设计简介

摘要

我设计是材质ABS仪表外壳的设计,其中引用了若干文件时,主要考虑的ABS材料的过程中,需要引进的ABS成型条件,模具的基本结构,塑料件,塑料件制造方面的考虑问题,模具的成形工艺分析,腔体设计和布局方法,其重点是主要道路,剥离的设计,滑盖设计,滑盖设计参数,设计考虑,浇注系统,冷却系统的基本结构,采暖系统,腔体设计图纸,模具选择参数,计算设计和结构设计参数占浇口设计简单浇口,浇口设计考虑浇口、浇口设计、模具设计、剥离的释放原理的结构设计引入一个设计版本考虑,在生产过程中应注意事项,和制造的结构特点,通过塑料部件分析和比较的过程中,注射模具的最终设计。结构塑料件的过程中,从模具结构开始的主题,校对的结构成型的注塑机的选择以及相关的参数的一部分,都有详细的说明,以及塑料部件的制备方法。这表明利用整个设计过程中可以实现这个塑料模具开发工艺。根据在根据本主题的设计要求是仪表壳模设计。这是设计生产出注塑模具产品仪表外壳,它可以提高产量。

作为中国工业发展需要,ABS产品在工业,农业和家庭应用的各个领域是质地非常广泛,非常高的要求,技术也非常高,在生产塑料制品,高品质的模具设计,良好的模具设备,适当的技术,这是模制塑料件优秀条件优秀,高效的模具材料成型设备,模具是工业生产必不可少的设备,是中国经济的基础设施,是一个国家的主要产业发展迹象的措施。因此,模具生产已经在生产和生活非常重要的作用。

ABS具有正因为如此在应用领域有其广泛的足迹良好的整体性能和良好的成形性。 ABS材料是21世纪40年代和50年代开发的一种热塑性塑料机械,是塑料材料的一个非常良好的机械性能,不仅具有良好的刚性,硬度和良好的流动性,而且还具有高韧性的特点,可注塑,挤出或热成型塑料件。许多汽车部件由注射模塑法制造,冲击效果,声音效果,抗刮效果的ABS树脂的优点,耐热性非常好,比聚丙烯更美观,尤其是冲击效果和温度的要求更高的部分。除了聚氨酯和聚丙烯外ABS材料具有很高的地位。通常的汽车用外壳,方向盘位置,导向管和把手和按钮的ABS的这些小部件的应用程序。 ABS的加工容易,尺寸稳定性和表面光泽度的影响,以良好的效果,所以它不仅能确定该涂层的性能,但也可喷金属和焊接和粘接该二次加工,广泛的电子产品的领域,其中包括办公和消费电器,办公用品主要包括处理器,办公用具。如今在电子市场,在要求阻燃和电子电器市场的高热量还是不可缺少的,火焰,耐热ABS树脂具有较大的优势和其他工程塑料合金的竞争。

关键词: 注射模; CAD; 工艺

Abstract

This design is the design of the injection molding material ABS instrument case, in which reference to a number of documents, the main consideration of the ABS material process, requiring the introduction of ABS molding conditions, the basic structure of the mold, plastic parts, plastic parts manufacturing considerations The problem, the basic structure of the mold forming process analysis, cavity design and layout methods.

which focuses on the main road, stripping design, gate design, gate design parameters, design considerations, pouring system, cooling system, heating system , cavity design drawings, mold selection parameters, calculates the design and structural design parameters accounting sprue design brief sprue, sprue design considerations sprue, gate design, mold design, launch structure, stripping The structural design of the release principle to introduce a release design considerations, in the production process should be precautions, and structural characteristics of manufacture, through the plastic parts to analyze and compare the process, the final design of an injection mold. The topics of the process of structural plastic parts, starting from the mold structure, proofreading structures forming part of the injection molding machine selection and related parameters, has a detailed description, and the preparation process of plastic parts. Indicating that the use of the entire design process can achieve this plastic mold developed craft.

According to the design requirements in accordance with the subject is the instrument shell mold design. That is designed to produce a plastic injection mold products instrument shell, which can increase production various fields of industry, agriculture and domestic applications is very broad, very high demands on the texture, technology is quality mold design, good mold equipment, proper technology, excellent and efficient mold material molding equipment which ABS has good overall performance and excellent formability, precisely because of this in the field of application has its wide footprint. ABS material is 21 1940s and 1950s developed a thermoplastic plastic machinery, is a very good mechanical properties of plastic materials, not only has good rigidity, hardness and good mobility, but also has high toughness characteristics, and can be injection molding, extrusion or thermoformed plastic parts. Many auto parts are produced by injection molding method, ABS resin advantages of impact effects, sound effects, anti-scratch effect, heat resistance is very good, more beautiful than the PP, especially the impact effect and temperature requirements more high parts. In addition to polyurethane and polypropylene outer ABS material has a high status. Usually the car with the outside shell, steering wheel position, the guide tubing and handles and buttons These widgets application of ABS. ABS is easily processed, dimensional stability and surface gloss effects to good effect, so it can not only determines the performance of the coating, but also can be sprayed metal and welding and bonding This secondary processing, widely in the area of electronic products, including office and consuming appliances, office appliances mainly contains the processor, office appliances. Now in the electronic market, demands for flame and high heat of electronic appliances market is still indispensable, flame and heat resistant ABS resin has a larger advantage.

Keywords: plastic; CAD; dashboard

第一章制件产品要求 1

第二章ABS材质分析 2

2.1 ABS材质介绍 2

2.2 ABS材质性能 2

2.3 塑件成型性能 2

2.4 材料性能力学性能 3

第三章 成型方法介绍 4

3.1 挤出成型 4

3.2 压延成型 4

3.3 注射成型 4

3.4 吹塑成型 4

3.5 泡沫塑料的成型 5

3.6 确定成型方法 5

第四章注塑机的选用 6

4.1 选用注射机 6

4.2 计算制件的体积和质量 6

4.3 有查阅资料初步确定制件注射成型工艺参数 6

4.4 ABS的工艺参数 7

第五章分型面的确定与浇注系统的设计 8

第六章浇注系统的设计 10

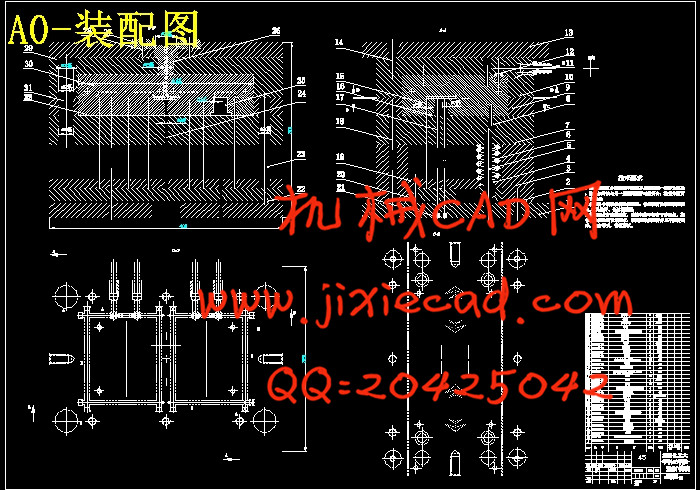

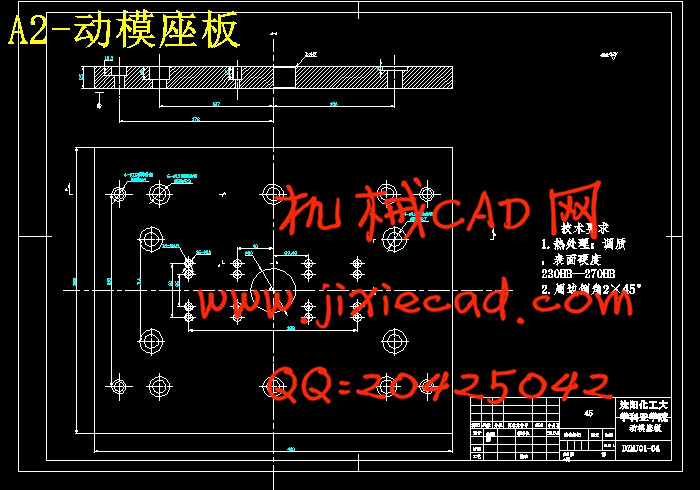

第七章模架的确定和标准模架的选用 11

7.1 模架与模仁的关系 11

7.2 模架部分的参数 11

7.3 选择模架 11

7.4 检验所选模架 11

第八章推出机构的设计 13

8.1 推出机构设计原则 13

8.2 推力计算 13

8.3 推出机构的复位机构 13

8.4 推杆的位置与布局 14

8.5 推出机构方式 14

第九章浇口设计 16

9.1 浇口形式的选择 16

9.2 浇口尺寸的确定 16

第十章冷却系统结构 17

10.1 设计要点 18

10.2 模具加热装置的设计 18

10.3 模具加热装置的类型和计算 18

10.4 模具加热应注意的问题 19

10.5 冷却水体积流量 19

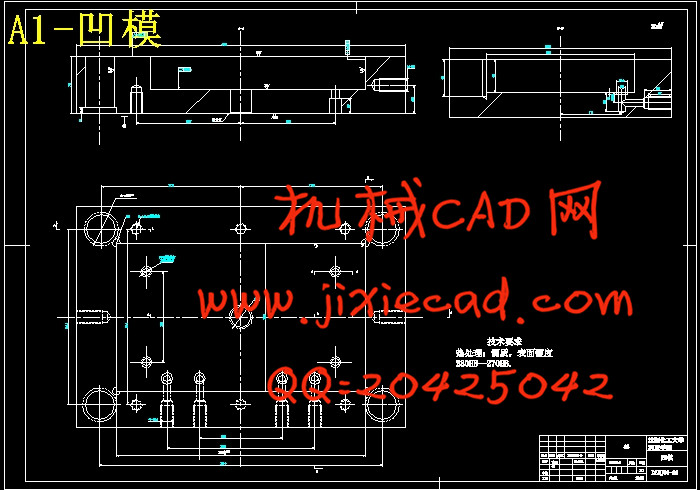

第十一章成型零件结构设计 20

第十二章模具加工 22

12.1 模具加工 22

结论 23

参考文献 24

致谢 25