设计简介

(套筒注塑模)

摘要

分析了PA1010塑料的特性及其对注塑工艺的影响,介绍了套筒注塑模主要零部件的尺寸计算方法,注塑模结构及工作过程。根据套筒零件的特点确定了注塑模结构,并且模具结构设计精巧,达到了塑件的尺寸精度。

针对塑件脱模过程中的难点,设计了一种非常规抽芯的注塑模结构,并对模具设计与制造中的一些关键问题加以详述。由于该模具需要3个方向抽芯,因此选择了多种侧向分型机构,并对其中之一作了重点介绍,同时对浇注系统,顶出机构也作了简要说明。

实践证明,该模具设计合理,动作可靠,对同类塑件的注塑模设计有一定的参考价值。

关键词:PA1010塑料 ;注塑模 ;设计 ;套筒 ;抽芯机构;侧向抽芯。

(Design of the Cylindrical bush Injection Mould)

Abstract

The properties of the PA1010 plastics and their influences to the moulding technology are analyzed. The structure and working process of the cylindrical bush injection mould are introduced.And the dimension calculations for some key components of the mould are stated.Thestructure of the injection mould for the cylindrical bush has been determined according to it’s characteristics . The design of the mould structure is smart and the operation of the mould is easy. The plastic parts moulded with the mould have reached the required dimension precision .

According to the difficulty in the plastic part demoulding process ,an injection mould with non-tradional core-pulling mechanism has been designed. And some key points in design and manufacture of the mould are stated in detail. Since the mould requires core-pulling on three directions ,various side parting mechanisms have been used and one of them is mainly introduced .The feed system and the ejector mechanism are briefly introduced .

Practices show that the mould are design is reasonable and the mould movement is reliable. It can serve as a reference to the design of the moulds for similar parts.

Key words:PA1010plastic;injection mould; design;

Cylindrical bush;core-pulling;side parting.

绪论----------------------------------------------1

第1章 模塑工艺规程的编制-----------------------5

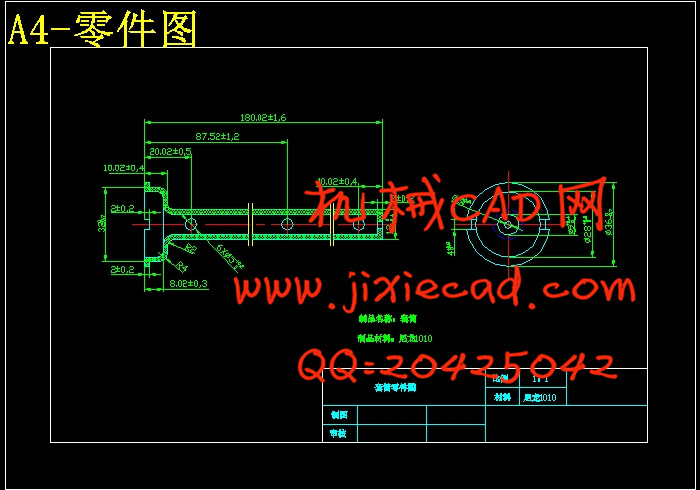

1.1塑件的工艺性分析--------------------------5

1.2计算塑件体积和质量------------------------7

1.3塑件注塑工艺参数的确定--------------------8

第2章 注塑模的机构设计--------------------------9

2.1分型面的选择------------------------------ 9

2.2确定型腔的排列方式------------------------10

2.3浇注系统设计 -----------------------------11

2.4抽芯机构设计 -----------------------------13

2.5推出机构设计 -----------------------------15

2.6合模导向机构设计------------------------- 16

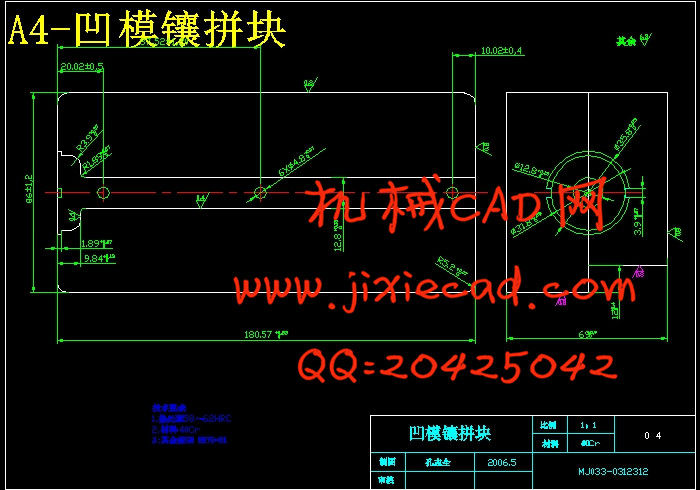

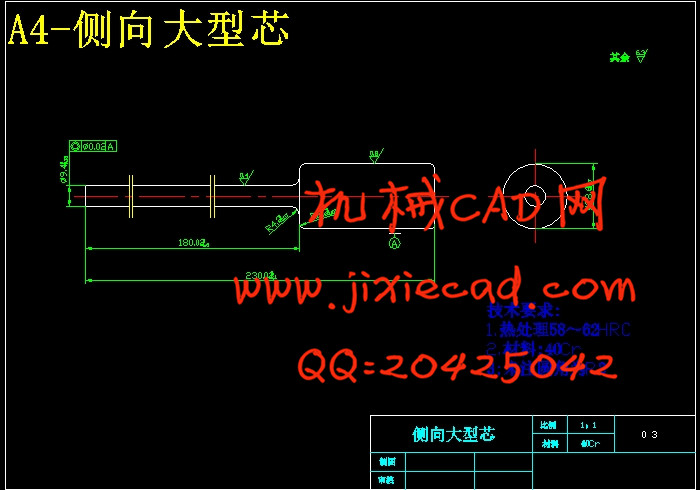

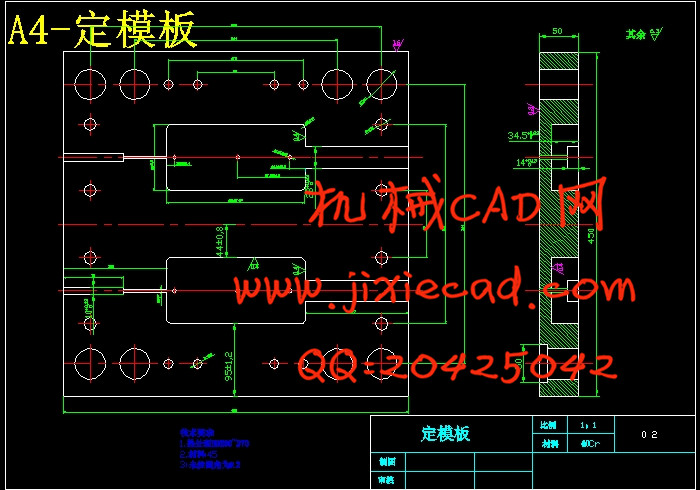

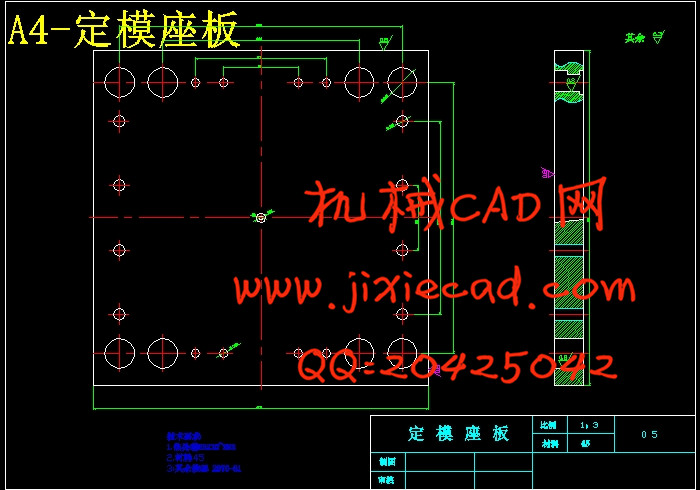

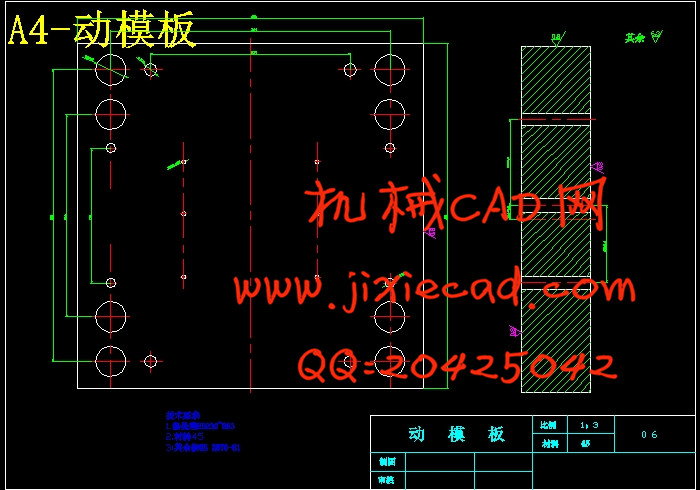

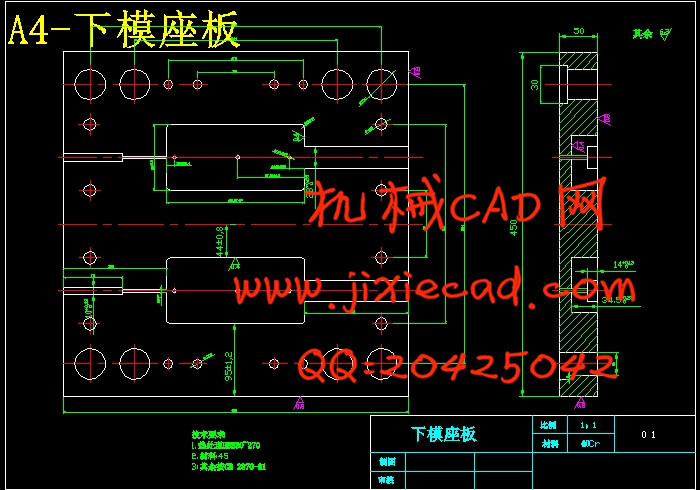

2.7成型零部件的结构设计-----------------------16

第3章 模具设计的有关计算 --------------------- 22

第4章 模具加热与冷却系统的计算---------------- 24

第5章 模具闭合高度的确定 --------------------- 26

第6章 注塑机有关参数的校核----------------------27

第7章 绘制模具总装图和非标准零件工作图----------28

第8章 注塑模主要零件加工工艺规程的编制----------29

第9章 模具的安装与调试 ------------------------ 30

9.1模具的安装---------------------------------30

9.2模具的调试 ------------------------------- 31

设计总结 -----------------------------------------32

致谢 ---------------------------------------------33

参考文献 -----------------------------------------34

摘要

分析了PA1010塑料的特性及其对注塑工艺的影响,介绍了套筒注塑模主要零部件的尺寸计算方法,注塑模结构及工作过程。根据套筒零件的特点确定了注塑模结构,并且模具结构设计精巧,达到了塑件的尺寸精度。

针对塑件脱模过程中的难点,设计了一种非常规抽芯的注塑模结构,并对模具设计与制造中的一些关键问题加以详述。由于该模具需要3个方向抽芯,因此选择了多种侧向分型机构,并对其中之一作了重点介绍,同时对浇注系统,顶出机构也作了简要说明。

实践证明,该模具设计合理,动作可靠,对同类塑件的注塑模设计有一定的参考价值。

关键词:PA1010塑料 ;注塑模 ;设计 ;套筒 ;抽芯机构;侧向抽芯。

(Design of the Cylindrical bush Injection Mould)

Abstract

The properties of the PA1010 plastics and their influences to the moulding technology are analyzed. The structure and working process of the cylindrical bush injection mould are introduced.And the dimension calculations for some key components of the mould are stated.Thestructure of the injection mould for the cylindrical bush has been determined according to it’s characteristics . The design of the mould structure is smart and the operation of the mould is easy. The plastic parts moulded with the mould have reached the required dimension precision .

According to the difficulty in the plastic part demoulding process ,an injection mould with non-tradional core-pulling mechanism has been designed. And some key points in design and manufacture of the mould are stated in detail. Since the mould requires core-pulling on three directions ,various side parting mechanisms have been used and one of them is mainly introduced .The feed system and the ejector mechanism are briefly introduced .

Practices show that the mould are design is reasonable and the mould movement is reliable. It can serve as a reference to the design of the moulds for similar parts.

Key words:PA1010plastic;injection mould; design;

Cylindrical bush;core-pulling;side parting.

绪论----------------------------------------------1

第1章 模塑工艺规程的编制-----------------------5

1.1塑件的工艺性分析--------------------------5

1.2计算塑件体积和质量------------------------7

1.3塑件注塑工艺参数的确定--------------------8

第2章 注塑模的机构设计--------------------------9

2.1分型面的选择------------------------------ 9

2.2确定型腔的排列方式------------------------10

2.3浇注系统设计 -----------------------------11

2.4抽芯机构设计 -----------------------------13

2.5推出机构设计 -----------------------------15

2.6合模导向机构设计------------------------- 16

2.7成型零部件的结构设计-----------------------16

第3章 模具设计的有关计算 --------------------- 22

第4章 模具加热与冷却系统的计算---------------- 24

第5章 模具闭合高度的确定 --------------------- 26

第6章 注塑机有关参数的校核----------------------27

第7章 绘制模具总装图和非标准零件工作图----------28

第8章 注塑模主要零件加工工艺规程的编制----------29

第9章 模具的安装与调试 ------------------------ 30

9.1模具的安装---------------------------------30

9.2模具的调试 ------------------------------- 31

设计总结 -----------------------------------------32

致谢 ---------------------------------------------33

参考文献 -----------------------------------------34