设计简介

本文根据工程实际的需要完成旋钮的注射模的设计。在设计中采用了聚苯乙烯塑料注射成型,成型方式为一模两腔,该文具体分析了产品的工艺性,确定了所采用塑料的工艺参数和采用的成型设备,确定了模具制作的总体方案,分析并解决了模具的总体结构和各工作部分的具体结构,并进行了一些必要的尺寸计算和强度校核,该论文还对分型面、浇注系统、脱模机构核温度调节系统进行了分析设计,完成了模具的工程图设计,最后进行了主要零件加工工艺设计。

关键词 注射模成型 工艺设计 工程设计

Abstract

The plastic injection mould of c strainer based on practical engineering was designed. In the design the plastic injected and formed with ps, and there were two cavities in the mould. The technology of manufacture particularly was analyzed. The technology parameter of the plastic, the forming method, forming equipment in the course of using the mould and the collectivity blue print of mould design were confirmed. The collectivity structure of the mould and particular structure of all the work section were analyzed and resolved. Especially, side-loosing core and constitute cores structure, conducts some necessary dimension calculate and intension inspect were adopted. The irrigate system、shuck institution and temperature adjust system were also designed. The schedule drawings of the mould were done. Final process cards of most parts were designed, and all the work of the mould design was finished.

Keywords Plastic injection mould Forming Process design Engineering design

目 录

1 引言(或绪论)………………………………………………………………… 1

1.1塑料模具的现状及发展 ………………………………………………………… 1

1.2塑料注射模具的设计步骤 ……………………………………………………… 4

1.3毕业设计课程任务要求 ………………………………………………………… 6

2 方案分析与设计 ………………………………………………………………… 7

3 旋钮零件注射模的详细设计 ……………………………………………… 8

3.1塑料注射成型机的选择 ……………………………………………………………8

3.2注射模具分型面的选择……………………………………………………………12

3.3注射模具浇注系统的设计…………………………………………………………13

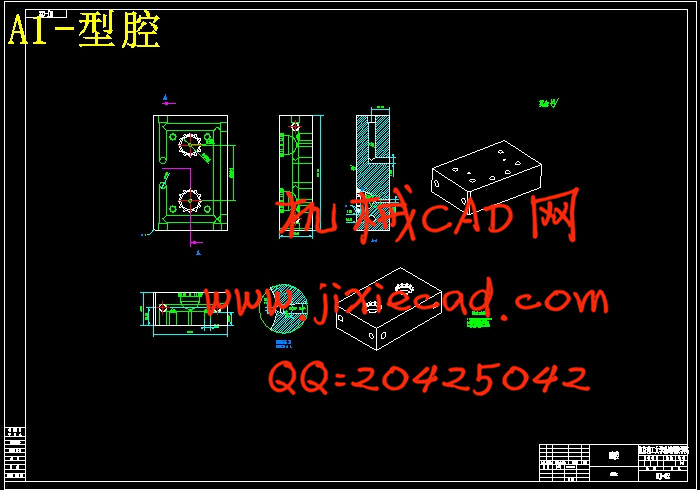

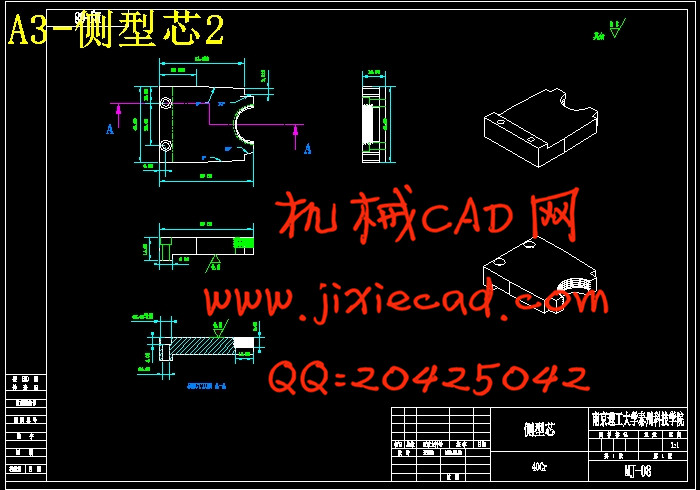

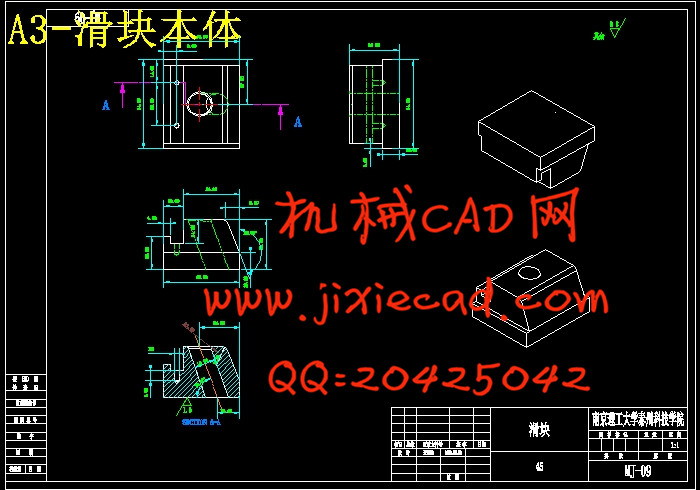

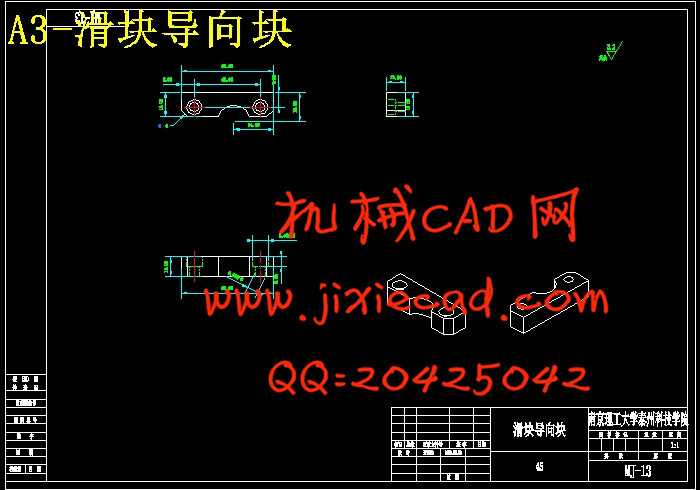

3.4注射模具成型零件的模体设计 …………………………………………………19

3.5注射模具的顶出机构的设计 ……………………………………………………23

3.6塑料注射模具的温度调节系统设计 ……………………………………………24

3.7模具结构设计 ……………………………………………………………………26

4注射模加工工艺设计 ………………………………………………………………27

4.1坯料确定 …………………………………………………………………………27

4.2模板的平面加工 …………………………………………………………………27

4.3塑料注射模具型腔常用加工方法及设备 ………………………………………27

结束语 ……………………………………………………………………………… 29

致谢 ………………………………………………………………………………… 30

参考文献………………………………………………………………………………31

关键词 注射模成型 工艺设计 工程设计

Abstract

The plastic injection mould of c strainer based on practical engineering was designed. In the design the plastic injected and formed with ps, and there were two cavities in the mould. The technology of manufacture particularly was analyzed. The technology parameter of the plastic, the forming method, forming equipment in the course of using the mould and the collectivity blue print of mould design were confirmed. The collectivity structure of the mould and particular structure of all the work section were analyzed and resolved. Especially, side-loosing core and constitute cores structure, conducts some necessary dimension calculate and intension inspect were adopted. The irrigate system、shuck institution and temperature adjust system were also designed. The schedule drawings of the mould were done. Final process cards of most parts were designed, and all the work of the mould design was finished.

Keywords Plastic injection mould Forming Process design Engineering design

目 录

1 引言(或绪论)………………………………………………………………… 1

1.1塑料模具的现状及发展 ………………………………………………………… 1

1.2塑料注射模具的设计步骤 ……………………………………………………… 4

1.3毕业设计课程任务要求 ………………………………………………………… 6

2 方案分析与设计 ………………………………………………………………… 7

3 旋钮零件注射模的详细设计 ……………………………………………… 8

3.1塑料注射成型机的选择 ……………………………………………………………8

3.2注射模具分型面的选择……………………………………………………………12

3.3注射模具浇注系统的设计…………………………………………………………13

3.4注射模具成型零件的模体设计 …………………………………………………19

3.5注射模具的顶出机构的设计 ……………………………………………………23

3.6塑料注射模具的温度调节系统设计 ……………………………………………24

3.7模具结构设计 ……………………………………………………………………26

4注射模加工工艺设计 ………………………………………………………………27

4.1坯料确定 …………………………………………………………………………27

4.2模板的平面加工 …………………………………………………………………27

4.3塑料注射模具型腔常用加工方法及设备 ………………………………………27

结束语 ……………………………………………………………………………… 29

致谢 ………………………………………………………………………………… 30

参考文献………………………………………………………………………………31