设计简介

摘 要

模具作为一种成型工具,其设计、制造水平的高低,直接关系到产品的质量与更新换代,是衡量一个国家产品制造水平的重要标志。

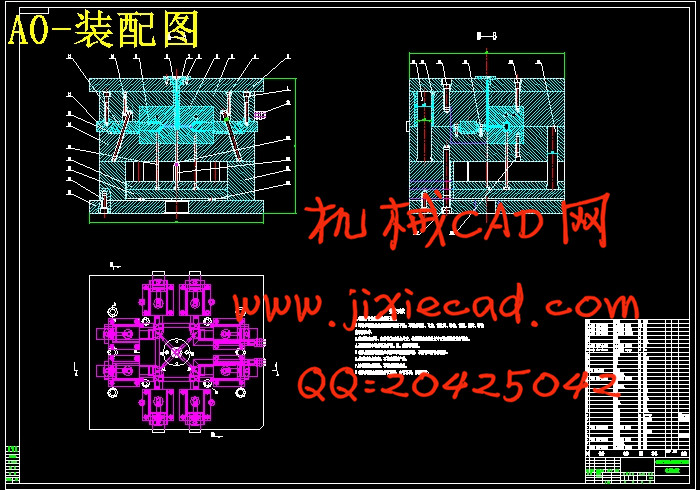

支撑管弯头体积较小、内部结构复杂,因而对注射成型模具和成型工艺的要求极高。支撑管弯头注射模设计制造的最大难点在于成型部件、浇注系统、脱模机构的设计。然后用Solidworks进行三维实体建模,再进行实体分析,确定出型腔数目,初选出成型设备,确定塑件的摆放位置,然后进行分型面的确定,浇口的确定,确定结构草图,再搭配Solidworks的moldflow可以非常有效的进行模架设计,然后进行抽芯机构,推出机构,复位机构的设计,冷却系统的设计,最后在Solidworks下进行机构模拟分析和校核。在这过程中经常发现不合理或者干涉的情况,然后分析这些状况产生的原因,然后进行修改,直到最后确定比较合理的方案。方案出来以后,再利用Solidworks的有限元分析功能对模具的受力部分进行强度校核,这也是Solidworks比较强大的功能之一。当完全确定没有问题的时候,就进行二维图形的绘制。在绘制二维图形的时候,运用目前机械行业最有有效的二维图纸绘制方法---由三维转成二维。这不但在设计的过程思维更加清晰, 把大量经历用于机构的优化和完善,最重要的是大大提高的绘图速度和准确性,这在目前的经济时代是非常重要的。

这套模具最重要的是通过传统和现代二种思维方法来设计的,可以亲身体会出二种方法各自的优缺点,取长补短。可以让传统工业焕发出新的活力,也提高了大家学习兴趣。

关键词: 注塑模具;支撑管弯头;浇注系统;装配工艺;

Abstract

Die as a tool for molding, its design, manufacture level are of direct bearing on the quality of products and replacement, an important indicator to measure a country's level of manufacturing.

Support elbow is of small size and complex internal structure, thus demanding a highly molding technique and injection die. The most difficult parts of Support elbow injection mould design and manufacture are the design of molding part, injection system, stripping structures. after demonstrated, I choose low-pressure polyethylene as the stuff. Second, I use Solidworks to do the three-dimensional sculpting for the entity for the sake of deciding the number of swage, equipment of injection, and the place of produce. Third, I choose the parting line, the gate, the sketch of the machinery, and arranged in pairs or groups imoldflow of Solidworks (in this way, we can design the mold’s carrier with effectively). Next, the machine of take out, fetch, return, and the cool system. The end, I use Solidworks to simulate the machine, besides analyses and check it. In the process, I always find the phenomenon of inconsequence and interference, when this phenomenon happened, I must analyses what’s wrong happened and why. Until I fine the whys, I must modify it. The end, I should decide the rational project. After the project is putted forward, I checked the intension of the pressed part of the mold with FEA of Solidworks. FEA is one of the power functions of Solidworks. After raveling out all problems, I should draw the planar chart. In the process of drawing——transform the three-dimensional chart to planar. In this way, my thinking became very in focus in the process of design, so I spend mostly energy to optimize and consummate the machine, the top-drawer is that we can heighten speed and veracity of drawing. At present, this is very important.

In the process of the design, I used traditionary technique and unconventional ways. Compared them, I found theirs strongpoint and disadvantage, so I can learn from other’s strong points to offset one's weakness. Improving the traditionary technique, besides improve our’s interest to study machine.

Key Words: Injection mold;Support elbow;Pouring system; Assembly process;

目 录

1. 绪 论 1

1.1国内外发展状况 1

1.1.1模具工业的概况 1

1.1.2我国塑料模具工业和技术状况及地区分布 2

1.1.3我国塑料模具工业和技术的今后的主要发展方向 5

1.1.4注塑模具CAD发展概况及趋势 5

1.2研究内容 7

1.2.1支撑管弯头外形设计 7

1.2.2分析最佳成型工艺 7

1.2.3模具结构分析和确定 7

1.2.4模具开合模运动仿真 7

2.支撑管弯头设计及其成型工艺分析 8

2.1制品结构和形状的设计 8

2.2制品材料的选择 9

2.2.1丙烯腈—丁二烯—苯乙烯三元共聚物(ABS) 9

2.2.2聚苯乙烯(PS) 9

2.2.3双酚A型碳酸脂(PC) 10

2.3注射工艺选择 12

2.3.1 ABS塑料的干燥 12

2.3.2注射压力 12

2.3.3注射温度 12

2.3.4模具温度 13

2.3.5料量控制 13

3.模具设计 14

3.1型腔数量的确定 14

3.2注塑机选型 14

3.2.1注射量计算 15

3.2.2注射机型号确定 16

3.2.3注射压力校核 16

3.2.4锁模力校核 16

3.2.5开模行程和模板安装尺寸校核 17

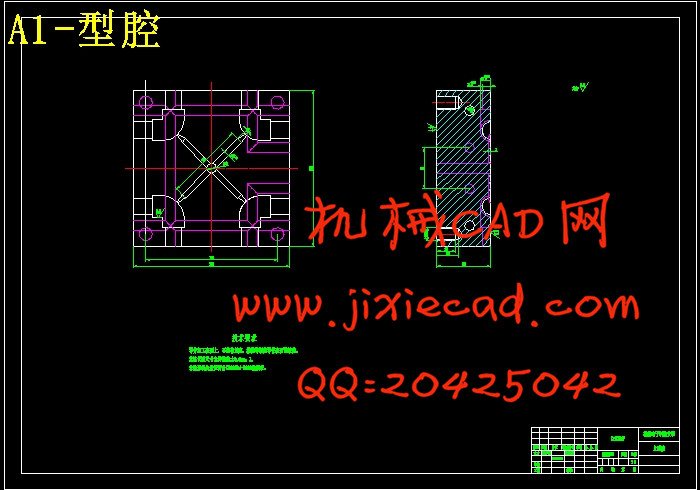

3.3模具浇注系统设计 18

3.3.1主流道设计 18

3.3.2分流道 18

3.3.3浇口设计 19

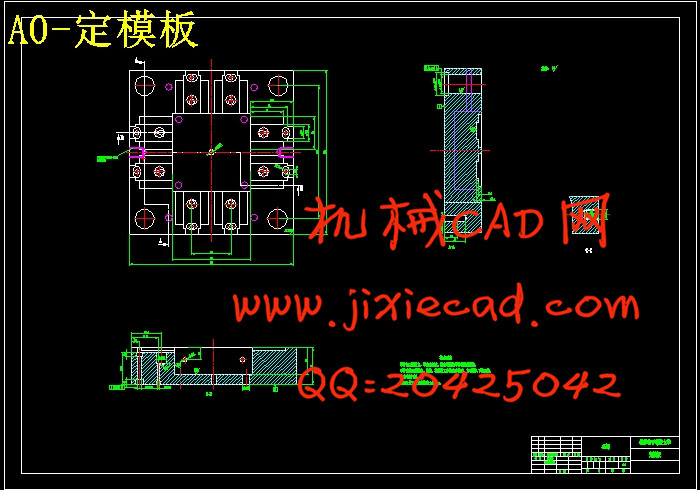

3.4注射模具成型零部件设计 20

3.4.1成型零部件尺寸分析 20

3.4.2塑件收缩率的影响 20

3.4.3成型零件的设计 21

3.4.3.1型腔 21

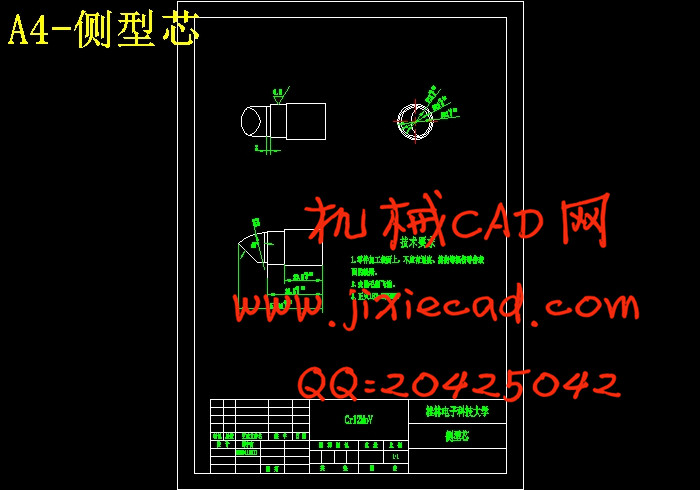

3.4.3.2侧型芯 22

3.4.4成型零部件强度校核计算 23

3.4.5型芯与型腔配合 23

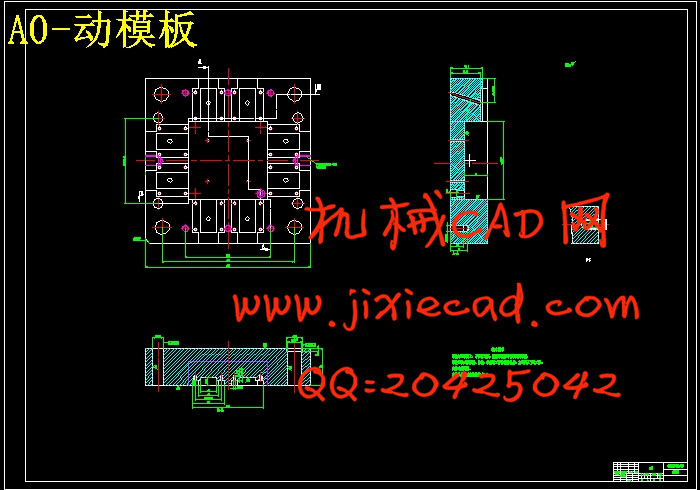

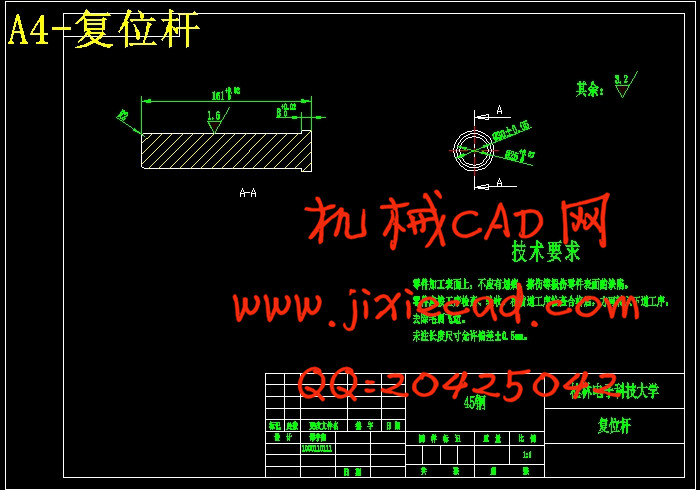

3.5脱模机构设计 24

3.6侧向抽芯设计 26

3.6.1机构设计 26

3.6.2确定抽芯距 27

3.6.3抽芯力的计算 27

3.6.4斜导柱设计 28

3.7导柱导向机构 29

3.7.1结构形式 29

3.7.2导柱结构和技术要求 30

3.7.3导套 30

3.8模具温度调节系统 31

3.9模具材料 31

4.模具装配工艺 33

4.1塑料模具的装配基准 33

4.2塑料模具的总装配程序 33

4.3塑料模具装配时注意事项 34

4.4空心球柄模具装配工艺 34

结 语 36

致 谢 37

参考文献 38