设计简介

摘要

分析了香水盖外壳塑件的结构特点,叙述了该塑件成型工艺、注射模的结构和工作原理,其原理是:采用定距螺钉和弹簧进行二次分型,用斜导柱外侧抽芯,型芯顶出零件,进料时采用潜伏式浇口进料形式,当开模的时候,用球头拉料杆把浇注系统凝料顶出,然后利用型芯内抽推板推出塑件,合模时用弹簧先复位,然后进行下一次成型开始。提高了生产效率。

关键词:香水盖;注射模;定距螺钉;弹簧;斜导柱;侧抽芯;型芯;球头拉料杆;推板

Keyword:perfume cover;inject a mold;certainly be apart from bolt;spring coil; inclined to lead pillar;the side takes out heart;type heart;the ball head pulls to anticipate a pole;push plank

目 录

前言…………………………………………………………2

摘要…………………………………………………………4

设计题目和任务书………………………………………..5

绪论…………………………………………………………6

一、塑件工艺分析………………………………………..16

二、注射机型号的确定………………………………….19

三、注射模的结构设计………………………………….20

四、模具设计的有关计算……………………………….31

五、注射机有关工艺参数的校核………………………37

六、绘制模具总装配图和非标准零件工作图………..43

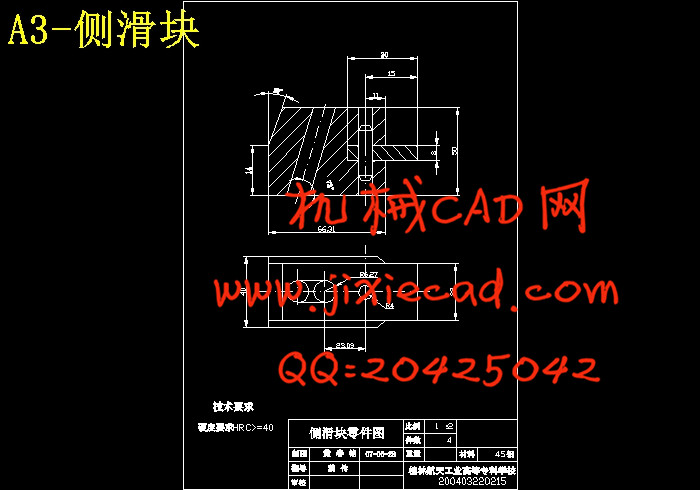

七、注射模主要零件加工工艺规程的编制…………..44

八、设计小结……………………………………………..44

谢辞…………………………………………………………45

参考文献……………………………………………………46

分析了香水盖外壳塑件的结构特点,叙述了该塑件成型工艺、注射模的结构和工作原理,其原理是:采用定距螺钉和弹簧进行二次分型,用斜导柱外侧抽芯,型芯顶出零件,进料时采用潜伏式浇口进料形式,当开模的时候,用球头拉料杆把浇注系统凝料顶出,然后利用型芯内抽推板推出塑件,合模时用弹簧先复位,然后进行下一次成型开始。提高了生产效率。

关键词:香水盖;注射模;定距螺钉;弹簧;斜导柱;侧抽芯;型芯;球头拉料杆;推板

Abstract

Analyzed the structure characteristics of the perfume cover outer shell plastics piece, described the piece’s structure and work principle which model a craft and inject a mold, its principle :adopt and certainly be apart from bolt and spring coil and carry on two cents type, use inclined lead a side outside the pillar and take out heart, type the heart crest spare parts, while entering and anticipating adoption incubate the type sprinkle into anticipate a form, while opening a mold, with the ball head pull and anticipate a pole sprinkle and note system and anticipate, then make use of and take out and push plank and release a plastics piece inside a heart,use spring coil and reset first while matching a mold, then carry on willing model a beginning next time.Raised to produce an efficiency.Keyword:perfume cover;inject a mold;certainly be apart from bolt;spring coil; inclined to lead pillar;the side takes out heart;type heart;the ball head pulls to anticipate a pole;push plank

目 录

前言…………………………………………………………2

摘要…………………………………………………………4

设计题目和任务书………………………………………..5

绪论…………………………………………………………6

一、塑件工艺分析………………………………………..16

二、注射机型号的确定………………………………….19

三、注射模的结构设计………………………………….20

四、模具设计的有关计算……………………………….31

五、注射机有关工艺参数的校核………………………37

六、绘制模具总装配图和非标准零件工作图………..43

七、注射模主要零件加工工艺规程的编制…………..44

八、设计小结……………………………………………..44

谢辞…………………………………………………………45

参考文献……………………………………………………46