设计简介

近几年国家振兴机械行业,与机械相关的各个行业都越来越重视CAD/CAM技术,不仅是因为CAD/CAM技术已发展成为一项比较成熟的共性技术,同时还因为塑料制品及模具的3D设计与成型过程中3D分析正在塑料模具工业中发挥越来越重要的作用。在本次毕业设计中,通过运用三维实体造型高端软件Pro/Engineer(简称Pro/E)对“万向轮支座”外形进行3D造型,同时也设计了其塑料外壳注塑模的3D模型;还根据所设计的模具尺寸选择安装了相应的模架,最终生成了直观的结构设计图;此外还利用CAD绘制了模具装配图以及各种成型零件图。这是第一次利用绘图软件对整套模具进行设计,对所学知识进行了全面巩固,意义重大!

关键词 壳体 注塑模 实体造型 模具 模架

Abstract

Over the past few years the country vitalizes machinery industry, each industry that related with mechanics is all paying more and more attention to the CAD/CAM technology. That is not only because CAD/CAM technology has already been developed into one ripe generality technology, but also because 3D design of Plastics piece make and mould and 3D analysis of molding process plays a more and more important role in plastics mould industry. In the graduation project, through using 3D entity sculpting software Pro/Engineer (Pro/E for short), I build 3D mold of “The Rotary round support ”, also build the plastics injection 3D mold of the shell crust at the same time. I chose the appropriate mold frame and made it fixed with the mold, according to the measurement of the mold. Finally I do the intuitionist drawing of 3D mold as well. In addition, also has drawn up the mold assembly drawing as well as each kind of Molding Parts drawing using CAD. This is that the first time makes use of the software drawing to carry out design on package mould , have carried out all-round consolidation on what be learned knowledge,The significance is significant!

Keywords Shell Plastics injection mold Solid mold Mold Mold fram

目 录

摘 要 Ⅰ

Abstract Ⅱ

1 绪论 1

1.1 我国塑料模具业发展现状及方向 1

1.2 pro/E简介及在模具设计中的应用 4

2 壳体设计及其成型工艺的分析 5

2.1 塑件分析 5

2.2 塑料的选材及性能分析 5

2.3 热塑性塑料的注射过程及工艺 6

2.4 塑料的主要缺陷及消除措施 7

3 壳体模具设计方案的比较与确定 9

3.1 分型面方案的优化与确定 9

3.2 型腔数量以及排列方式的优化确定 10

3.3 模具设计方案的创新与确定 11

4 模具设计与对比创新 12

4.1 注塑机选型 12

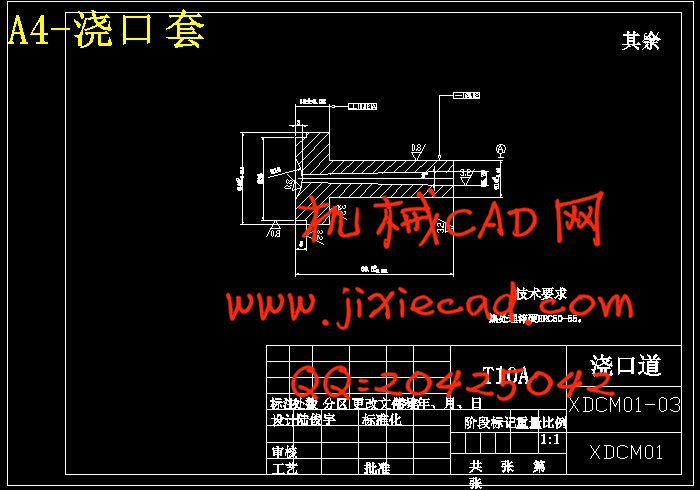

4.2 模具浇注系统设计和浇口的设计 15

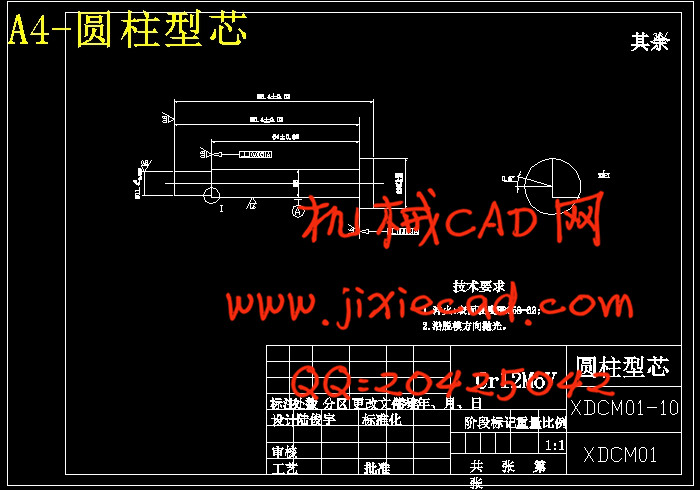

4.3 成型零件的结构设计和计算 18

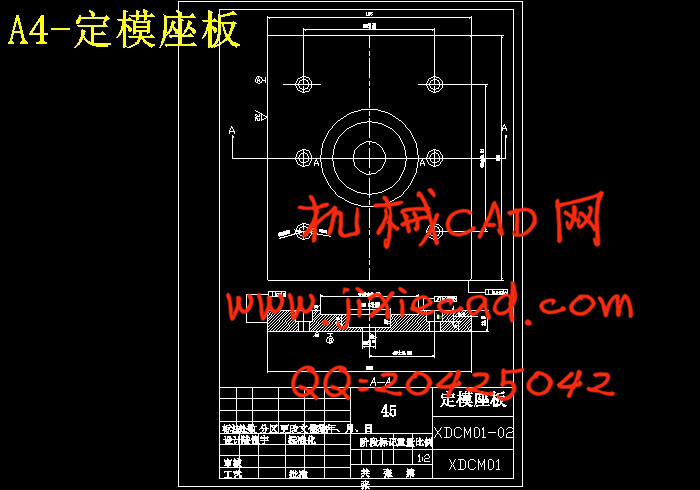

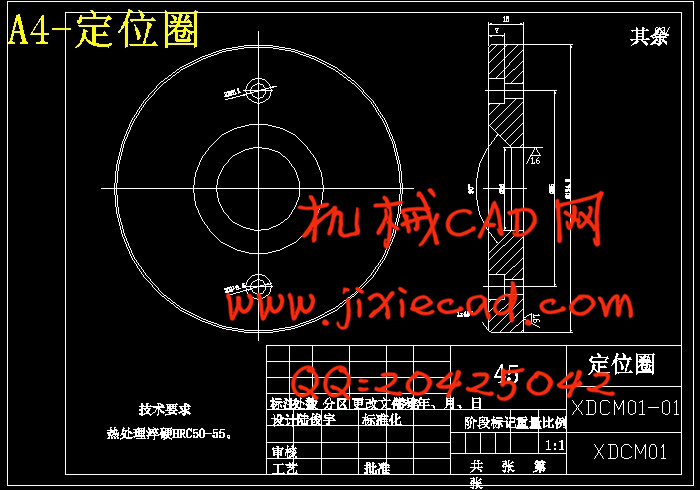

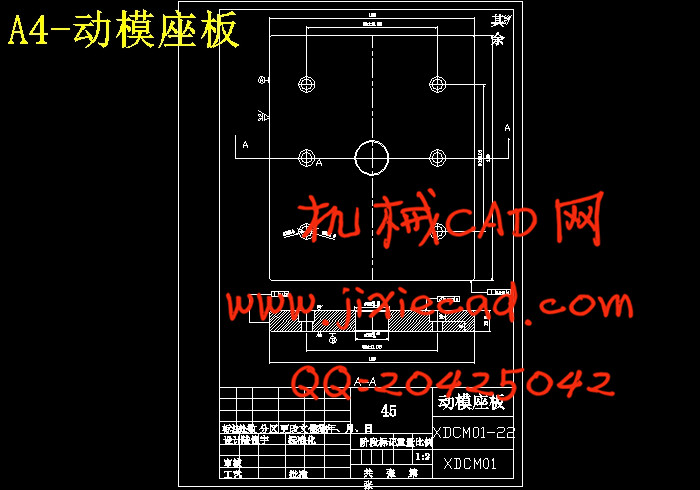

4.4 模架的确定和标准件的选用 21

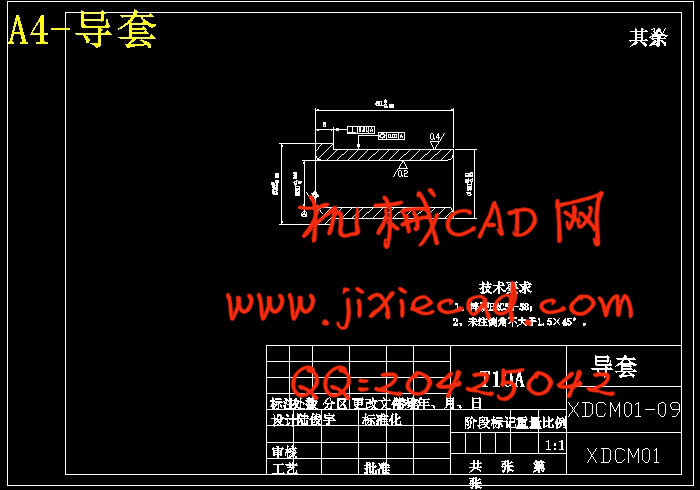

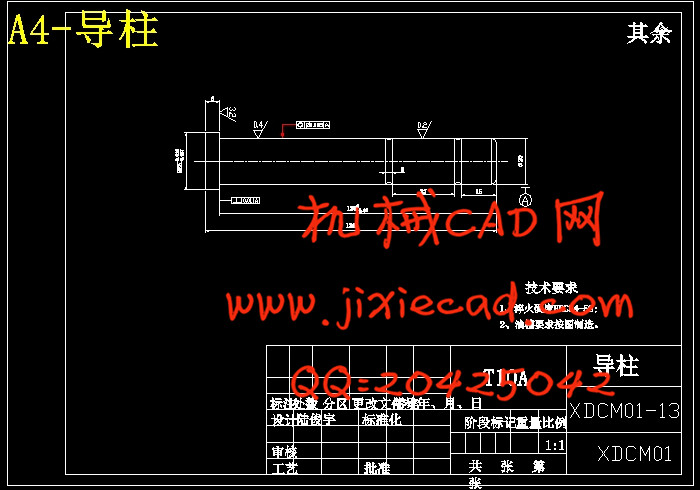

4.5 合模导向机构和定位机构 22

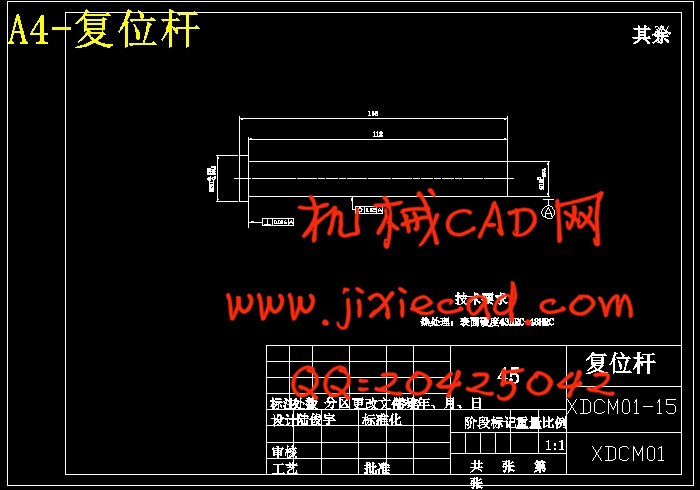

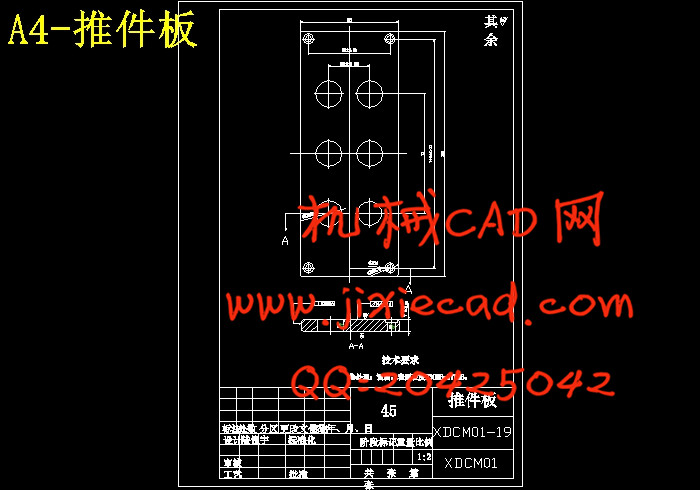

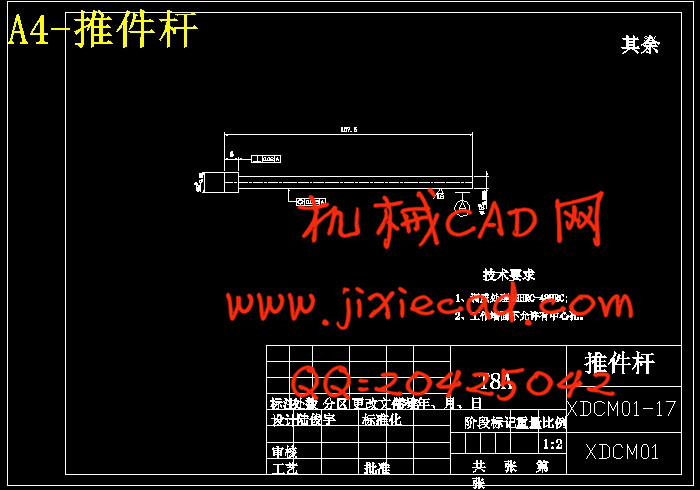

4.6 脱模机构设计 24

4.7 侧向分型与抽芯机构设计 25

4.8 排气系统的设计 26

4.9 冷却系统的优化设计 27

4.10 模具材料例表 28

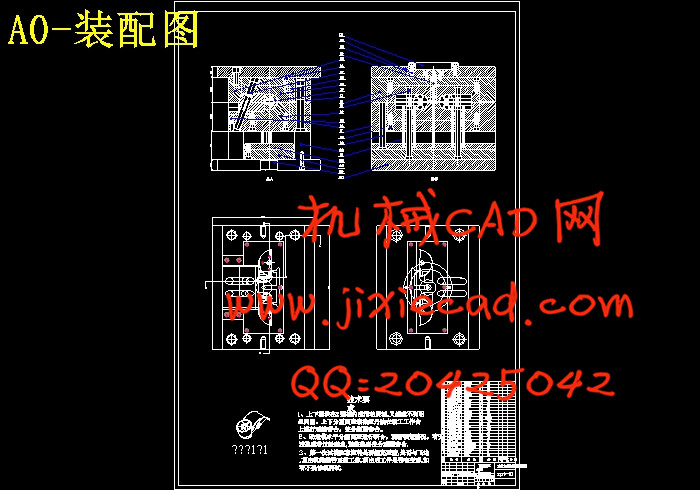

5 模具装配 30

5.1 塑料模具装配的技术要求 30

5.2 塑料模具装配过程 30

6 模具工作过程 33

结束语 34

致谢 36

参考文献 37

关键词 壳体 注塑模 实体造型 模具 模架

Abstract

Over the past few years the country vitalizes machinery industry, each industry that related with mechanics is all paying more and more attention to the CAD/CAM technology. That is not only because CAD/CAM technology has already been developed into one ripe generality technology, but also because 3D design of Plastics piece make and mould and 3D analysis of molding process plays a more and more important role in plastics mould industry. In the graduation project, through using 3D entity sculpting software Pro/Engineer (Pro/E for short), I build 3D mold of “The Rotary round support ”, also build the plastics injection 3D mold of the shell crust at the same time. I chose the appropriate mold frame and made it fixed with the mold, according to the measurement of the mold. Finally I do the intuitionist drawing of 3D mold as well. In addition, also has drawn up the mold assembly drawing as well as each kind of Molding Parts drawing using CAD. This is that the first time makes use of the software drawing to carry out design on package mould , have carried out all-round consolidation on what be learned knowledge,The significance is significant!

Keywords Shell Plastics injection mold Solid mold Mold Mold fram

目 录

摘 要 Ⅰ

Abstract Ⅱ

1 绪论 1

1.1 我国塑料模具业发展现状及方向 1

1.2 pro/E简介及在模具设计中的应用 4

2 壳体设计及其成型工艺的分析 5

2.1 塑件分析 5

2.2 塑料的选材及性能分析 5

2.3 热塑性塑料的注射过程及工艺 6

2.4 塑料的主要缺陷及消除措施 7

3 壳体模具设计方案的比较与确定 9

3.1 分型面方案的优化与确定 9

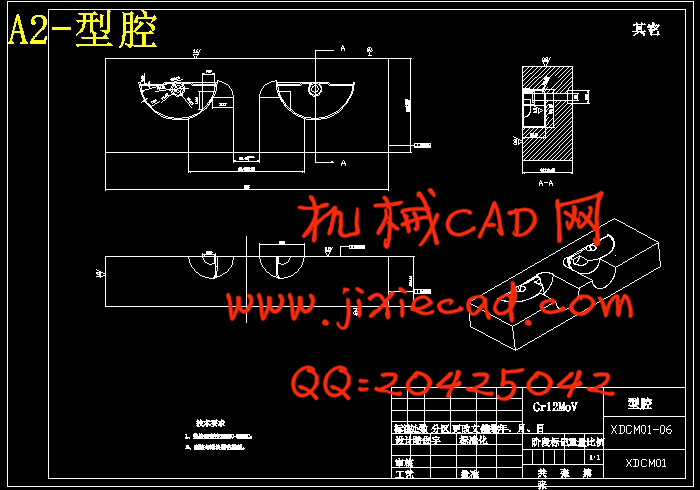

3.2 型腔数量以及排列方式的优化确定 10

3.3 模具设计方案的创新与确定 11

4 模具设计与对比创新 12

4.1 注塑机选型 12

4.2 模具浇注系统设计和浇口的设计 15

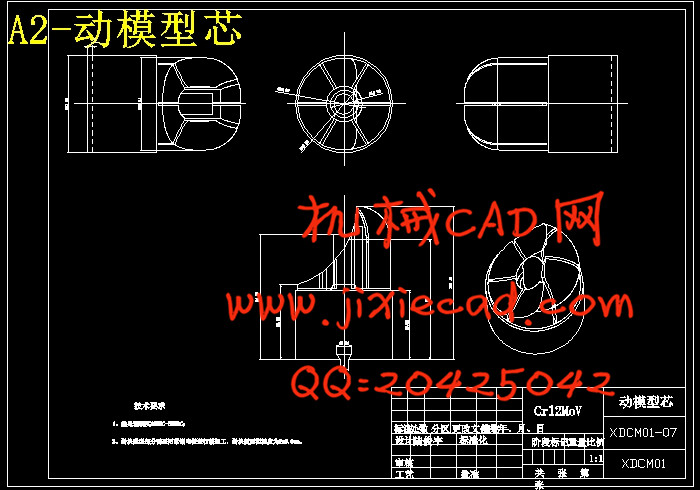

4.3 成型零件的结构设计和计算 18

4.4 模架的确定和标准件的选用 21

4.5 合模导向机构和定位机构 22

4.6 脱模机构设计 24

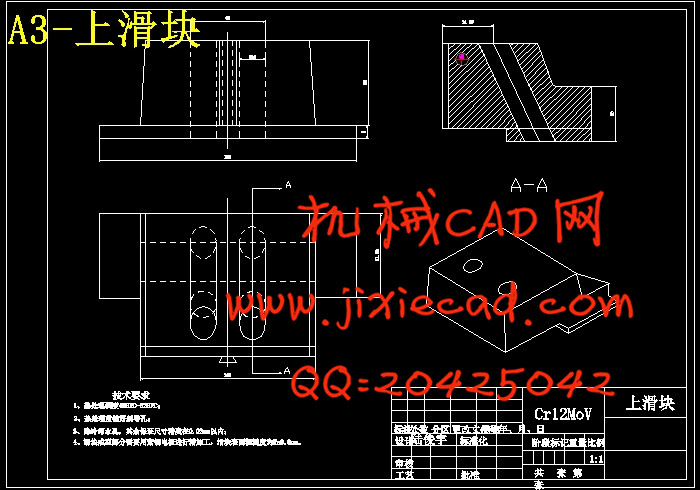

4.7 侧向分型与抽芯机构设计 25

4.8 排气系统的设计 26

4.9 冷却系统的优化设计 27

4.10 模具材料例表 28

5 模具装配 30

5.1 塑料模具装配的技术要求 30

5.2 塑料模具装配过程 30

6 模具工作过程 33

结束语 34

致谢 36

参考文献 37