设计简介

摘 要

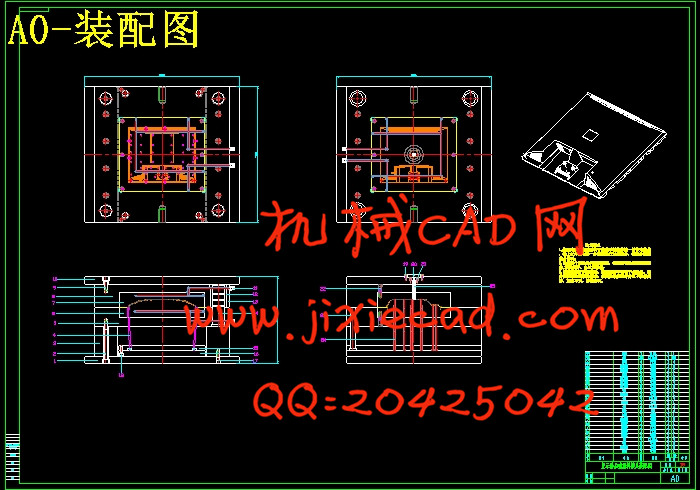

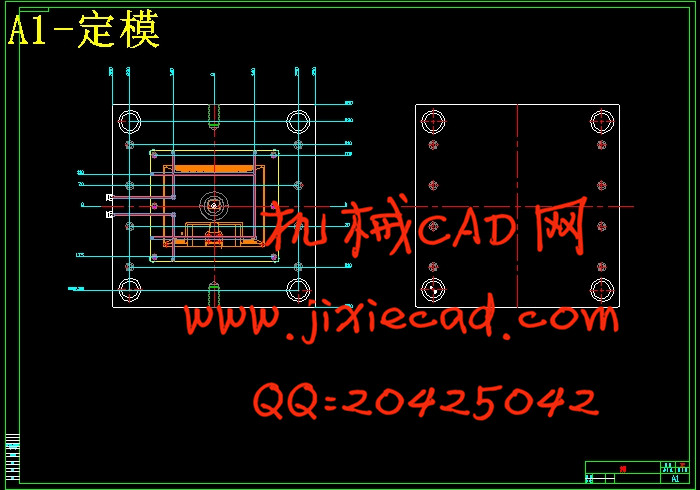

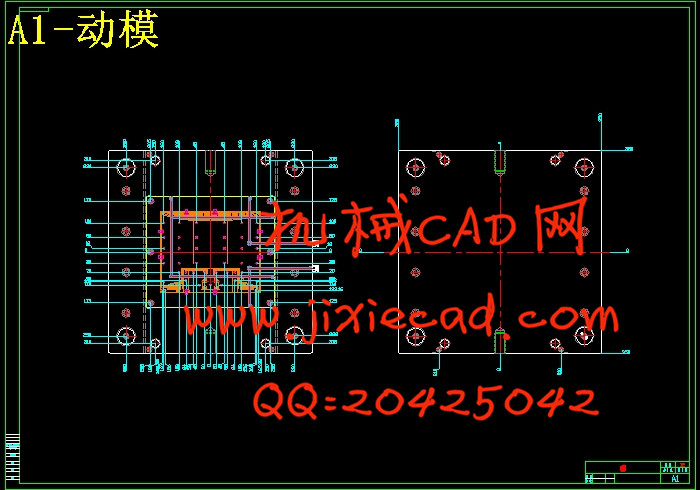

近年来在我国工业化快速推进的同时,在国民经济中占有重要地位的模具工业也得到了迅速发展。统计显示,1996至2001年,我国模具制造业的产值年均增长14%到15%。2001年我国模具总产值就已突破300多亿元人民币,排名跃居世界第四位。虽然近几年来,我国模具工业的技术水平已取得了很大的进步,但总体上与工业发达的国家相比仍有较大的差距。此次的设计任务即显示器后壳模具设计,首先我使用模具设计软件建立产品的2D、3D模型,并对其模具设计!再用所学的注塑模设计,以及机械设计等方面的知识,利用模具设计软件对塑件进行了实体造型,对塑件结构进行了工艺分析。然后明确了设计思路,确定了注射成型工艺过程并对各个具体部分进行了详细的计算和校核。如此设计出的结构可确保模具工作运用可靠,保证了与其他部件的配合。最后用AUTOCAD绘制了一套模具装配图和零件图。

本课题通过对显示器后壳底板的注射模具设计,巩固和深化了所学知识,取得了比较满意的效果,达到了预期的设计意图

关键词:注塑模设计 实体造型 工艺分析 模具设计

ABSTRACT

At the same time, the rapid advance of industrialization in our country in recent years in the national economy occupies an important position in the mold industry has got rapid development. Statistics show that from 1996 to 2001, our country mold manufacturing output grew by an average of 14% to 15%. Mould of 2001, China's total output value has reached more than 300 300 yuan, ranked as the fourth in the world. Although in recent years, mould industry technology level in China has made great progress, but on the whole, compared with developed countries still have larger gap. After the design tasks which display shell mold design, first of all, I use mold design software, 2 d and 3 d model of building products, and the mold design! Then use what they have learned the injection mold design, and mechanical design knowledge, the use of plastic parts mold design software entity modelling, has carried on the structure of plastic parts process analysis. Then clear the design ideas, to determine the injection molding process and to each specific parts of detailed calculation and checking. Such a structure are designed, which can ensure the mold work using reliable, to ensure the cooperation with other parts. Finally using AUTOCAD drawing a set of mold assembly drawing and part drawing.

This topic through to the display after the shell plate of injection mold design, consolidate and deepen the knowledge, and achieved satisfactory results, achieved the desired design intent

Keywords: Injection mold design Entity modeling Process analysis The mold design

近年来在我国工业化快速推进的同时,在国民经济中占有重要地位的模具工业也得到了迅速发展。统计显示,1996至2001年,我国模具制造业的产值年均增长14%到15%。2001年我国模具总产值就已突破300多亿元人民币,排名跃居世界第四位。虽然近几年来,我国模具工业的技术水平已取得了很大的进步,但总体上与工业发达的国家相比仍有较大的差距。此次的设计任务即显示器后壳模具设计,首先我使用模具设计软件建立产品的2D、3D模型,并对其模具设计!再用所学的注塑模设计,以及机械设计等方面的知识,利用模具设计软件对塑件进行了实体造型,对塑件结构进行了工艺分析。然后明确了设计思路,确定了注射成型工艺过程并对各个具体部分进行了详细的计算和校核。如此设计出的结构可确保模具工作运用可靠,保证了与其他部件的配合。最后用AUTOCAD绘制了一套模具装配图和零件图。

本课题通过对显示器后壳底板的注射模具设计,巩固和深化了所学知识,取得了比较满意的效果,达到了预期的设计意图

关键词:注塑模设计 实体造型 工艺分析 模具设计

ABSTRACT

At the same time, the rapid advance of industrialization in our country in recent years in the national economy occupies an important position in the mold industry has got rapid development. Statistics show that from 1996 to 2001, our country mold manufacturing output grew by an average of 14% to 15%. Mould of 2001, China's total output value has reached more than 300 300 yuan, ranked as the fourth in the world. Although in recent years, mould industry technology level in China has made great progress, but on the whole, compared with developed countries still have larger gap. After the design tasks which display shell mold design, first of all, I use mold design software, 2 d and 3 d model of building products, and the mold design! Then use what they have learned the injection mold design, and mechanical design knowledge, the use of plastic parts mold design software entity modelling, has carried on the structure of plastic parts process analysis. Then clear the design ideas, to determine the injection molding process and to each specific parts of detailed calculation and checking. Such a structure are designed, which can ensure the mold work using reliable, to ensure the cooperation with other parts. Finally using AUTOCAD drawing a set of mold assembly drawing and part drawing.

This topic through to the display after the shell plate of injection mold design, consolidate and deepen the knowledge, and achieved satisfactory results, achieved the desired design intent

Keywords: Injection mold design Entity modeling Process analysis The mold design

目录

绪论 1

第一章 塑料模具相关知识综述 2

第二章 塑件成型工艺分析 3

2.1 产品开发依据用途清单 3

2.2 制品结构和形状的设计 3

2.3 制品材料选择 5

2.3.1 丙烯腈—丁二烯—苯乙烯三元共聚物(ABS) 5

2.3.2 聚苯乙烯(PS) 6

2.3.3 双酚A型聚碳酸酯(PC) 6

2.4 注射工艺选择 7

2.4.1 ABS塑料的干燥 7

2.4.2 注射压力 8

2.4.3 注射速度 8

2.4.4 模具温度 8

2.4.5 料量控制 8

第三章 模具与注射机的关系 9

3.1 塑件的体积计算 9

3.2 注射机的选择 9

第四章 注射模的结构设计 10

4.1 分型面的选择 10

4.2 确定型腔的数量及排列方式 11

第五章 浇注系统的设计 12

5.1 主流道设计 12

5.2 浇口设计 13

第六章 斜顶 15

6.1 斜滑块的组合 15

第七章 成型零件的设计 16

7.1 型腔径向尺寸计算(此题公差为自己标注) 16

7.2 型芯外径尺寸计算 16

7.3 型腔深度尺寸计算 16

7.4 型芯高度尺寸计算 17

7.5 两成型杆的中心距计算 17

第八章 脱模推出机构的设计与模架的选用 18

8.1 脱模推出机构的设计 18

8.2 模架的选用 18

第九章 注射机工艺参数校核 19

9.1 注射压力的校核 19

9.3 模具厚度的校核 19

9.4 开模行程的校核 19

第十章 模具冷却系统 20

第十一章 试模及模具维修 22

11.1 模具的安装 22

11.2 试模 22

11.3 模具的维修 22

第十二章 设计结果3D效果图片预览 23

第十三章 结论 26

参 考 文 献 27