设计简介

摘要

我所学习的专业是模具设计与制造专业,这次的毕业设计是线圈骨架产品造型与塑料模具设计。该设计结合大学三年来所学习的专业知识和CAD软件所设计出的一套塑料模。

本文首先简要的概述了塑料模在社会领域中的作用及其以后的发展方向,点明模具设计的重要意义。然后依据工件图进行工艺性分析,进而确定了设计方案,计算出模具工作部分的尺寸,设计出工作零部件;然后依据设计要求选择出各个标准零部件,然后设计出模具的总装配图。在设计中,最重要的就是设计方案的确定、坯料的计算和工作零部件的设计,这是设计的关键,这些设计的正确与否直接关系到成本的高低和设计模具能否正常工作;在设计的最后,总结了自己的心得和体会,并对我的指导老师表示感谢。

通过次毕业设计使我不仅掌握了塑料模具设计的一般流程,更学习到了好多课本上没有学习到的知识,使我受益非浅。

关键词:模具设计与制造、CAD软件、工艺性分析。

Abstract

knowledge of study and a set of plastic moulds that CAD software designed over the past three years of university.

This text the brief plastic role in social field of mould of summary and developing direction afterwards at first, point out in the important meaning of mold design. Then carry on the craft to analyse according to the work piece picture , and then has confirmed the design plan , calculate out mould work some size , design the job spare part; Then choose each standard spare part according to the designing requirement , then design the total installation diagram of the mould . In the design, the important one is sureness , calculation of the blank and design of the job spare part of the design plan the most, this is the key to designing, whether these ones that are designed involve directly or not correctly whether the level of the cost and design mould could work normally; At the end that is designed , have summarized one's own gains and experience , and express thanks for my counselor.

Make me not merely grasp the general procedure of plastic mold design through graduation project once, study to the knowledge not learning to get on many textbooks even more, benefit me a great deal.

Keyword: Mold design and making , CAD software , craft analysis.

第1章 注塑模结构与设计……………………………… …………………………….5

1.1 塑件的工艺型分析.............................................................................................5

1.2计算塑件的体积和质量......................................................................................6

1.3 塑件注塑工艺参数的确定..............................................................................6

第2章 注塑模结构设计.......................................................................................6

2.1:分型面选择...........................................................................................................6

2.2 确定型腔的排列方式.............................................................................................7

2.3浇注系统设计..........................................................................................................7

2.4 抽芯机构设计......................................................................................................8

第3章 模具的有关计算………………………………………………………………...10

第4章模具加热和冷却系统的计算………………………………………………..11

第5章模具闭合高度的确定……………………………………………………..……12

第6章注塑机有关参数的校核………..................…………………………………12

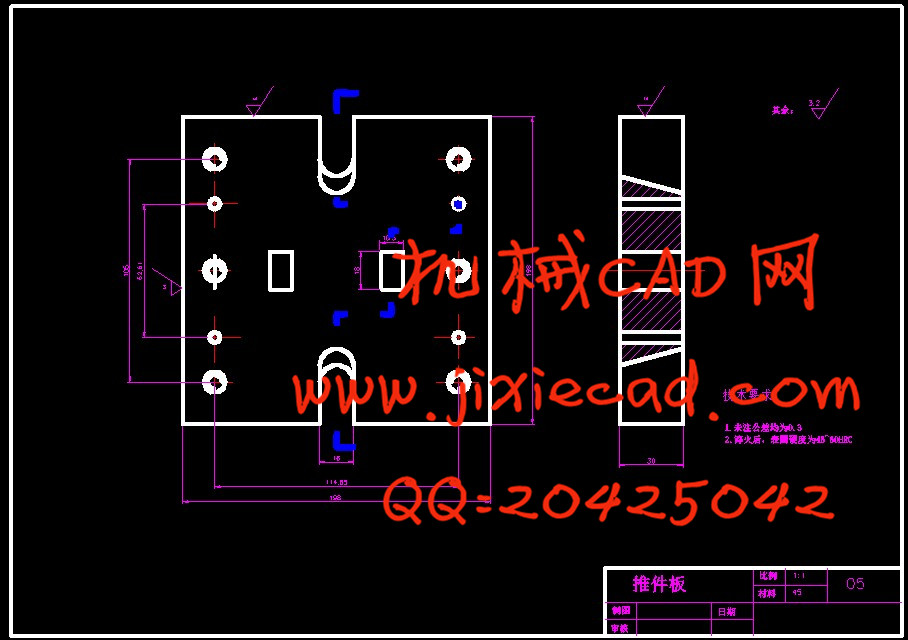

第7章绘制模具总装图………………………………………………………………….12

第8章模具的装配与调试…………………………………………………....…12

8.1塑料模零件组装....................................................................................................13

8.2装配调试的工艺要求及注意问题........................................................................13

参考文献……………………...……………………………………………………………….14

我所学习的专业是模具设计与制造专业,这次的毕业设计是线圈骨架产品造型与塑料模具设计。该设计结合大学三年来所学习的专业知识和CAD软件所设计出的一套塑料模。

本文首先简要的概述了塑料模在社会领域中的作用及其以后的发展方向,点明模具设计的重要意义。然后依据工件图进行工艺性分析,进而确定了设计方案,计算出模具工作部分的尺寸,设计出工作零部件;然后依据设计要求选择出各个标准零部件,然后设计出模具的总装配图。在设计中,最重要的就是设计方案的确定、坯料的计算和工作零部件的设计,这是设计的关键,这些设计的正确与否直接关系到成本的高低和设计模具能否正常工作;在设计的最后,总结了自己的心得和体会,并对我的指导老师表示感谢。

通过次毕业设计使我不仅掌握了塑料模具设计的一般流程,更学习到了好多课本上没有学习到的知识,使我受益非浅。

关键词:模具设计与制造、CAD软件、工艺性分析。

Abstract

knowledge of study and a set of plastic moulds that CAD software designed over the past three years of university.

This text the brief plastic role in social field of mould of summary and developing direction afterwards at first, point out in the important meaning of mold design. Then carry on the craft to analyse according to the work piece picture , and then has confirmed the design plan , calculate out mould work some size , design the job spare part; Then choose each standard spare part according to the designing requirement , then design the total installation diagram of the mould . In the design, the important one is sureness , calculation of the blank and design of the job spare part of the design plan the most, this is the key to designing, whether these ones that are designed involve directly or not correctly whether the level of the cost and design mould could work normally; At the end that is designed , have summarized one's own gains and experience , and express thanks for my counselor.

Make me not merely grasp the general procedure of plastic mold design through graduation project once, study to the knowledge not learning to get on many textbooks even more, benefit me a great deal.

Keyword: Mold design and making , CAD software , craft analysis.

第1章 注塑模结构与设计……………………………… …………………………….5

1.1 塑件的工艺型分析.............................................................................................5

1.2计算塑件的体积和质量......................................................................................6

1.3 塑件注塑工艺参数的确定..............................................................................6

第2章 注塑模结构设计.......................................................................................6

2.1:分型面选择...........................................................................................................6

2.2 确定型腔的排列方式.............................................................................................7

2.3浇注系统设计..........................................................................................................7

2.4 抽芯机构设计......................................................................................................8

第3章 模具的有关计算………………………………………………………………...10

第4章模具加热和冷却系统的计算………………………………………………..11

第5章模具闭合高度的确定……………………………………………………..……12

第6章注塑机有关参数的校核………..................…………………………………12

第7章绘制模具总装图………………………………………………………………….12

第8章模具的装配与调试…………………………………………………....…12

8.1塑料模零件组装....................................................................................................13

8.2装配调试的工艺要求及注意问题........................................................................13

参考文献……………………...……………………………………………………………….14