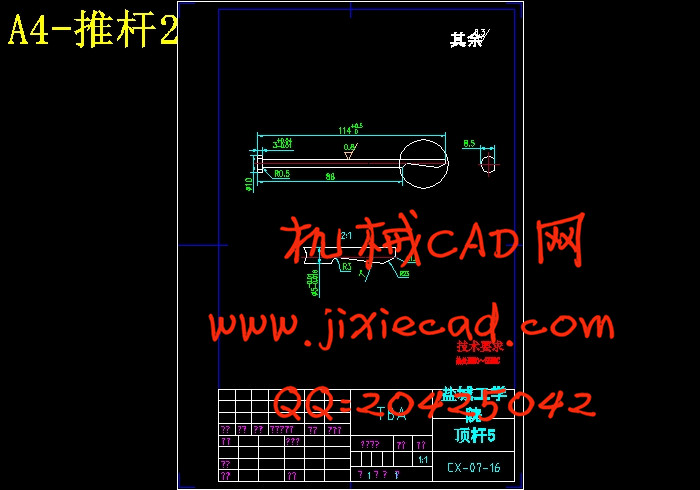

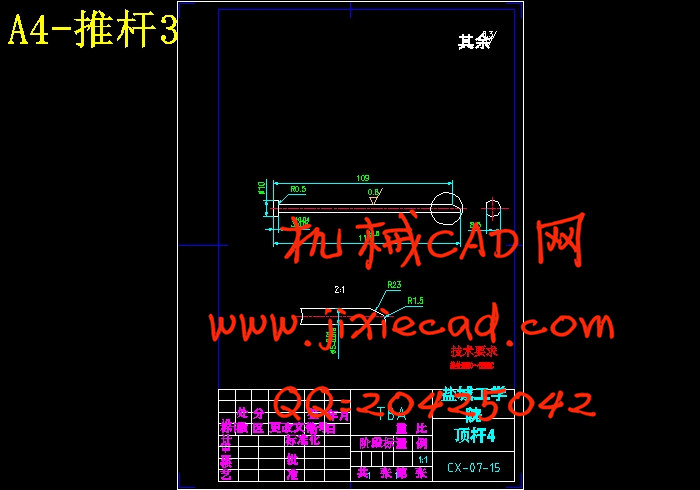

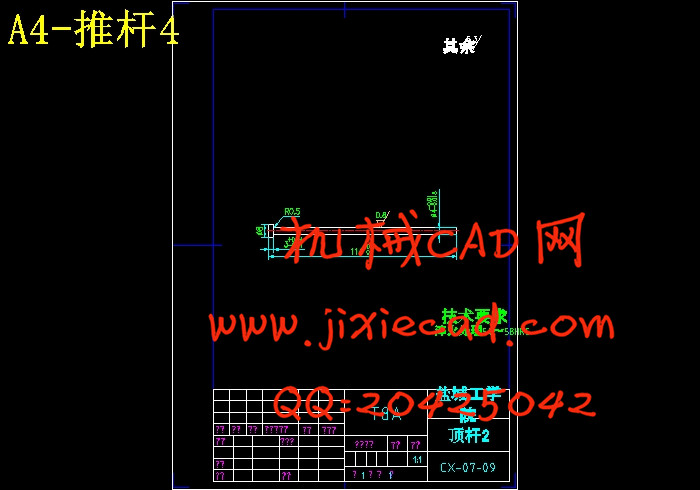

2.11顶杆设计 13

2.12复位杆 14

2.13锁模力校核 14

2.14开模行程的校核 15

3工艺分析及仿真加工 16

3.1模具的注塑工艺分析 16

3.2模具成型件制造工艺与加工工序 17

3.3数控仿真 18

4结论 22

参考文献 23

致谢 24

摘要: 本课题来源于盐城科城电子有限公司,任务是探测器后盖模具设计。针对探测器制品表面光滑度要高问题, 分析了探测器制品的工艺特性, 设计潜伏式浇口。通过制品质量计算选择了注塑机(SZ-100/60型), 并且通过对零件的工艺分析确定型腔数量、选挥分型面、设计型芯和型腔,由于设计的零件属于中小型所以采用了一模二腔的注塑形式。本模具选用的是标准的模架,并对动、定模之间的导向和定位、工件推出机构、浇注系统的总体布置方案、垫块的尺寸、推出导向机构、复位机构进行了设计,并且对组成模具型腔的各个部分进行了计算,对所选的注塑机的各个参数进行了校核。模具推出机构采用的是顶杆推出 ,根据制品形状对顶杆进行了特殊设计。制品形状的特殊性在加工方面采用了电脉冲加工。本模具结构紧凑, 工作可靠, 成型工件满足质量要求,较好地实现了设计要求。

关键词:注塑模;分型面;探测器;仿真加工

The Mold design of backsheell of detector and the processing simulation of the cavity

Abstract:The subjects come from the Yancheng City Branch Electronics Co., Ltd,Backshell detector Mold Design . To improveNote pieces detectorSurface quality and processing efficiency ,Reduce processing costs,Note against detector surface to a high degree of smoothness problem ,Note analysis of the detector characteristics of the technology,Latent-gate design。Through quality productsCalculation chose injection molding machine(SZ-100/60Types), And parts of the Process AnalysisDetermine the number of cavity, Play election-surfaces Design-core and cavity . Because I want to belong to the design of partsTherefore, the use of a two-cavity injection form . The die is the choiceStandard moldbase , Also dynamic, Modeling between the orientation and positioning , Workpiece Launch, Gating system the overall layout program , Pad size, Launched oriented institutions, Reduction and the design agencies , And the mold cavity composed of the various parts of the calculation , Injection of the selected machines in all parameters of the Check . Die Launch is the launch mandril, According to shape products to push for a special design . The special shape products processing used electrical pulse processing. The compact structure Die, Reliable, Forming workpiece meet quality requirements , Achieve better design requirements.

Keywords :Injection; Plane division; Cavity

The Mold design of backsheell of detector and the processing simulation of the cavity

目 录

1 前 言 1

2 模具总体设计 3

2.1 制品的分析 3

2.2模具总体方案设计 4

2.3注射机的选择 4

2.4型腔数的确定 5

2.5型腔的布局 5

2.6分型面的确定 6

2.7浇注系统设计 6

2.7.1浇口的形式 7

2.7.2流道、主流道衬套及定位环的设计 7

2.7.3冷料井的设计 8

2.8冷却系统的设计 9

2.9模架的选择 11

2.10导柱、导套的选择 12

2.10.1导柱的选择 12

2.10.2导套的选择 13

2.11顶杆设计 13

2.12复位杆 14

2.13锁模力校核 14

2.14开模行程的校核 15

3工艺分析及仿真加工 16

3.1模具的注塑工艺分析 16

3.2模具成型件制造工艺与加工工序 17

3.3数控仿真 18

4结论 22

参考文献 23

致谢 24