设计简介

(整流罩注射模设计)

[摘要] 根据塑件的结构特点,提出适合整流罩零件注射成型的模具结构和设计了生产该零件的注射模,并详细描述了模具的工作过程。介绍了注射模的设计方案、设计要点和模具设计时应注意的问题,并对浇注系统的设计计算作了较详细的阐述。

根据注射模的结构和设计要求,该注射模采用了一模两件的模具结构和顶管顶出装置。根据注射模和注射机的关系选择注射机和确定塑件的注射工艺参数。注射模的结构设计包括分型面选择、确定型腔的排列方式、浇注系统设计和成型零件结构设计。成型零件结构设计包括凹模的结构设计、凸模的结构设计。

模具结构的简化,降低了模具成本。经生产验证,模具结构稳定,可靠,效果很好,对类似产品的注射模设计有很好的参考价值。

关键词:整流罩, 注塑模,模具结构,浇注系统。

(Design of injection mould for Cowling)

[Abstract] According to the structure characterstic of plastic part .the mould structure adapted to the injection moulding for the part was put forward,and the working process was describled in dectail .the injection mould for forming the part was designed to ensure the products up to the technical requirements .the scheme and main of design of the injection mould for Cowling was introduced ,and the paper presented some points in design that should be paid attention and design calculating was done for the system .

According to the structure of the injection mould and design requirements ,the die structure of two parts of one mould and liftout attachment of ring were adapted .according to the relation of the injection mould and injection molding machine , to select the injection mould machine and ensure the injection processing parameter of the plastic part . the structure of the injection mould consists of choice of mouldjoint ,confirmation of arrangement of impression ,design of the feed system ,design of the structure for moulding part . design of the structure for moulding part consists of the design of structure for die and punch .

The mold structure was predigested, the cost of the mold was evidently decreased. It was concluded from practical experitence that structure of the mold was stable , reliable and efficient . it provides a good reference for the design of injection mold for similar parts .

Key words: cowling , injection mould , mold structure , casting system.

目录

绪论……………………………………………………………1

第一章 模具工艺规程的编制

1.1 塑件的工艺性分析………………………………………………………1

1.2 模具型腔数和注塑机的选定……………………………………………1

1.3 塑件注塑工艺参数的确定………………………………………………2

第二章 注塑模的结构设计

2.1 分型面的选择……………………………………………………………2

2.2 确定型腔的排列方式……………………………………………………3

2.3 浇注系统设计……………………………………………………………3

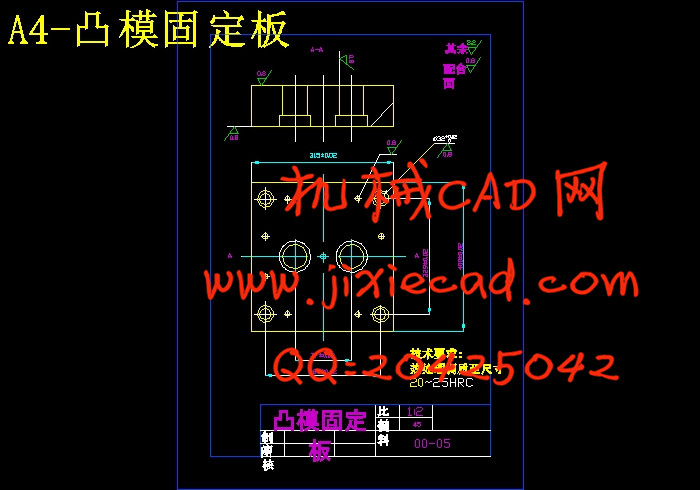

2.4 成型零件结构设计………………………………………………………4

第三章 模具设计的有关计算

3.1 成型尺寸的有关计算………………………………………………………5

3.2 圆形型腔的壁厚计算………………………………………………………6

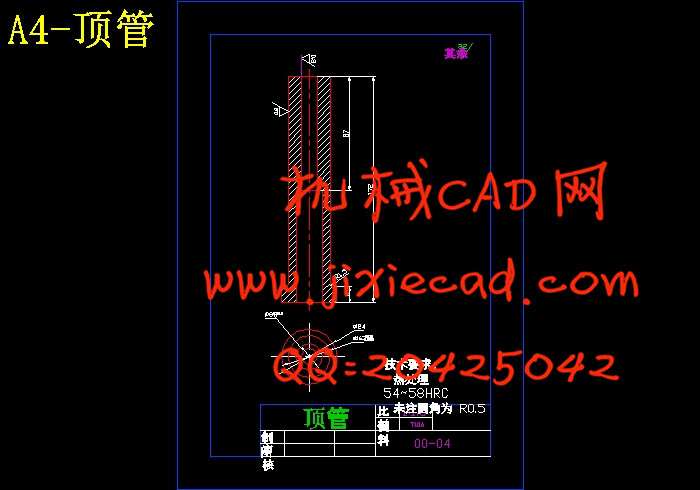

3.3 塑件脱模机构的设计………………………………………………………7

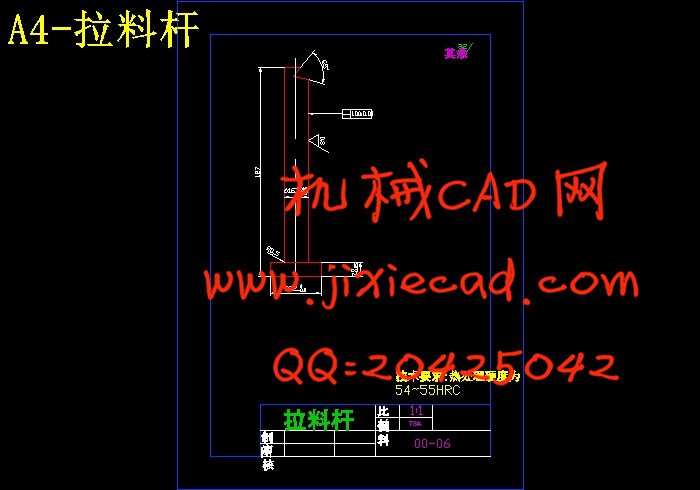

3.4 拉料杆型式的选择…………………………………………………………8

第四章 模具加热与冷却系统的设计

4.1 加热系统设计………………………………………………………………8

4.2 冷却系统设计………………………………………………………………9

4.3 冷却时间计算………………………………………………………………9

第五章 模具闭合高度的确定

5.1 模具闭合高度的确定……………………………………………………10

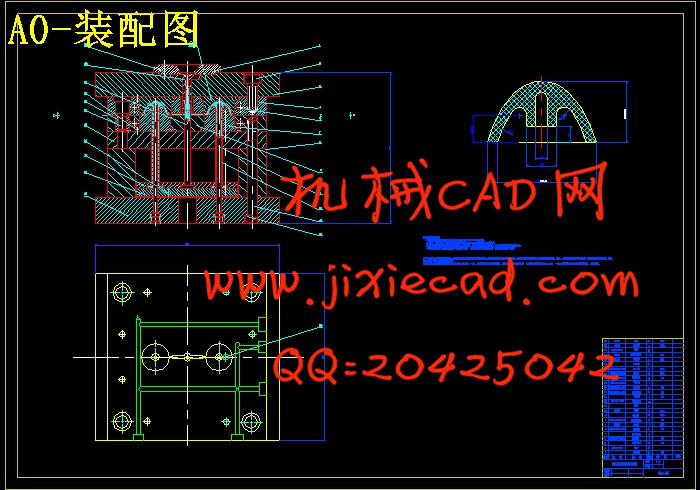

第六章 绘制模具总装图和非标准零件图

6.1 绘制模具总装图和非标准零件图……………………………………10

第七章 注塑模主要零件加工工艺规程的编制

7.1 注塑模主要零件加工工艺规程的编制………………………………11

结论…………………………………………………………………………… 13

致谢…………………………………………………………………… 19

参考文献………………………………………………………………………14

[摘要] 根据塑件的结构特点,提出适合整流罩零件注射成型的模具结构和设计了生产该零件的注射模,并详细描述了模具的工作过程。介绍了注射模的设计方案、设计要点和模具设计时应注意的问题,并对浇注系统的设计计算作了较详细的阐述。

根据注射模的结构和设计要求,该注射模采用了一模两件的模具结构和顶管顶出装置。根据注射模和注射机的关系选择注射机和确定塑件的注射工艺参数。注射模的结构设计包括分型面选择、确定型腔的排列方式、浇注系统设计和成型零件结构设计。成型零件结构设计包括凹模的结构设计、凸模的结构设计。

模具结构的简化,降低了模具成本。经生产验证,模具结构稳定,可靠,效果很好,对类似产品的注射模设计有很好的参考价值。

关键词:整流罩, 注塑模,模具结构,浇注系统。

(Design of injection mould for Cowling)

[Abstract] According to the structure characterstic of plastic part .the mould structure adapted to the injection moulding for the part was put forward,and the working process was describled in dectail .the injection mould for forming the part was designed to ensure the products up to the technical requirements .the scheme and main of design of the injection mould for Cowling was introduced ,and the paper presented some points in design that should be paid attention and design calculating was done for the system .

According to the structure of the injection mould and design requirements ,the die structure of two parts of one mould and liftout attachment of ring were adapted .according to the relation of the injection mould and injection molding machine , to select the injection mould machine and ensure the injection processing parameter of the plastic part . the structure of the injection mould consists of choice of mouldjoint ,confirmation of arrangement of impression ,design of the feed system ,design of the structure for moulding part . design of the structure for moulding part consists of the design of structure for die and punch .

The mold structure was predigested, the cost of the mold was evidently decreased. It was concluded from practical experitence that structure of the mold was stable , reliable and efficient . it provides a good reference for the design of injection mold for similar parts .

Key words: cowling , injection mould , mold structure , casting system.

目录

绪论……………………………………………………………1

第一章 模具工艺规程的编制

1.1 塑件的工艺性分析………………………………………………………1

1.2 模具型腔数和注塑机的选定……………………………………………1

1.3 塑件注塑工艺参数的确定………………………………………………2

第二章 注塑模的结构设计

2.1 分型面的选择……………………………………………………………2

2.2 确定型腔的排列方式……………………………………………………3

2.3 浇注系统设计……………………………………………………………3

2.4 成型零件结构设计………………………………………………………4

第三章 模具设计的有关计算

3.1 成型尺寸的有关计算………………………………………………………5

3.2 圆形型腔的壁厚计算………………………………………………………6

3.3 塑件脱模机构的设计………………………………………………………7

3.4 拉料杆型式的选择…………………………………………………………8

第四章 模具加热与冷却系统的设计

4.1 加热系统设计………………………………………………………………8

4.2 冷却系统设计………………………………………………………………9

4.3 冷却时间计算………………………………………………………………9

第五章 模具闭合高度的确定

5.1 模具闭合高度的确定……………………………………………………10

第六章 绘制模具总装图和非标准零件图

6.1 绘制模具总装图和非标准零件图……………………………………10

第七章 注塑模主要零件加工工艺规程的编制

7.1 注塑模主要零件加工工艺规程的编制………………………………11

结论…………………………………………………………………………… 13

致谢…………………………………………………………………… 19

参考文献………………………………………………………………………14