设计简介

摘要

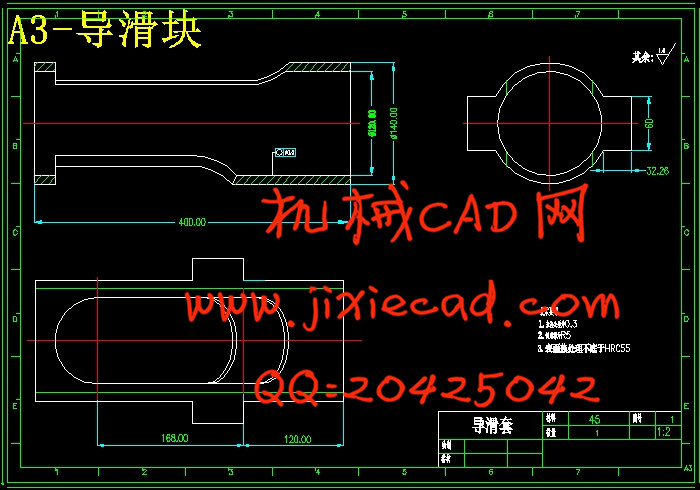

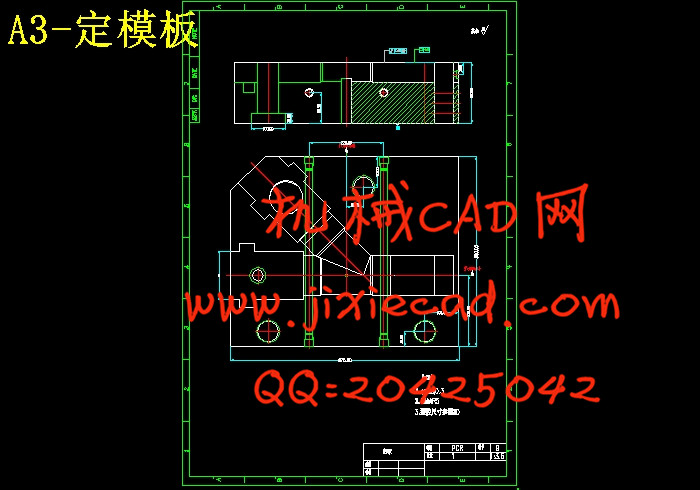

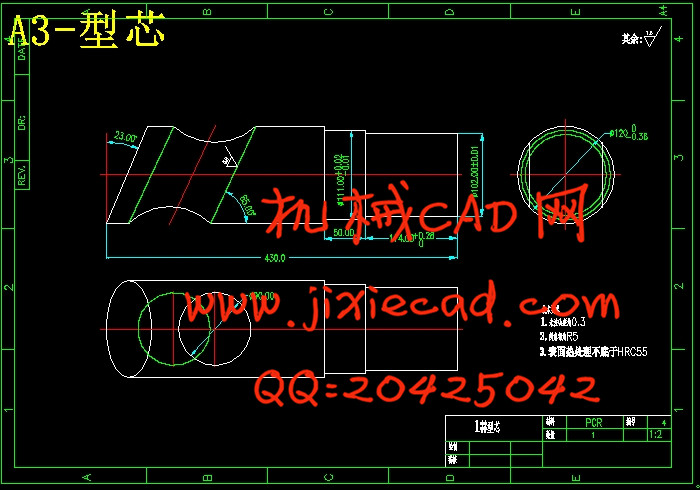

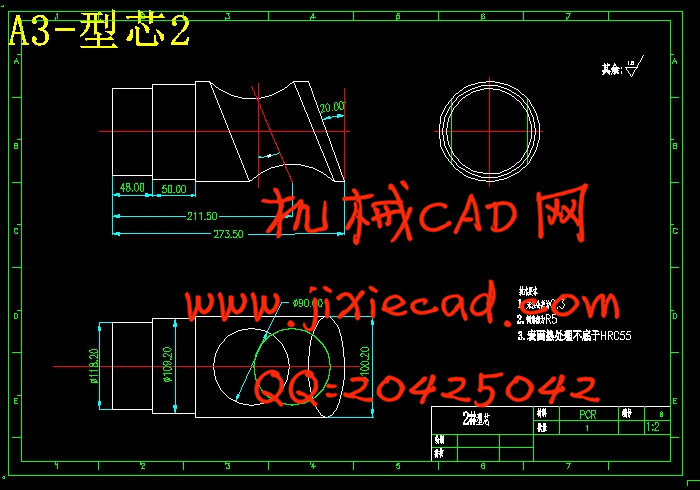

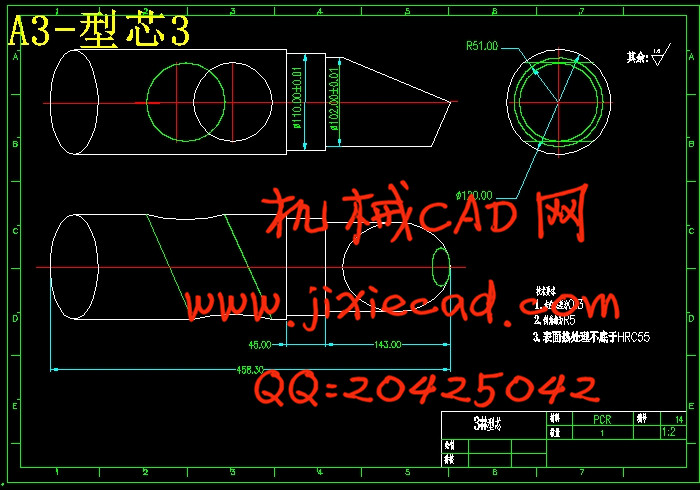

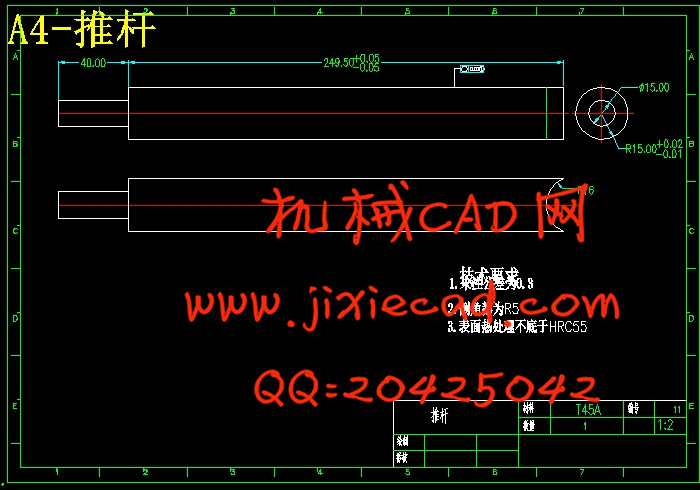

本设计的成品为一下水道用的斜三通管子,在设计过程中按以下步骤设计模具:斜三通注塑模工艺规程的编制—注塑模的结构设计—模具设计的有关计算—模具加热与冷却系统设计—模具闭合高度的确定—注塑机有关参数的校核,最后是绘制模具总装配图。在注塑模艺规程的编制的过程中,要着重分析制品原材料(UPVC)的各项成型工艺参数;在模具结构设计中应注意的是斜导杆起成型兼顶出的作用;模具设计计算的要点是型腔与型芯径向尺寸及深度方向尺寸的计算,型腔与型芯的计算在整个设计过程中显得尤为重要,因为它们直接关系到制品的尺寸精度;模具总装图和非标准零件图用AutoCAD画出,图中需标注的各项参数如尺寸,公差,技术要求,图纸布局等均应按国家标准设计。设计中出现的标准件如推板,螺钉等的零件图无需一一画出,但应参照文献查出其具体结构尺寸。

关键词:斜三通,工艺规程,AutoCAD,国家标准

Abstract

The finished product of this design for a the thin wall box cover, at design to press in the process following step design molding tool:A cover notes the establishment of the Plastics mold craft rules distance- note the structure design- molding tool design of mold of Plastics relevant calculation- the molding tool heats to design with cooling system- the molding tool shuts to match height really settle- note the pit in the machine of Plastics school concerning parameter, finally is to draw the total assemble diagram of molding tool.In the process of note establishment of the Plastics mold skill rules distance, the heavy analysis of important step products each item of the original material( HDPE) to model the craft parameter;In the molding tool structure design should what to notice is inclined to lead the pole to rise to model and the function of the a;The molding tool designs the calculation that the calculating important point is a Cave mold and a Plastics paths toward size and the depth direction size, a Cave mold and the calculation of a Plastics seem to be as importance in the whole design process, because the size accuracy that they relate to the ware directly;The molding tool is total to pack the diagram and not standard spare parts diagrams to draw with the AutoCAD, various parameters,such as size, business trip, that need to be marks in the diagram, technique request, the diagram paper layout etc. all should press national standard design.Design the standard piece of medium emergence if push the plank, the bolt spare parts diagram of etc. did not need 11 draw, but should according to the cultural heritage to look up it concrete structure size.

Keyword:A cover, the craft rules distance, AutoCAD, national standard

第1章 斜三通注塑模工艺规程的编制

1.1原始资料分析﹕…………………………………………….5

1.2塑件的原材料分析………………………………………….6

第2章 注塑模的结构设计………………………7

2.1确定型腔的数量及排列方式………………………….........8

2.2注塑机有关参数的校核……………………………….........8

2.3分型面选择设计…………………………………………….9

2.4排气结构设计………………………………………………11

第3章 模具成型零件结构设计及计算

3.1成型零部件的结构设计…………………………………...12

3.2型腔与型芯工作尺寸的计算……………………………...12

第4章四大系统的设计与计算

4.1抽芯机构设计……………………………………..13

4.2脱模顶出机构设计……………………………………….15

4.3模具加热与冷却系统的设计…………………………….17

第5章 其它零件的选用……………………….18

第6章 模具闭合高度及有关参数校核………...19

6.1 标准模架的选择……………………………….19

第7章 塑料模具的装配………………………...20

本设计的成品为一下水道用的斜三通管子,在设计过程中按以下步骤设计模具:斜三通注塑模工艺规程的编制—注塑模的结构设计—模具设计的有关计算—模具加热与冷却系统设计—模具闭合高度的确定—注塑机有关参数的校核,最后是绘制模具总装配图。在注塑模艺规程的编制的过程中,要着重分析制品原材料(UPVC)的各项成型工艺参数;在模具结构设计中应注意的是斜导杆起成型兼顶出的作用;模具设计计算的要点是型腔与型芯径向尺寸及深度方向尺寸的计算,型腔与型芯的计算在整个设计过程中显得尤为重要,因为它们直接关系到制品的尺寸精度;模具总装图和非标准零件图用AutoCAD画出,图中需标注的各项参数如尺寸,公差,技术要求,图纸布局等均应按国家标准设计。设计中出现的标准件如推板,螺钉等的零件图无需一一画出,但应参照文献查出其具体结构尺寸。

关键词:斜三通,工艺规程,AutoCAD,国家标准

Abstract

The finished product of this design for a the thin wall box cover, at design to press in the process following step design molding tool:A cover notes the establishment of the Plastics mold craft rules distance- note the structure design- molding tool design of mold of Plastics relevant calculation- the molding tool heats to design with cooling system- the molding tool shuts to match height really settle- note the pit in the machine of Plastics school concerning parameter, finally is to draw the total assemble diagram of molding tool.In the process of note establishment of the Plastics mold skill rules distance, the heavy analysis of important step products each item of the original material( HDPE) to model the craft parameter;In the molding tool structure design should what to notice is inclined to lead the pole to rise to model and the function of the a;The molding tool designs the calculation that the calculating important point is a Cave mold and a Plastics paths toward size and the depth direction size, a Cave mold and the calculation of a Plastics seem to be as importance in the whole design process, because the size accuracy that they relate to the ware directly;The molding tool is total to pack the diagram and not standard spare parts diagrams to draw with the AutoCAD, various parameters,such as size, business trip, that need to be marks in the diagram, technique request, the diagram paper layout etc. all should press national standard design.Design the standard piece of medium emergence if push the plank, the bolt spare parts diagram of etc. did not need 11 draw, but should according to the cultural heritage to look up it concrete structure size.

Keyword:A cover, the craft rules distance, AutoCAD, national standard

第1章 斜三通注塑模工艺规程的编制

1.1原始资料分析﹕…………………………………………….5

1.2塑件的原材料分析………………………………………….6

第2章 注塑模的结构设计………………………7

2.1确定型腔的数量及排列方式………………………….........8

2.2注塑机有关参数的校核……………………………….........8

2.3分型面选择设计…………………………………………….9

2.4排气结构设计………………………………………………11

第3章 模具成型零件结构设计及计算

3.1成型零部件的结构设计…………………………………...12

3.2型腔与型芯工作尺寸的计算……………………………...12

第4章四大系统的设计与计算

4.1抽芯机构设计……………………………………..13

4.2脱模顶出机构设计……………………………………….15

4.3模具加热与冷却系统的设计…………………………….17

第5章 其它零件的选用……………………….18

第6章 模具闭合高度及有关参数校核………...19

6.1 标准模架的选择……………………………….19

第7章 塑料模具的装配………………………...20