设计简介

油窗端盖注塑模具设计

摘 要

塑料工业是当今世界上增长最快的工业门类之一,而注塑模具是其中发展较快的种类,因此,研究注塑模具对了解塑料产品的生产过程和提高产品质量有很大意义。注射模技术的不断发展需要越来越多的工艺流程。注射成型过程中最重要的问题是模具的正确设计。

从根本上说,注射模具包括浇口和浇注系统,另一部分是放置顶出系统。模具零件是在分型面被定位的。

注射模具型腔选择等设计计算要求掌握加工材料、注射机和模具等方面的准确知识。模具的制造成本随着型腔数目的增加而增加,而相关的加工费用减少了。一个给定的模具零件的生产周期取决于壁厚、注射速度、收缩率、模内材料的冷却时间、冷却的效能及必要的辅助时间,如压力持续时间、排气时间及延迟时间等。

本设计介绍了注射成型的基本原理,特别是单分型面注射模具的结构与工作原理,对注塑产品提出了基本的设计原则;详细介绍了冷流道注射模具浇注系统、温度调节系统和顶出系统的设计过程,通过本设计,可以对注塑模具有一个初步的认识,注意到设计中的某些细节问题,了解模具结构及工作原理。

关键词:塑料模具,参数化,分型面,浇注系统,模具型腔。

THE PLASTIC INJECT MODLE DESIGN

ABSTRACT

plastic industry is in the world grows now one of quickest industry classes, but casts the mould is development quick type, therefore, the research casts the mold to understand the plastic product the production process and improves the product quality to have the very big significance. The continuing development of injection mold technology demands more and more of the processes. The most important problem in the process of injection molding is undoubtedly the correct design of injection mold .

Basically the injection mold consists of two halves.

One mold half contains the sprue bushing and runner system, the other half houses the ejection system. The molded part is located at the parting line.

To set up a calculation conceiving the choice of cavities in an injection mold requires accurate knowledge of the matrrial to be processed, of the injection-molding machine and of the molds. The mold costs increase with the rising number of cavities and the relative machine costs decrease. The production time required for a given molded part depends on the wall thicknes, the injection speed, the recovery rate, the time required to coll the molded material, the cooling capacity of the mold and the necessary incidental time such as duration of pressure holding time, ejection time, delay time, ect.

This design introduced the injection takes shape the basic principle, specially single is divided the profile to inject the mold the structure and the principle of eork, to cast the product to propose the basic principle of design; Introducted in detail the cold flod channel injection evil spirit mold pours the system, the temperature contral system and goes against the system the design process, and has given the explanation to the mold intensity request; Through this design, may to cast the mold to have a preliminary understanding, notes in the design certain detail question, understands the mold structure and the principle of work; Through to the PROGRAM study, may establish the simple components the components storehouse, thus effective enhancement eorking efficiency.

KEY WORDS: The plastic mold, the parameterization, inlays, divides the profile

目 录摘 要

塑料工业是当今世界上增长最快的工业门类之一,而注塑模具是其中发展较快的种类,因此,研究注塑模具对了解塑料产品的生产过程和提高产品质量有很大意义。注射模技术的不断发展需要越来越多的工艺流程。注射成型过程中最重要的问题是模具的正确设计。

从根本上说,注射模具包括浇口和浇注系统,另一部分是放置顶出系统。模具零件是在分型面被定位的。

注射模具型腔选择等设计计算要求掌握加工材料、注射机和模具等方面的准确知识。模具的制造成本随着型腔数目的增加而增加,而相关的加工费用减少了。一个给定的模具零件的生产周期取决于壁厚、注射速度、收缩率、模内材料的冷却时间、冷却的效能及必要的辅助时间,如压力持续时间、排气时间及延迟时间等。

本设计介绍了注射成型的基本原理,特别是单分型面注射模具的结构与工作原理,对注塑产品提出了基本的设计原则;详细介绍了冷流道注射模具浇注系统、温度调节系统和顶出系统的设计过程,通过本设计,可以对注塑模具有一个初步的认识,注意到设计中的某些细节问题,了解模具结构及工作原理。

关键词:塑料模具,参数化,分型面,浇注系统,模具型腔。

THE PLASTIC INJECT MODLE DESIGN

ABSTRACT

plastic industry is in the world grows now one of quickest industry classes, but casts the mould is development quick type, therefore, the research casts the mold to understand the plastic product the production process and improves the product quality to have the very big significance. The continuing development of injection mold technology demands more and more of the processes. The most important problem in the process of injection molding is undoubtedly the correct design of injection mold .

Basically the injection mold consists of two halves.

One mold half contains the sprue bushing and runner system, the other half houses the ejection system. The molded part is located at the parting line.

To set up a calculation conceiving the choice of cavities in an injection mold requires accurate knowledge of the matrrial to be processed, of the injection-molding machine and of the molds. The mold costs increase with the rising number of cavities and the relative machine costs decrease. The production time required for a given molded part depends on the wall thicknes, the injection speed, the recovery rate, the time required to coll the molded material, the cooling capacity of the mold and the necessary incidental time such as duration of pressure holding time, ejection time, delay time, ect.

This design introduced the injection takes shape the basic principle, specially single is divided the profile to inject the mold the structure and the principle of eork, to cast the product to propose the basic principle of design; Introducted in detail the cold flod channel injection evil spirit mold pours the system, the temperature contral system and goes against the system the design process, and has given the explanation to the mold intensity request; Through this design, may to cast the mold to have a preliminary understanding, notes in the design certain detail question, understands the mold structure and the principle of work; Through to the PROGRAM study, may establish the simple components the components storehouse, thus effective enhancement eorking efficiency.

KEY WORDS: The plastic mold, the parameterization, inlays, divides the profile

前 言 1

第一章:制件的结构与工艺性分析 2

1.1 制件相关信息 2

1.2材料的相关性质 3

1.2.1 基本特性 3

1.2.2 主要用途 3

1.2.3 成型特点 3

1.3塑件的脱模斜度 4

1.4塑件的尺寸精度及表面质量要求 4

第二章:初选注射机 6

2.1 计算塑件体积和最大投影面积 6

2.2 选择压力机 6

2.3 确定型腔数目 7

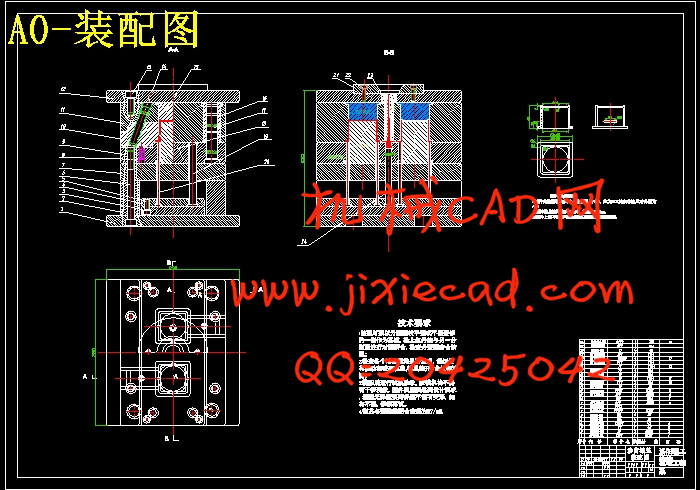

第三章 模具设计 9

3.1 型腔的分布设置 9

3.2 分型面的确定 9

3.3 浇口的确定原则 10

3.4 浇注系统的确定 11

3.4.1 主流道的设计 11

3.4.2 分流道的设计 12

3.4.3 冷料穴的设计 13

3.4.4浇口的相关参数选择 14

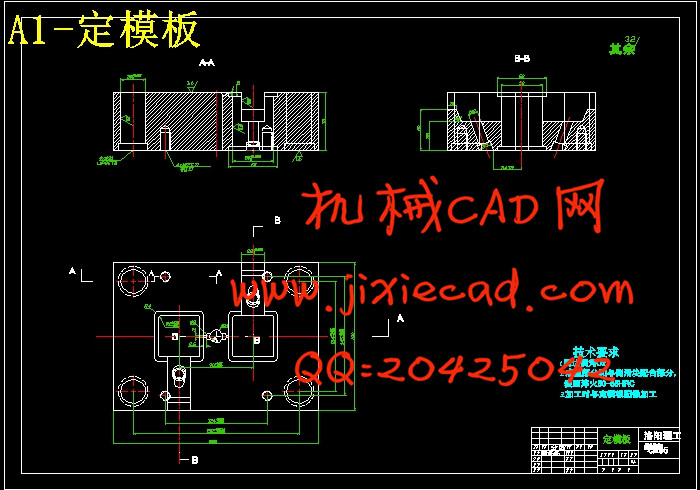

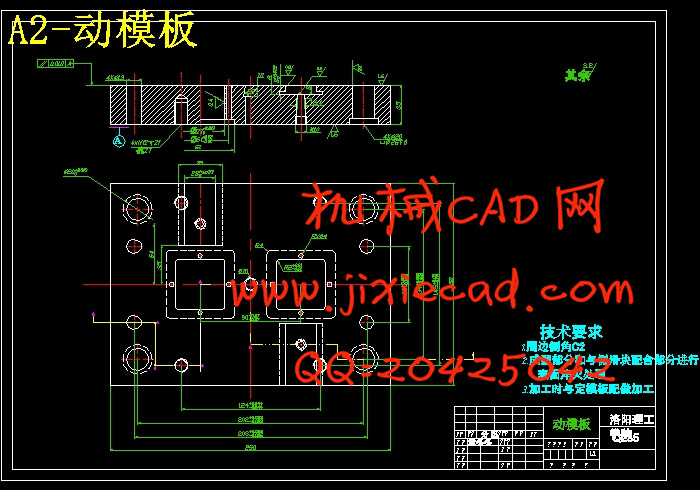

3.5成型零部件的结构设计 14

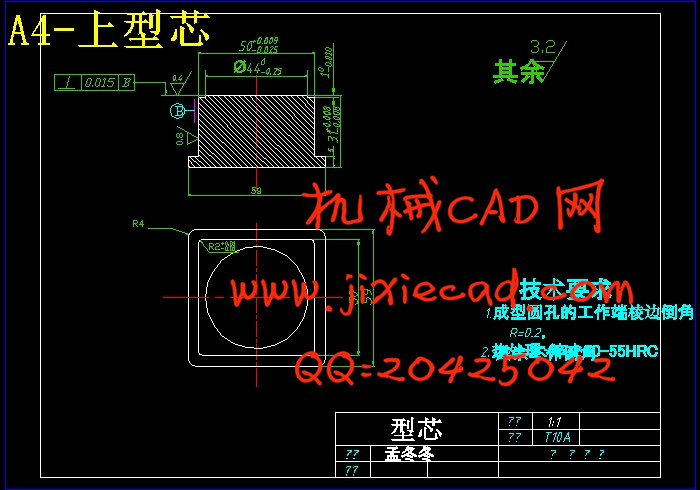

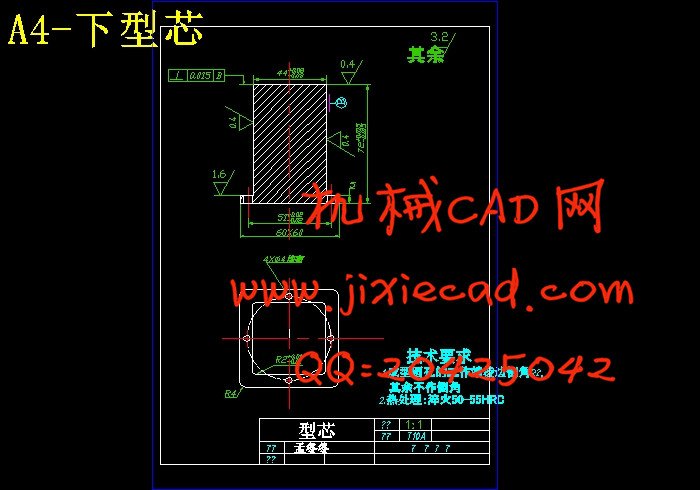

3.5.1 型腔的结构设计 14

3.5.2 型芯的结构设计 15

3.6 模具成型零部件尺寸计算 15

3.5.1 计算成型零部件尺寸要考虑的因素 16

3.5.2 制件尺寸的公差转换 16

3.5.3成型零部件尺寸计算 17

3.7 模架的选用 20

3.7.1 模架型号的确定 20

3.7.2 模架具体尺寸的确定 21

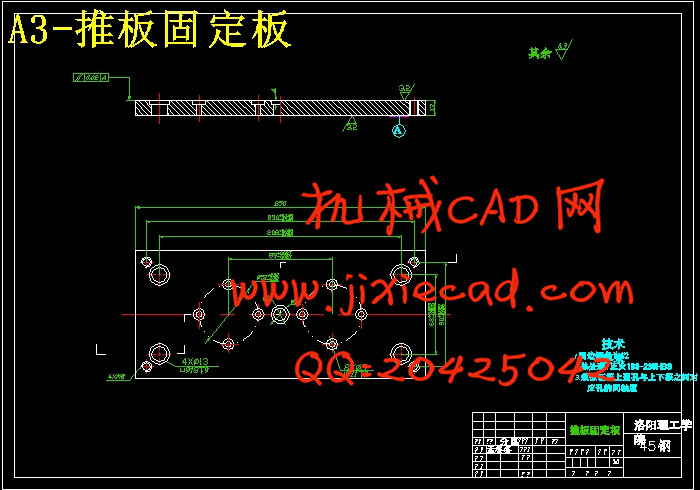

3.8 结构零部件的设计 22

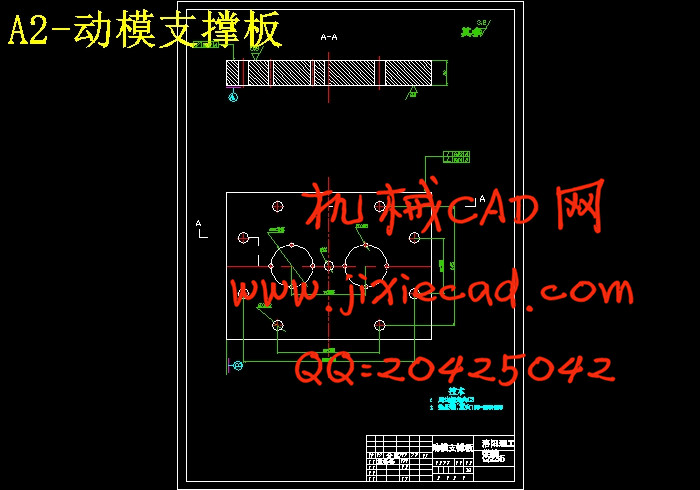

3.8.1 支承板的设计 22

3.8.2 垫块的设计 22

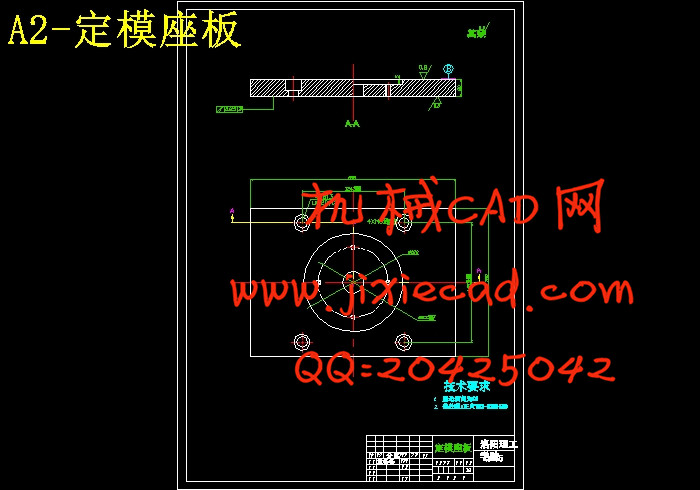

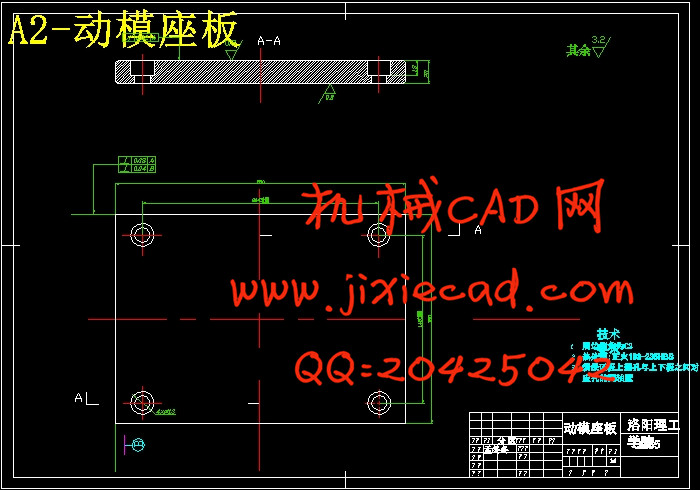

3.8.3 定模座板和动模座板的设计 22

3.8.4 导柱的设计 23

3.8.5 导套的设计 24

3.8.6 设计导柱导套需要注意的事项 24

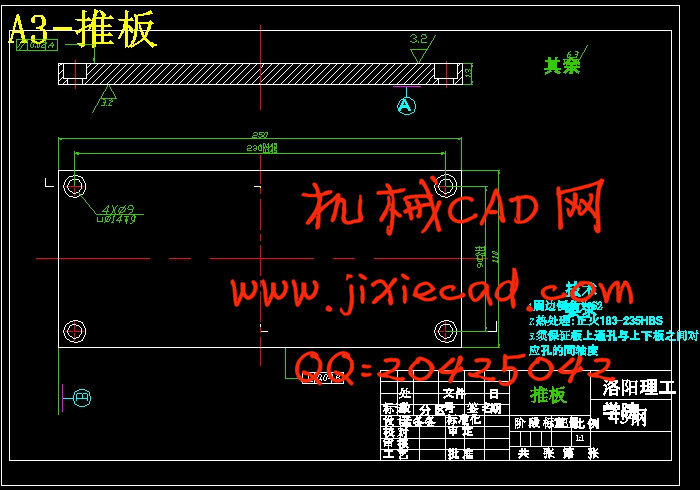

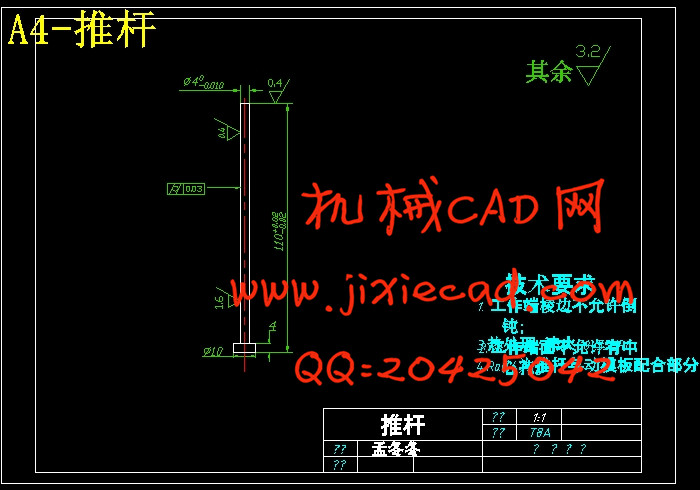

3.9推出机构的设计 24

3.9.1 推杆的设计 25

第四章 冷却系统的设计 28

4.1 冷却水孔直径的确定 28

4.2 冷却水回路的布置原则 28

第五章 注射机的相关校核 29

5.1 注射机额定注射量的校核 29

5.2注射压力的校核 29

5.3锁模力的校核 29

5.4模具安装尺寸的校核 30

5.41喷嘴尺寸校核 30

5.4.2模具厚度校核 30

5.5 开模行程的校核 31

结 论 32

谢 辞 33

参考文献 34