设计简介

摘要

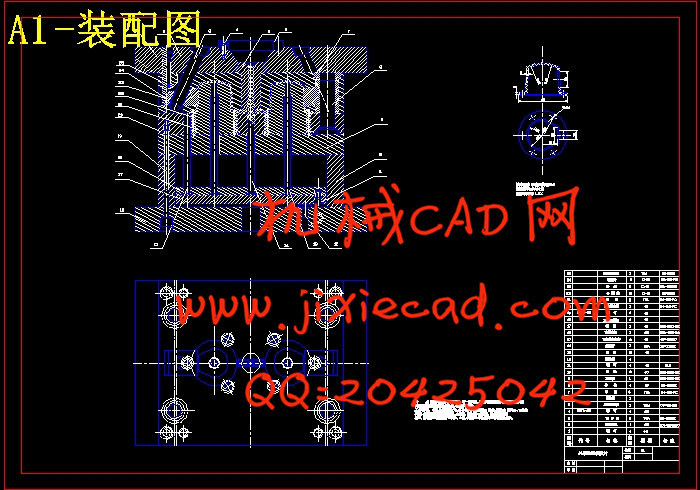

本设计是典型的塑料外罩注塑模具,通过对塑件的材料、 塑件的结构和尺寸精度及表面质量分析以及工艺方案的确定、分型面的选择、工艺计算等,考虑到模具制造问题、造价,结合前人的经验总结,提出了本模具的结构方案。

本模具采用一模两腔进行生产,效率比较高。其浇注系统采用侧浇口,梯形的分流道,充模速度快,安全可靠。模具在结构上采用了斜导柱抽芯机构,大大降低工人的了劳动强度,使模具在生产过程中操做更加方便。

本设计在设计过程中得到了于原红玲等几位老师的亲自指导同时也得到了翟德梅、杨占尧等几位高级工程师的大力支持和帮助,再此表示诚挚的感谢!由于编者水平有限,收集资料困难,如果有不尽人意的地方,还望各位老师批评指正,提出宝贵的改进意见!

关键词:注塑模具 分型面 浇注系统 斜导柱抽芯机构 侧浇口

Abstract

This design is the typical plastic shell casts the mold, through to models a material, models a structure and the size precision and the surface quality analysis as well as the craft plan determination, divides the profile the choice, the process design and so on, considered to the mold manufacture question, the construction cost, unifies predecessor's experience summary, proposed this mold structure plan.

This mold uses mold two cavities to carry on the production, the efficiency quite is high. It pours the system to use the side runner, the trapezoidal minute flow channel, the sufficient mold speed quick, safe is reliable. The mold used the slanting guide pillar in the structure to pull out the core organization, reduced the worker greatly the labor intensity, caused the mold to hold in the production process does conveniently.

This design obtained Yu Yuan hong Ling during the design process and so on several teachers' personal instructions also to obtain Zhai De mei, Yang Zhan yao and so on several seniors level limited, the data collection is difficult, if has the place which is unsatisfactory, but also looks fellow teachers to criticize points out mistakes, to give the precious improvement comment!

Key words: Casts the mold Minute profile Pours the system The slanting guide pillar pulls out the core organization Side runner

目 录

绪论------------------------------------------------------------------------------------------1

第一章 任务来源及设计目的意义

1.1设计任务来源------------------------------------------------------------------3

1.2设计目的及意义---------------------------------------------------------------3

第二章 零件的工艺性分析

2.1塑件的原材料分析------------------------------------------------------------4

2.2塑件的结构和尺寸精度及表面质量分析---------------------------------5

2.3计算塑件的体积和质量------------------------------------------------------6

2.4塑件注塑工艺参数的确定---------------------------------------------------6

第三章 工艺方案的确定

3.1.分型面选择----------------------------------------------------------------------8

3.2.确定型腔的排列方式----------------------------------------------------------8

3.3.浇注系统的设计----------------------------------------------------------------9

第四章 模具结构设计与校核

4.1.抽芯机构设计------------------------------------------------------------------12

4.2.滑块与导滑槽设计------------------------------------------------------------15

4.3导柱、导套设计---------------------------------------------------------------15

4.4成型零件结构设计------------------------------------------------------------16

第五章 模具设计的有关计算

5.1 型腔和型芯工作尺寸计算---------------------------------------------------17

5.2.型腔侧壁厚度和底板厚度计算----------------------------------------------18

5.3.模具加热与冷却系统的计算-------------------------------------------------19

第六章 模具闭合高度和注塑机有关参数的校核----------------------------------21

第七章 编写主要工作零件加工工艺规程

7.1 型芯的加工工艺--------------------------------------------------------------22

7.2 型腔的加工工艺---------------------------------------------------------------24

设计总结--------------------------------------------------------------------------------------26

致谢--------------------------------------------------------------------------------------------27

参考文献--------------------------------------------------------------------------------------28

本设计是典型的塑料外罩注塑模具,通过对塑件的材料、 塑件的结构和尺寸精度及表面质量分析以及工艺方案的确定、分型面的选择、工艺计算等,考虑到模具制造问题、造价,结合前人的经验总结,提出了本模具的结构方案。

本模具采用一模两腔进行生产,效率比较高。其浇注系统采用侧浇口,梯形的分流道,充模速度快,安全可靠。模具在结构上采用了斜导柱抽芯机构,大大降低工人的了劳动强度,使模具在生产过程中操做更加方便。

本设计在设计过程中得到了于原红玲等几位老师的亲自指导同时也得到了翟德梅、杨占尧等几位高级工程师的大力支持和帮助,再此表示诚挚的感谢!由于编者水平有限,收集资料困难,如果有不尽人意的地方,还望各位老师批评指正,提出宝贵的改进意见!

关键词:注塑模具 分型面 浇注系统 斜导柱抽芯机构 侧浇口

Abstract

This design is the typical plastic shell casts the mold, through to models a material, models a structure and the size precision and the surface quality analysis as well as the craft plan determination, divides the profile the choice, the process design and so on, considered to the mold manufacture question, the construction cost, unifies predecessor's experience summary, proposed this mold structure plan.

This mold uses mold two cavities to carry on the production, the efficiency quite is high. It pours the system to use the side runner, the trapezoidal minute flow channel, the sufficient mold speed quick, safe is reliable. The mold used the slanting guide pillar in the structure to pull out the core organization, reduced the worker greatly the labor intensity, caused the mold to hold in the production process does conveniently.

This design obtained Yu Yuan hong Ling during the design process and so on several teachers' personal instructions also to obtain Zhai De mei, Yang Zhan yao and so on several seniors level limited, the data collection is difficult, if has the place which is unsatisfactory, but also looks fellow teachers to criticize points out mistakes, to give the precious improvement comment!

Key words: Casts the mold Minute profile Pours the system The slanting guide pillar pulls out the core organization Side runner

目 录

绪论------------------------------------------------------------------------------------------1

第一章 任务来源及设计目的意义

1.1设计任务来源------------------------------------------------------------------3

1.2设计目的及意义---------------------------------------------------------------3

第二章 零件的工艺性分析

2.1塑件的原材料分析------------------------------------------------------------4

2.2塑件的结构和尺寸精度及表面质量分析---------------------------------5

2.3计算塑件的体积和质量------------------------------------------------------6

2.4塑件注塑工艺参数的确定---------------------------------------------------6

第三章 工艺方案的确定

3.1.分型面选择----------------------------------------------------------------------8

3.2.确定型腔的排列方式----------------------------------------------------------8

3.3.浇注系统的设计----------------------------------------------------------------9

第四章 模具结构设计与校核

4.1.抽芯机构设计------------------------------------------------------------------12

4.2.滑块与导滑槽设计------------------------------------------------------------15

4.3导柱、导套设计---------------------------------------------------------------15

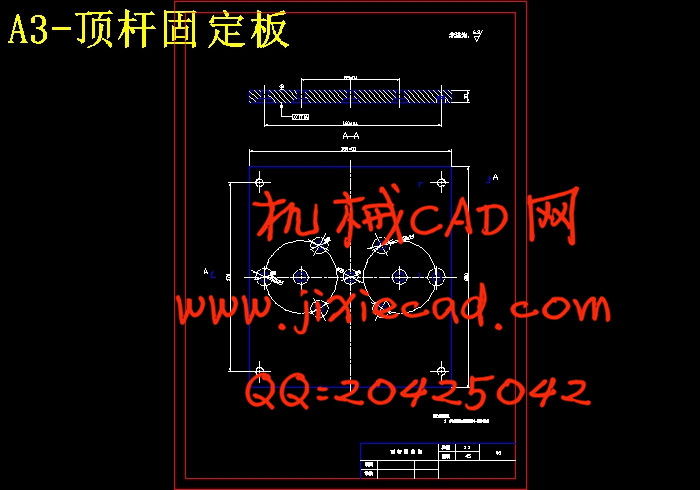

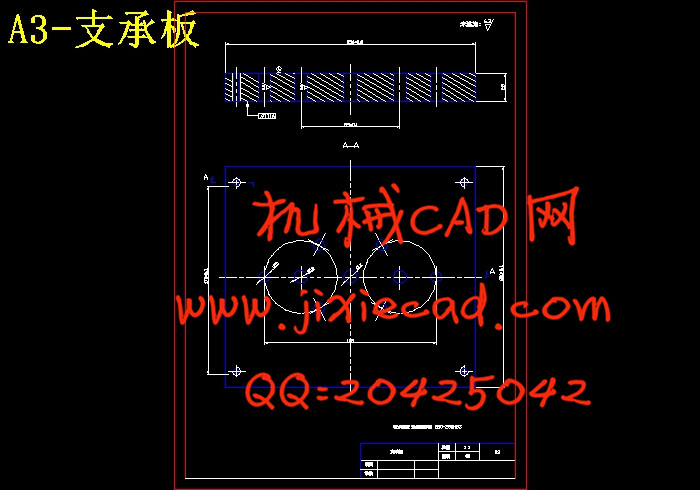

4.4成型零件结构设计------------------------------------------------------------16

第五章 模具设计的有关计算

5.1 型腔和型芯工作尺寸计算---------------------------------------------------17

5.2.型腔侧壁厚度和底板厚度计算----------------------------------------------18

5.3.模具加热与冷却系统的计算-------------------------------------------------19

第六章 模具闭合高度和注塑机有关参数的校核----------------------------------21

第七章 编写主要工作零件加工工艺规程

7.1 型芯的加工工艺--------------------------------------------------------------22

7.2 型腔的加工工艺---------------------------------------------------------------24

设计总结--------------------------------------------------------------------------------------26

致谢--------------------------------------------------------------------------------------------27

参考文献--------------------------------------------------------------------------------------28