设计简介

摘 要

本设计的题目是旋钮注塑模设计,通过塑件的工艺分析、注塑模结构设计及有关计算、模具闭合高的的确定、注塑机有关参数的校核等,该模具基本符合要求。

该塑件要求表面没有毛刺、凹陷等缺陷,内部不得有导电杂质,没有其它特别要求,故注塑较易实现。根据塑件的成型要求及模腔的排列方式,选用侧浇口比较合适,设计时,考虑选择从壁厚3mm处进料,料从厚处向薄处流,且该模具型芯采用组合式结构,有利于填充、排气。

凸模主要是成形制件的内表面,考虑加工的难易程度和材料的价值利用、塑件的形状和尺寸,并考虑到塑件的生产率,本模具采用一模四件的结构形式;凹模主要成型塑件外表面,结构较简单,将凹模设计成组合式结构,既保证塑件外观与质量,模具加工也比较方便。

由于设计者的能力有限,设计中存在很多不足之处,还望老师给予指教和谅解。

关键词:塑件表面、组合式型腔、侧浇口。

The topic of this design is a knob to note

Abstract

The topic of this design is a knob to note the mold of part designs, the piece of part craft analysis, and the mold construction design and relevant calculation, the molding tool shuts to match high really settle, note the machine of the concerning parameter etc., that molding tool is basic to meet the request.

The part's piece requests the surface has no the hair stabs, hollow etc. blemish, inner part cannot conduct electricity the miscellaneous quality, have no other special request, so note the part than realizes easily.According to an alignment for modeling request and moldings method, choose to sprinkle with the side comparison accommodation, design, consider the choice from the wall the thick 3 mms enters to anticipate, anticipate to flow to thin place from the thick place, and the molding tool's type 芯 adopts the sectional construction, benefitting to fill , row spirit.

The convex mold is a difficult easy degree to take shape a the piece of system inside surfaces, consider to process primarily with the material of worth a make use of, a rate of production for of shape with size, combining in consideration of the piece of the part , this molding tool adoption is sectional to model a mold six pieces constructions form;The cave mold models the part an outward appearance primarily, construction than simple, design the cave mold sectional construction, since guarantee the part an external appearance and quantity, the molding tool processes too more convenient.

Because design of ability limited, design inside exsit a lot of not enough places, still hope the teacher gives to advise with understand.

Key phrase:The part have sixe, molding sectional types , sides sprinkle.

目 录

绪论……………………………………………………………………………… 1

第一章 任务来源及设计目的意义…………………………………………… 3

1.1 设计任务来源………………………………………………………… 3

1.2 设计目的及意义……………………………………………………… 3

1.3 塑料注塑模的特点、要求…………………………………………… 3

第二章 模塑工艺规程的编制…………………………………………………… 4

2.1塑件的工艺分析………………………………………………………… 4

2.2计算塑件的体积与质量………………………………………………… 5

2.3塑件注塑工艺参数的确定……………………………………………… 6

第三章 注塑模结构设计………………………………………………………… 7

3.1分型面的选择………………………………………………………… 7

3.2确定塑件型腔的排列方式…………………………………………… 7

3.3 浇注系统……………………………………………………………… 8

3.4 成型零件的结构设计………………………………………………… 9

第四章 模具设计的有关计算…………………………………………………… 11

4.1 型腔、型芯工作尺寸的计算………………………………………… 11

4.2 腔侧壁厚度、底板厚度计算………………………………………… 11

第五章 模具闭合高度的确定…………………………………………………… 13

第六章 注塑机有关参数的校核………………………………………………… 14

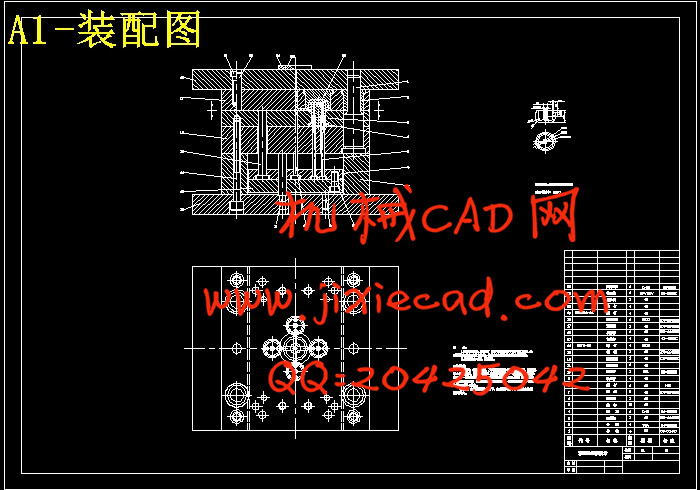

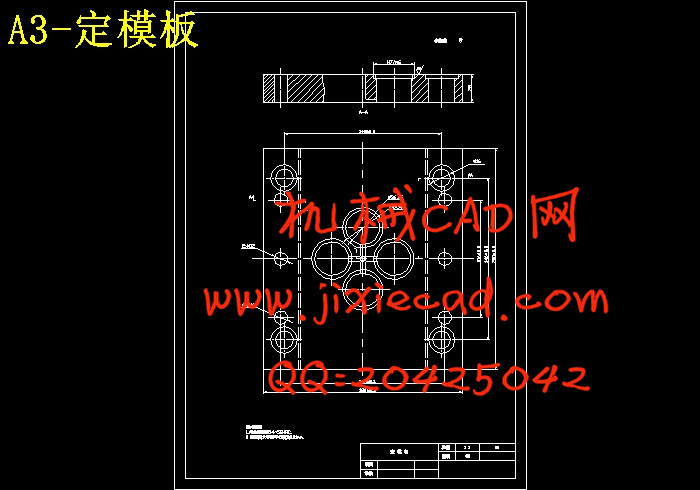

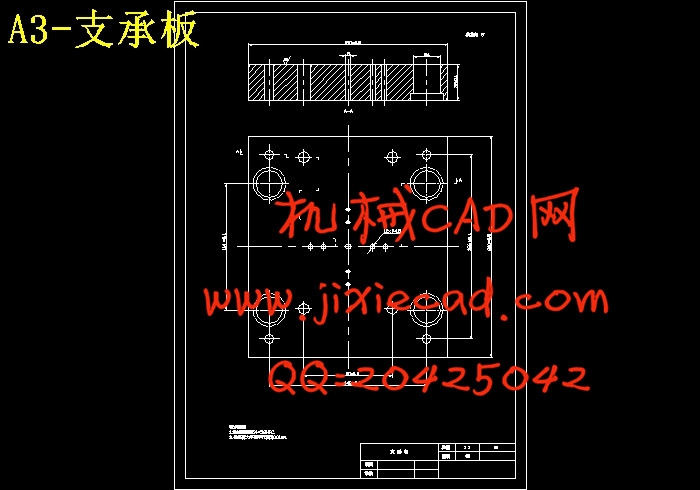

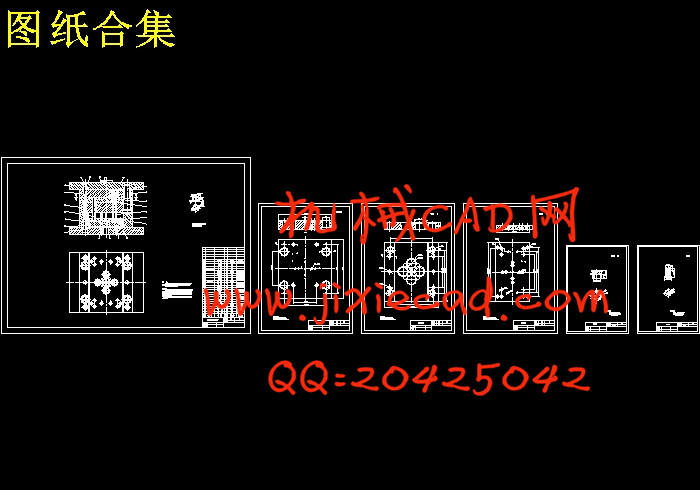

第七章 绘制模具总装图和非标准件工作图…………………………………… 15

第八章 注塑机主要零件加工工艺规程的编制………………………………… 16

8.1 凹模的加工工艺过程……………………………………………………16

8.2凸模的加工工艺过程…………………………………………………… 18

第九章 模具装配………………………………………………………………… 20

9.1 模具安装………………………………………………………………… 20

9.2 试模……………………………………………………………………… 20

设计总结…………………………………………………………………………… 24

致谢………………………………………………………………………………… 25

参考文献…………………………………………………………………………… 26

本设计的题目是旋钮注塑模设计,通过塑件的工艺分析、注塑模结构设计及有关计算、模具闭合高的的确定、注塑机有关参数的校核等,该模具基本符合要求。

该塑件要求表面没有毛刺、凹陷等缺陷,内部不得有导电杂质,没有其它特别要求,故注塑较易实现。根据塑件的成型要求及模腔的排列方式,选用侧浇口比较合适,设计时,考虑选择从壁厚3mm处进料,料从厚处向薄处流,且该模具型芯采用组合式结构,有利于填充、排气。

凸模主要是成形制件的内表面,考虑加工的难易程度和材料的价值利用、塑件的形状和尺寸,并考虑到塑件的生产率,本模具采用一模四件的结构形式;凹模主要成型塑件外表面,结构较简单,将凹模设计成组合式结构,既保证塑件外观与质量,模具加工也比较方便。

由于设计者的能力有限,设计中存在很多不足之处,还望老师给予指教和谅解。

关键词:塑件表面、组合式型腔、侧浇口。

The topic of this design is a knob to note

Abstract

The topic of this design is a knob to note the mold of part designs, the piece of part craft analysis, and the mold construction design and relevant calculation, the molding tool shuts to match high really settle, note the machine of the concerning parameter etc., that molding tool is basic to meet the request.

The part's piece requests the surface has no the hair stabs, hollow etc. blemish, inner part cannot conduct electricity the miscellaneous quality, have no other special request, so note the part than realizes easily.According to an alignment for modeling request and moldings method, choose to sprinkle with the side comparison accommodation, design, consider the choice from the wall the thick 3 mms enters to anticipate, anticipate to flow to thin place from the thick place, and the molding tool's type 芯 adopts the sectional construction, benefitting to fill , row spirit.

The convex mold is a difficult easy degree to take shape a the piece of system inside surfaces, consider to process primarily with the material of worth a make use of, a rate of production for of shape with size, combining in consideration of the piece of the part , this molding tool adoption is sectional to model a mold six pieces constructions form;The cave mold models the part an outward appearance primarily, construction than simple, design the cave mold sectional construction, since guarantee the part an external appearance and quantity, the molding tool processes too more convenient.

Because design of ability limited, design inside exsit a lot of not enough places, still hope the teacher gives to advise with understand.

Key phrase:The part have sixe, molding sectional types , sides sprinkle.

目 录

绪论……………………………………………………………………………… 1

第一章 任务来源及设计目的意义…………………………………………… 3

1.1 设计任务来源………………………………………………………… 3

1.2 设计目的及意义……………………………………………………… 3

1.3 塑料注塑模的特点、要求…………………………………………… 3

第二章 模塑工艺规程的编制…………………………………………………… 4

2.1塑件的工艺分析………………………………………………………… 4

2.2计算塑件的体积与质量………………………………………………… 5

2.3塑件注塑工艺参数的确定……………………………………………… 6

第三章 注塑模结构设计………………………………………………………… 7

3.1分型面的选择………………………………………………………… 7

3.2确定塑件型腔的排列方式…………………………………………… 7

3.3 浇注系统……………………………………………………………… 8

3.4 成型零件的结构设计………………………………………………… 9

第四章 模具设计的有关计算…………………………………………………… 11

4.1 型腔、型芯工作尺寸的计算………………………………………… 11

4.2 腔侧壁厚度、底板厚度计算………………………………………… 11

第五章 模具闭合高度的确定…………………………………………………… 13

第六章 注塑机有关参数的校核………………………………………………… 14

第七章 绘制模具总装图和非标准件工作图…………………………………… 15

第八章 注塑机主要零件加工工艺规程的编制………………………………… 16

8.1 凹模的加工工艺过程……………………………………………………16

8.2凸模的加工工艺过程…………………………………………………… 18

第九章 模具装配………………………………………………………………… 20

9.1 模具安装………………………………………………………………… 20

9.2 试模……………………………………………………………………… 20

设计总结…………………………………………………………………………… 24

致谢………………………………………………………………………………… 25

参考文献…………………………………………………………………………… 26