设计简介

摘要

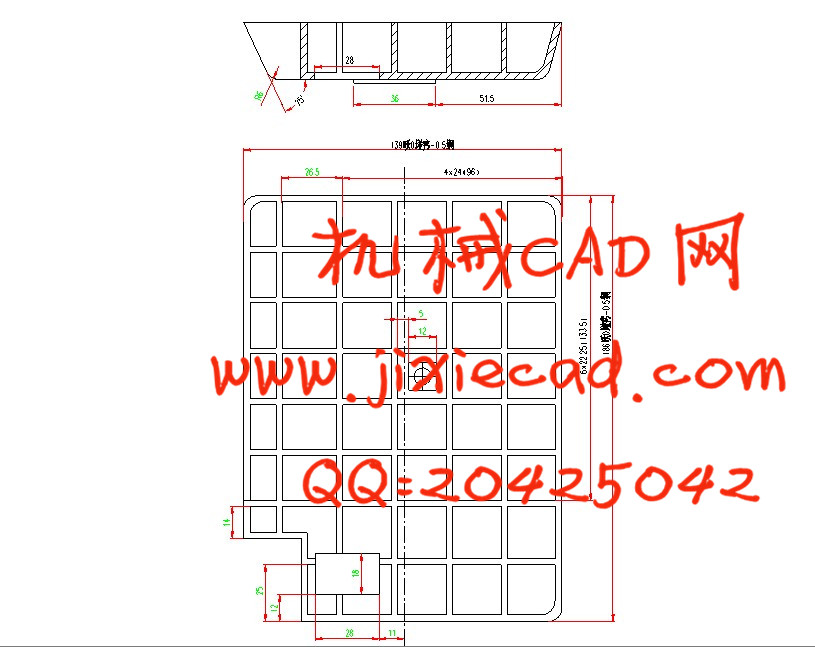

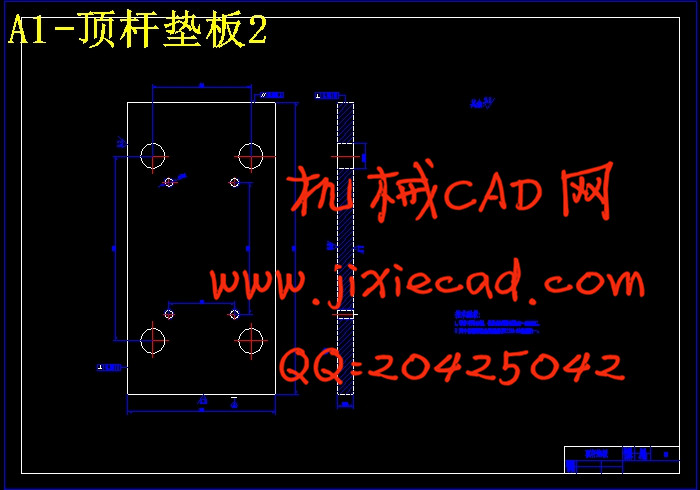

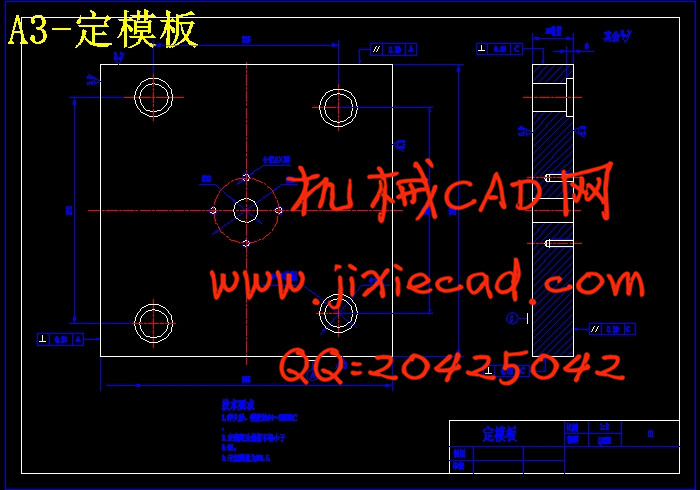

本课题设计的是:温控器垫块注塑模的结构与设计,本模具温控器垫块注塑模,材料采用ABS(丙烯腈-丁二烯-苯乙烯),属热塑性塑料。因制件底板面积较大,而壁厚较小,同时制件的高度相对较低,为保证塑件的刚性,防止塑件发生变形,所以在制件上设置了成网格状分布的加强筋,与此对应在设计中成型零件采用整体式凸模,凸模可用电火花加工成;为保证成型后塑件的脱出,所以模具中的顶出机构采用了顶杆顶出,设计中采用顶杆,根据制品特点,顶杆形状采用异形顶杆,且在模具上均衡布置;在模具的浇注系统中采用点浇口进料,为便于浇注系统凝料的脱出,需要在模具上增加一个分型面,所以设计中将其中一导柱设计成了拉杆导柱的形式,即:在导柱尾部加一垫圈和螺母,利用拉杆导柱的作用加设一分型面取出凝料;另外由于制品加强筋较深,冷却时间较长,所以型腔部分需采用冷却水冷却,经计算模具结构中设置了冷却水道。

关键词:双分型面 异形顶杆 拉杆导柱 冷却水道

Abstract

This topic designs the mold is the thread note molds. This mold is the typical three board style mold, namely the duplex profile note molds, the duplex profile note molds has two profiles, when operates the mold, the mold first pours the system after I - I minute minute to congeal the material from this to take out; Continues to operate the mold, the mold along II - II minute, after dividing models from this to leave. This models the material which uses is the fluidity and the formability fine, the rate of finished products high, but is easy to appear the crack, takes shape models drawing of patterns ascent not suitable small PS. For is advantageous for the product in the injection process to take shape, should reduce the plastic in injection process flow as far as possible. In order to does not affect models a outward appearance and operational performance this mold uses the runner form. In order to take shape models a box thread to be partial, needs a thread core. This mold uses outside the mold the manual drawing of patterns way, when operates the mold is taken for the guarantee thread core moves the mold, has established the clamp installment which is composed by the ring-like extension spring and the clamp. In order to guarantee the production the continuity, the thread core should have the spare parts, by supplies the circulation use.

Key word: Duplex flour dim sumrunner thread core clamp installment

中英文摘要 ………………………………………………2

绪论 ………………………………………………………8

第1章 模塑工艺规程的编制 …………………………9

1.1 塑件的工艺性分析 ……………………………………9

1.2 计算塑件的体积和质量……………………………………11

1.3 塑件注塑工艺参数的确定 ……………………………11

1.4 注塑机部分工艺参数校核 ………………………………13

第2章 注塑模浇注及排气系统的结构设计 ………15

2.1 浇注系统的结构设计………………………………………15

2.2 排气系统的设计………………………………………17

第3章 模具成型零部件的结构设计及计算…………18

3.1 凸凹模的结构设计…………………………………………18

3.2 成型零件的材料选用………………………………………19

3.3 成型零部件的有关计算……………………………………20

第4章 模具的结构与辅助零部件设计………………21

4.1 脱模机构的设计……………………………………………21

4.2 支承与连接零部件的设计与选择…………………………25

4.3 合模导向机构的设计………………………………………26

第5章 温度调节与控制系统设计……………………29

5.1 温度调节与控制系统计算…………………………………29

5.2 冷却水道的布局……………………………………………30

第6章 模具闭合高度的确定…………………………31

第7章 注塑机有关安装参数的校核…………………32

7.1 喷嘴尺寸校核………………………………………………32

7.2 定位圈尺寸校核……………………………………………32

7.3 模具固定尺寸校核…………………………………………32

7.4 模具厚度校核………………………………………………33

7.5 模具开模行程校核…………………………………………33

第8章 绘制模具总装图及非标零件图………………34

结论 ……………………………………………………35

致谢 ……………………………………………………37

参考文献 ………………………………………………38

本课题设计的是:温控器垫块注塑模的结构与设计,本模具温控器垫块注塑模,材料采用ABS(丙烯腈-丁二烯-苯乙烯),属热塑性塑料。因制件底板面积较大,而壁厚较小,同时制件的高度相对较低,为保证塑件的刚性,防止塑件发生变形,所以在制件上设置了成网格状分布的加强筋,与此对应在设计中成型零件采用整体式凸模,凸模可用电火花加工成;为保证成型后塑件的脱出,所以模具中的顶出机构采用了顶杆顶出,设计中采用顶杆,根据制品特点,顶杆形状采用异形顶杆,且在模具上均衡布置;在模具的浇注系统中采用点浇口进料,为便于浇注系统凝料的脱出,需要在模具上增加一个分型面,所以设计中将其中一导柱设计成了拉杆导柱的形式,即:在导柱尾部加一垫圈和螺母,利用拉杆导柱的作用加设一分型面取出凝料;另外由于制品加强筋较深,冷却时间较长,所以型腔部分需采用冷却水冷却,经计算模具结构中设置了冷却水道。

关键词:双分型面 异形顶杆 拉杆导柱 冷却水道

Abstract

This topic designs the mold is the thread note molds. This mold is the typical three board style mold, namely the duplex profile note molds, the duplex profile note molds has two profiles, when operates the mold, the mold first pours the system after I - I minute minute to congeal the material from this to take out; Continues to operate the mold, the mold along II - II minute, after dividing models from this to leave. This models the material which uses is the fluidity and the formability fine, the rate of finished products high, but is easy to appear the crack, takes shape models drawing of patterns ascent not suitable small PS. For is advantageous for the product in the injection process to take shape, should reduce the plastic in injection process flow as far as possible. In order to does not affect models a outward appearance and operational performance this mold uses the runner form. In order to take shape models a box thread to be partial, needs a thread core. This mold uses outside the mold the manual drawing of patterns way, when operates the mold is taken for the guarantee thread core moves the mold, has established the clamp installment which is composed by the ring-like extension spring and the clamp. In order to guarantee the production the continuity, the thread core should have the spare parts, by supplies the circulation use.

Key word: Duplex flour dim sumrunner thread core clamp installment

中英文摘要 ………………………………………………2

绪论 ………………………………………………………8

第1章 模塑工艺规程的编制 …………………………9

1.1 塑件的工艺性分析 ……………………………………9

1.2 计算塑件的体积和质量……………………………………11

1.3 塑件注塑工艺参数的确定 ……………………………11

1.4 注塑机部分工艺参数校核 ………………………………13

第2章 注塑模浇注及排气系统的结构设计 ………15

2.1 浇注系统的结构设计………………………………………15

2.2 排气系统的设计………………………………………17

第3章 模具成型零部件的结构设计及计算…………18

3.1 凸凹模的结构设计…………………………………………18

3.2 成型零件的材料选用………………………………………19

3.3 成型零部件的有关计算……………………………………20

第4章 模具的结构与辅助零部件设计………………21

4.1 脱模机构的设计……………………………………………21

4.2 支承与连接零部件的设计与选择…………………………25

4.3 合模导向机构的设计………………………………………26

第5章 温度调节与控制系统设计……………………29

5.1 温度调节与控制系统计算…………………………………29

5.2 冷却水道的布局……………………………………………30

第6章 模具闭合高度的确定…………………………31

第7章 注塑机有关安装参数的校核…………………32

7.1 喷嘴尺寸校核………………………………………………32

7.2 定位圈尺寸校核……………………………………………32

7.3 模具固定尺寸校核…………………………………………32

7.4 模具厚度校核………………………………………………33

7.5 模具开模行程校核…………………………………………33

第8章 绘制模具总装图及非标零件图………………34

结论 ……………………………………………………35

致谢 ……………………………………………………37

参考文献 ………………………………………………38