设计简介

除臭器外壳注射模具设计

摘 要

由于塑料具有许多金属和其它非金属所无法比拟的优点, 所以近年来发展尤为迅速。在现代工业和日用产品中,越来越多的塑料制品代替了以往的多类产品,而模具作为塑件的成型技术也得到了迅速发展。

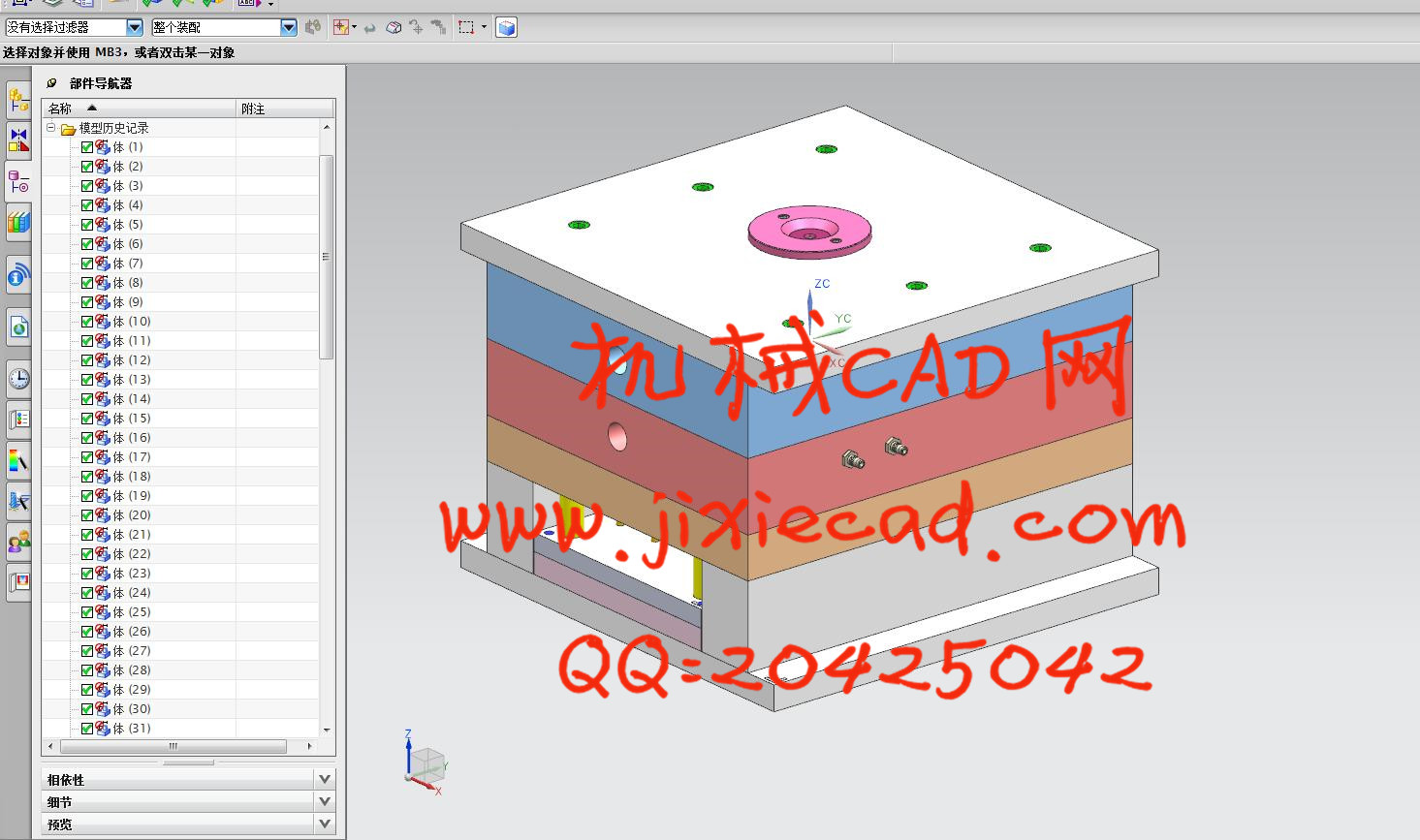

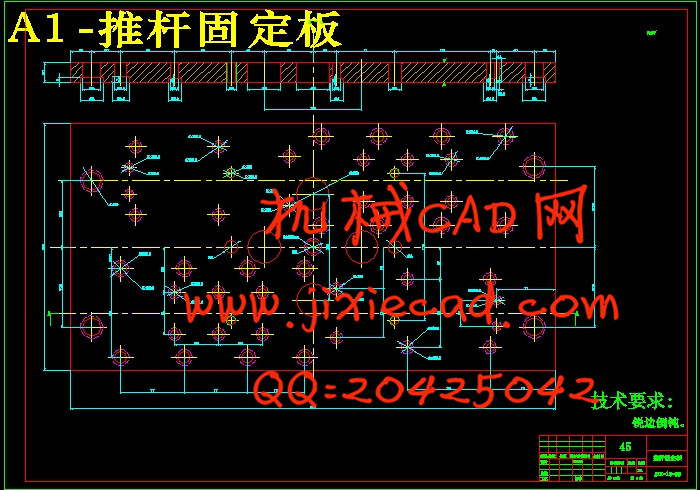

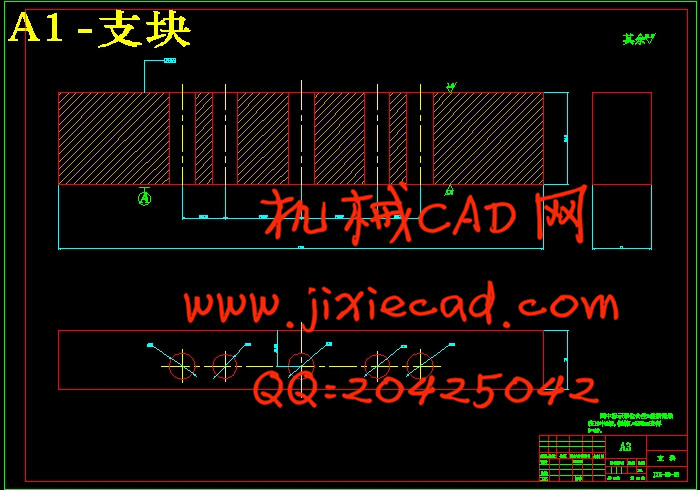

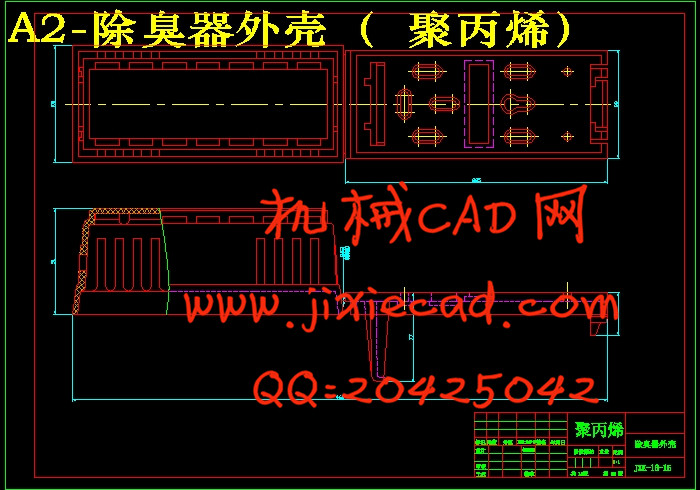

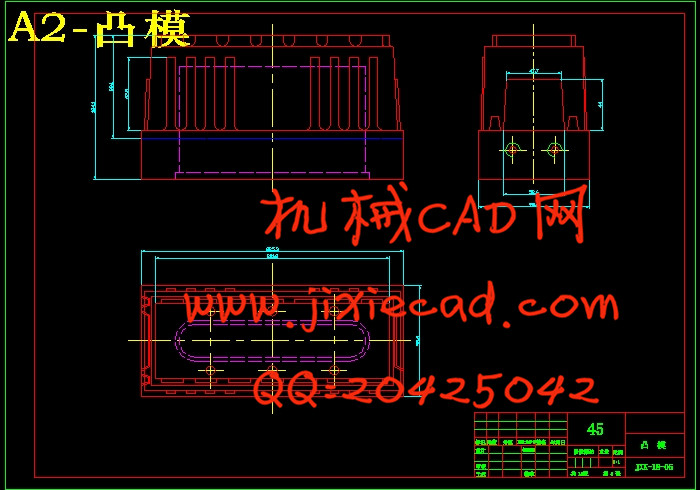

本次毕业设计就是在Pro ENGINEER平台上对除臭器外壳进行的注射模具设计。塑料注射模是模具中的一种,也是当今市场最常用、最具发展前景的模具之一。在设计过程中,通过了解和掌握塑料聚丙烯及除臭器外壳塑料模具设计的有关知识,主要完成注射塑料模具的成型部分、浇注系统、脱模机构、模体等部分的设计,并利用功能强大的CAD软件Pro ENGINEER进行三维造型及工过程的动画设计。

通过本次设计,不仅掌握了注射模具的基本设计过程和设计要领,并了解了塑料的基本成型工艺,以及软件Pro ENGINEER的实体建模、装配建模、制图基础、加工过程动画设计等各个环节的基本操作规则及运用方法,从而可以利用软件Pro ENGINEER或其它三维设计软件完成模具的整体设计。

关键词 塑料;注射模具;Pro ENGINEER

Injection Mold Design of the case of the deodorization chest

The design project for graduation is on the Pro ENGINEER platform to design the injection mould for the case of the deodorization chest. It is one of the molds, and also in nowadays market is the most in common used, most having the developing foreground of the mold insides the injection mould for plastics. In the design process, through the understanding and mastering the plastics polypropylene and the case of the deodorization chest, primarily complete to the plastics mould of type part, injection system, , and design the system for the plastics taking off and the frame of mold the etc. And make use of the Pro ENGINEER which is one of the CAD software with mighty functions to accomplish 3D shapes and Animation of worker's course.

After finishing this design, we not only control the basic process and the main points of the injection mould’s design, but also understood entity that the plastics's fundamental type craft, and the solid modeling, the assembly and the engineering drawing in Pro ENGINEER, Animation of worker's course, graphics the foundation to the basic operation rule and application method of the each link. Finally, we can make use of the Pro ENGINEER and other 3D soft ware to complete the mould overall design.

Keywords:Plastics; The injection mould for plastics; Pro ENGINEER

目 录

摘要…… I摘 要

由于塑料具有许多金属和其它非金属所无法比拟的优点, 所以近年来发展尤为迅速。在现代工业和日用产品中,越来越多的塑料制品代替了以往的多类产品,而模具作为塑件的成型技术也得到了迅速发展。

本次毕业设计就是在Pro ENGINEER平台上对除臭器外壳进行的注射模具设计。塑料注射模是模具中的一种,也是当今市场最常用、最具发展前景的模具之一。在设计过程中,通过了解和掌握塑料聚丙烯及除臭器外壳塑料模具设计的有关知识,主要完成注射塑料模具的成型部分、浇注系统、脱模机构、模体等部分的设计,并利用功能强大的CAD软件Pro ENGINEER进行三维造型及工过程的动画设计。

通过本次设计,不仅掌握了注射模具的基本设计过程和设计要领,并了解了塑料的基本成型工艺,以及软件Pro ENGINEER的实体建模、装配建模、制图基础、加工过程动画设计等各个环节的基本操作规则及运用方法,从而可以利用软件Pro ENGINEER或其它三维设计软件完成模具的整体设计。

关键词 塑料;注射模具;Pro ENGINEER

Injection Mold Design of the case of the deodorization chest

Abstract

Because the plastics have many advantages that the metals and other nonmetals with for can't compare to, it developed quickly these yeas. In the modern industry and the articles for daily use, more and more plastic products replaced many products of former, and the mould as the technique of mould for plastic also got the quick development.The design project for graduation is on the Pro ENGINEER platform to design the injection mould for the case of the deodorization chest. It is one of the molds, and also in nowadays market is the most in common used, most having the developing foreground of the mold insides the injection mould for plastics. In the design process, through the understanding and mastering the plastics polypropylene and the case of the deodorization chest, primarily complete to the plastics mould of type part, injection system, , and design the system for the plastics taking off and the frame of mold the etc. And make use of the Pro ENGINEER which is one of the CAD software with mighty functions to accomplish 3D shapes and Animation of worker's course.

After finishing this design, we not only control the basic process and the main points of the injection mould’s design, but also understood entity that the plastics's fundamental type craft, and the solid modeling, the assembly and the engineering drawing in Pro ENGINEER, Animation of worker's course, graphics the foundation to the basic operation rule and application method of the each link. Finally, we can make use of the Pro ENGINEER and other 3D soft ware to complete the mould overall design.

Keywords:Plastics; The injection mould for plastics; Pro ENGINEER

目 录

Abstract II

Abstract II

第1章 绪论 1

1.1 课题背景 1

1.2 模具发展前景 1

第2章 塑件与注射模具 3

2.1 塑料 3

2.1.1 塑料的使用性能及用途 3

2.1.2塑料的选用 3

2.2.1塑件几何形状 3

2.2 本章小结 4

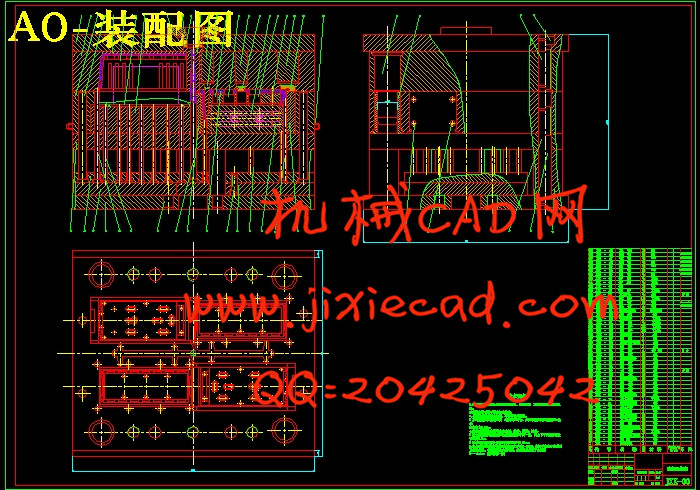

第3章 模具的设计 5

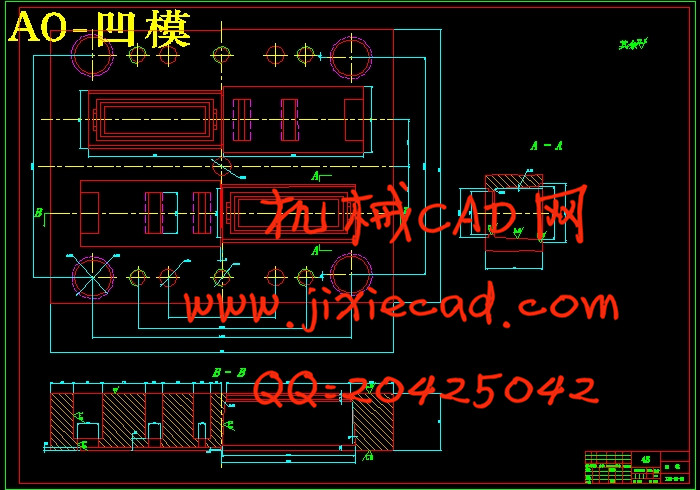

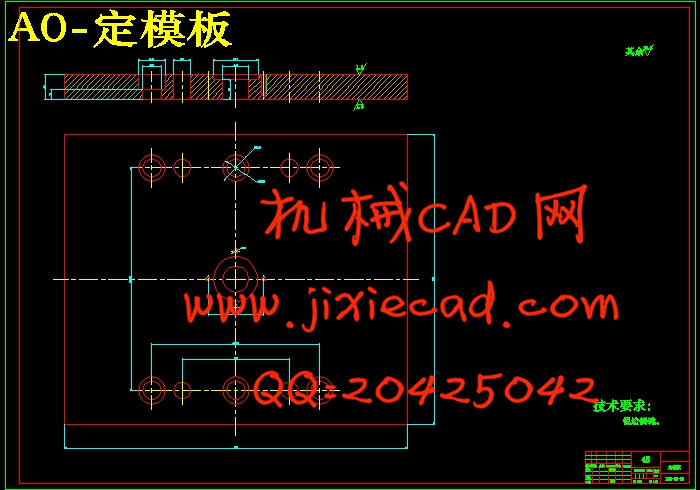

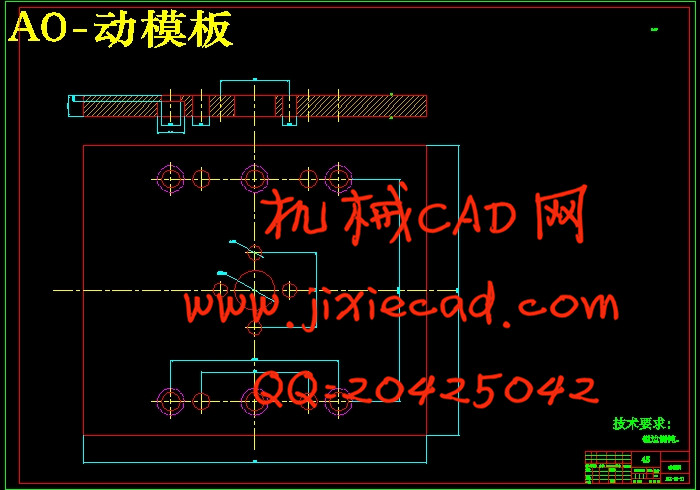

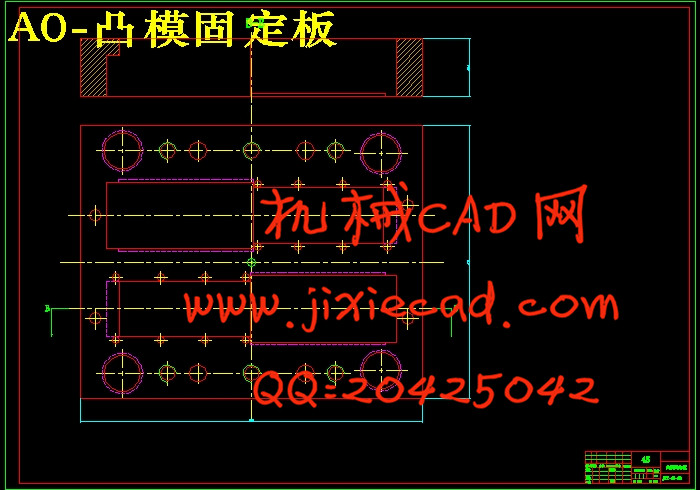

3.1 成型零件的结构及设计 5

3.1.1 分型面位置的确定 5

3.1.2型腔数目的确定 6

3.1.3型腔结构设计 6

3.2 动模板和定模板 8

3.3 注射机的确定 8

3.3.1注射机型号的确定 8

3.3.2最大注射量的校核 8

3.3.3锁模力的校核 9

3.4 浇注系统的设计 9

3.4.1主流道的结构设计 9

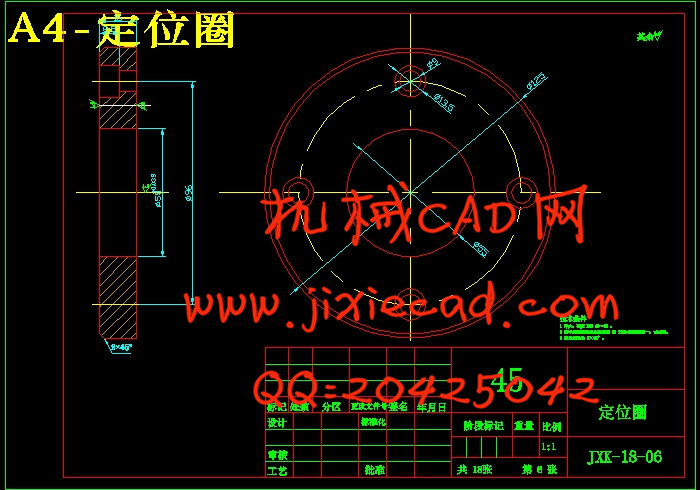

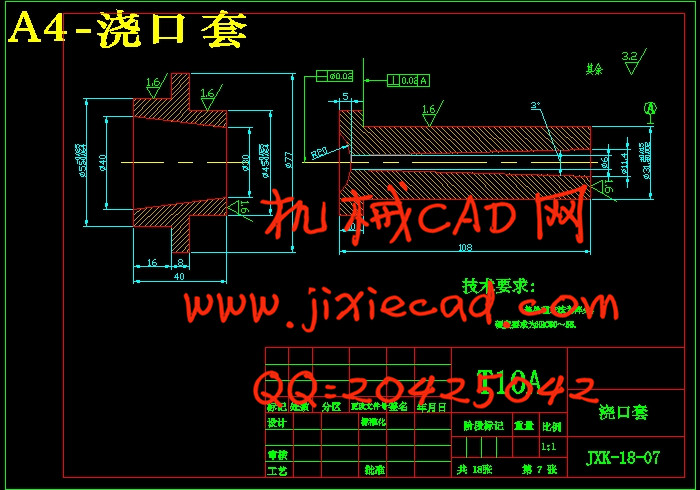

3.4.2浇口套 10

3.4.3分流道设计 11

3.4.4 分流道的形状及尺寸 11

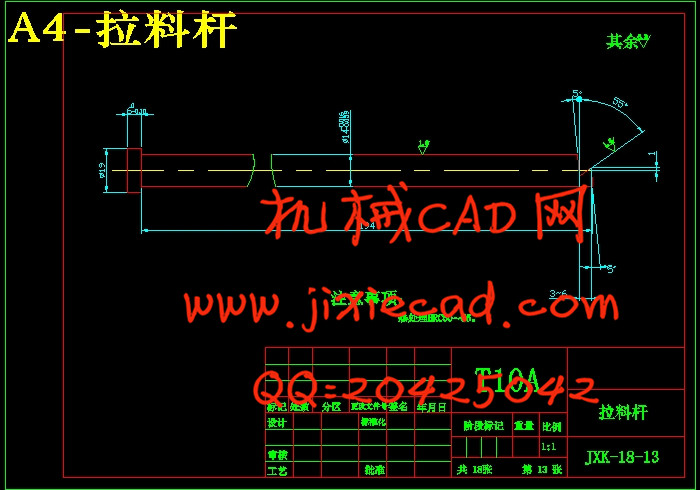

3.4.5浇口的设计 12

3.5 本章小结 13

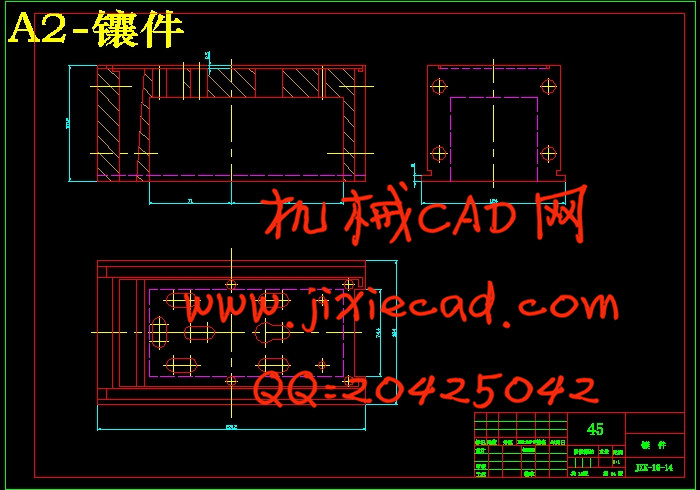

第4章 模具结构零部件设计 14

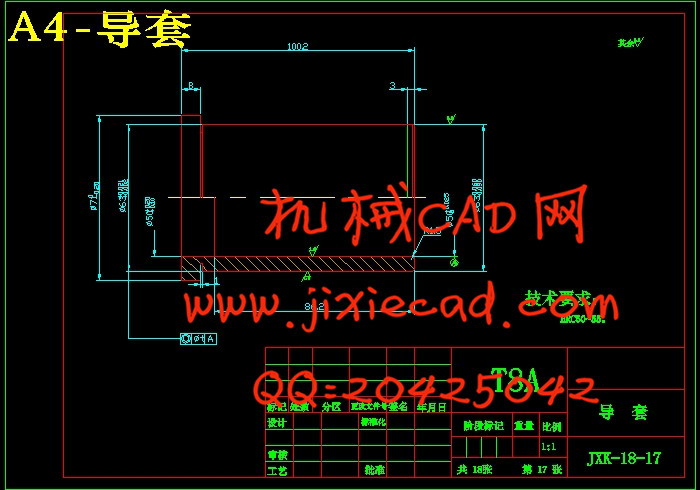

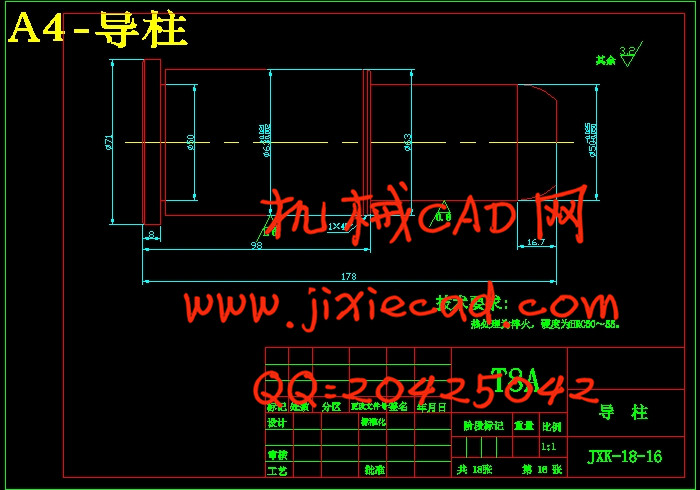

4.1 导向零件 14

4.1.1导柱的设计 14

4.1.2导套的设计 15

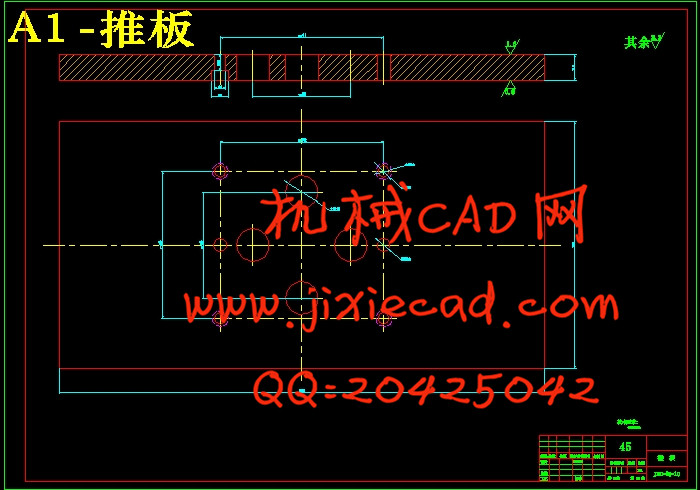

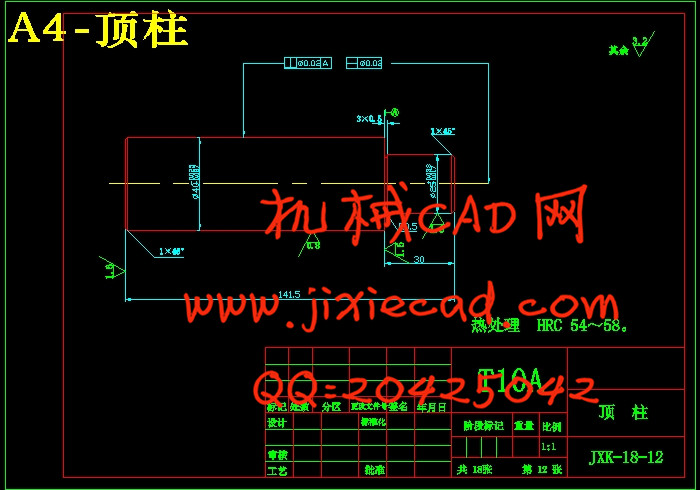

4.2 推杆 15

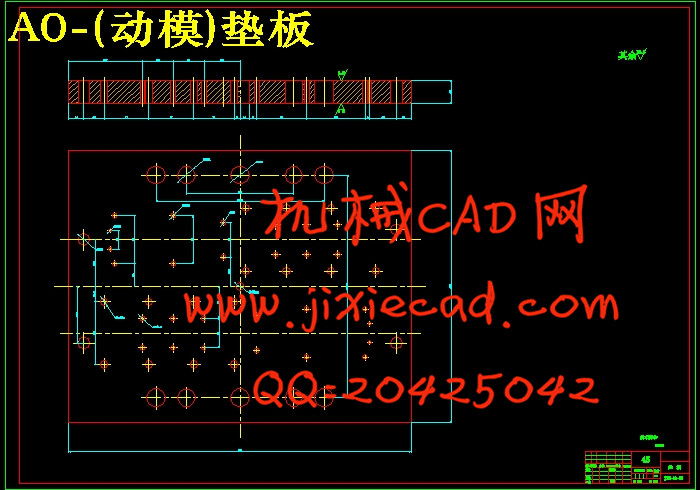

4.3 支承板设计 16

4.4 垫块设计 17

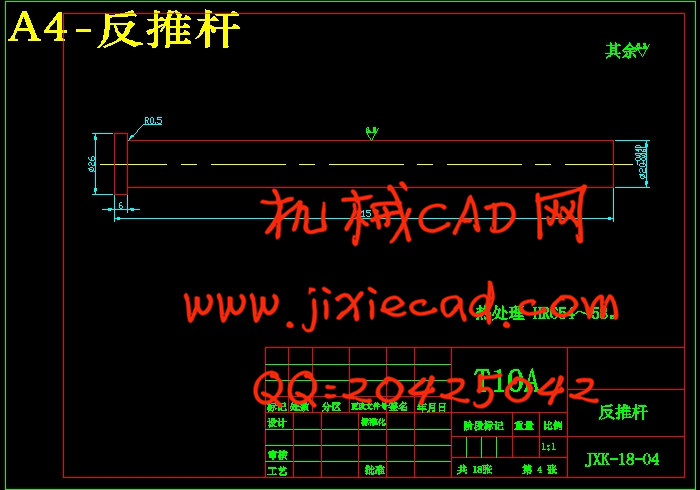

4.5 复位杆 18

4.6 本章小结 19

第5章 模具装配过程及动画设计 20

5.1 装配 20

5.1.1 子组的装配 20

5.1.2 模具的整体装配 21

5.2 动画设计 23

5.3 本章小结 27

结论 28

致谢 29

参考文献 30

附录2 数控加工程序 42