设计简介

摘 要

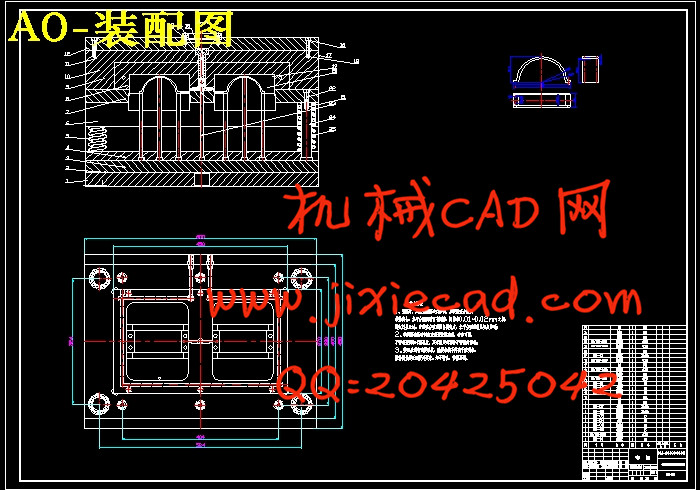

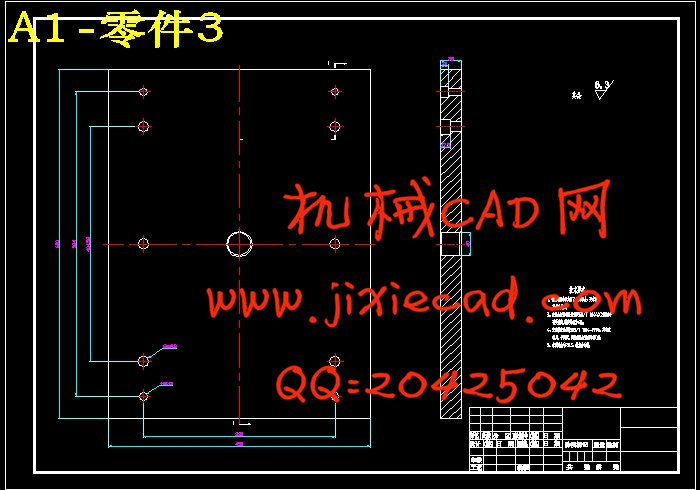

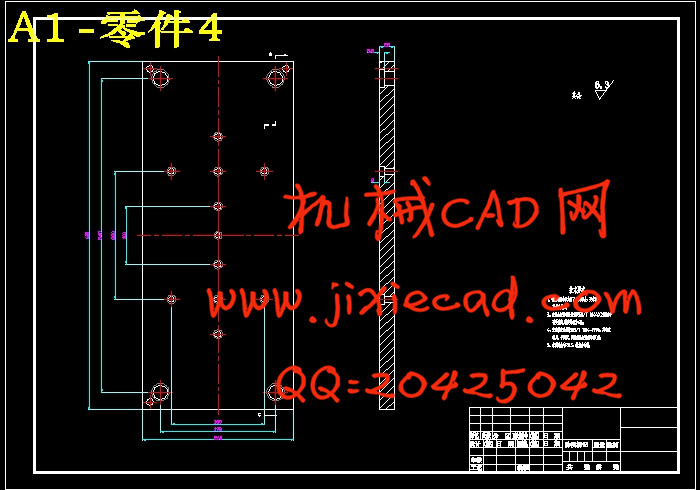

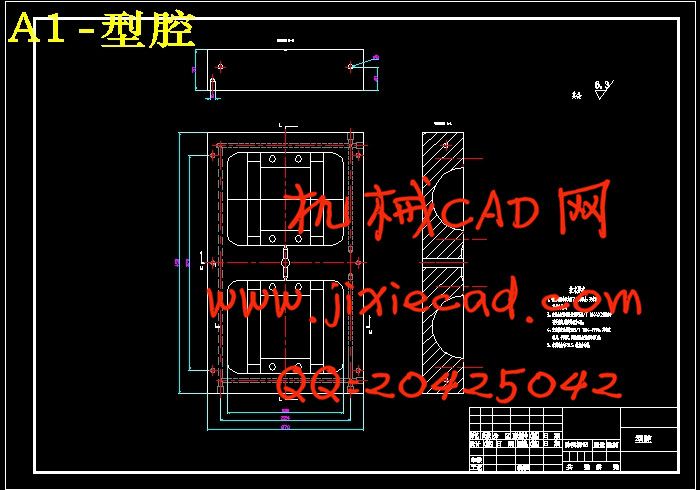

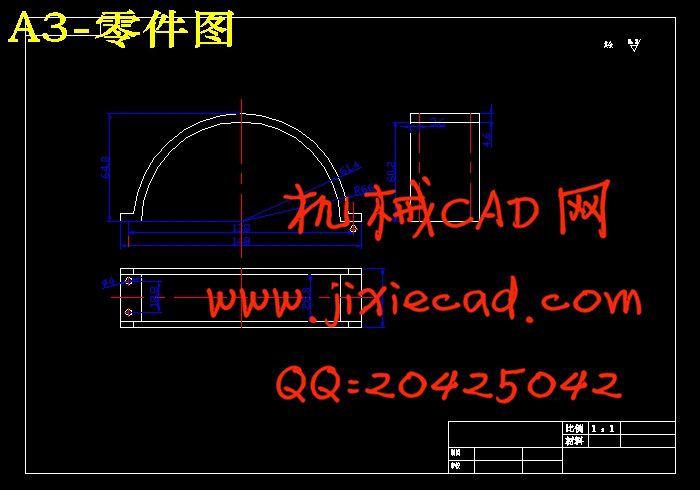

我们以社会实际产品为课题,设计一套能够生产所给塑件、结构合理、能保证制品的精度、表面质量的塑料模具,能熟练使用UG、CAD绘图。使我们在塑件结构设计、塑料成型工艺分析、塑料模具数字化设计、塑料模具零件的选材、热处理、塑料模具零件的制造,以及资料检索、英文翻译等方面获得综合训练,为缩短工作适应期奠定坚实的基础本设计的重点内容有以下几点:(1)要明确塑件设计要求:仔细阅读塑件制品零件图,从制品的塑料品种,塑件形状,尺寸精度,表面粗糙度等各方面考虑注塑成型工艺的可行性和经济性,必要时,要与产品设计者探讨塑件的材料种类与结构修改的可能性。(2)运用UG及CAD软件完成模具设计:分型面应选在塑件外形最大轮廓处,满足塑件的外观质量要求。(3)模具结构设计:塑件成型位置及分型面选择;模具型腔数的确定,型腔的排列和流道布局以及浇口位置设置;模具工作零件的结构设计;顶出机构设计;排气方式设计。(4)模具总体尺寸的确定和选购模架:模架已逐渐标准化,选定模架,在以上模具零部件设计基础上初步绘出模具的完整结构图。(5)模具结构总装图和零件工作图的绘制:模具总图绘制必须符合机械制图国家标准,模具总装图应该包括必要尺寸,如模具闭合尺寸,外形尺寸,特征尺寸,装配尺寸,极限尺寸及技术条件,编写零件明细表等。关键词:ABS;弯板;注射模具;推板机构;薄壁塑件;模具设计

Plastic bending plate injection molding process and mold design

Abstract

We take the actual product of society as the subject, design a set of production for plastic parts, reasonable structure, can guarantee the precision plastic mold, the surface quality of the products, able to skillfully use PROE, CAD/CAM mapping, CAE analysis software. We make the plastic parts in the structure design, plastic molding process analysis, plastic mold, plastic mold parts of the digital design and material selection, heat treatment, plastic mold manufacturing, comprehensive training and information retrieval, English translation and so on, in order to shorten the work period to lay a solid foundation for the design of the main content is as follows: (1) to clear plastic parts design requirements: read the product parts, products from plastic, plastic parts shape, size precision, considering the feasibility and economy of the injection molding process of all aspects of the surface roughness when necessary, to explore the possibility of modifying the material type and structure of plastic parts and products the designer. (2) using UG and CAD software to complete the mold design: parting surface should be in shape to meet the requirements of maximum contour, the appearance quality of plastic parts. (3) die structure design: molding position and parting surface selection; determine the mold cavity number, cavity arrangement and runner layout and gate location design; structure design of die parts; ejection mechanism design; exhaust system design. (4) to determine the overall size of the mold and the selection of mold: mold has been gradually standardized, the selected frame, complete structure design based on the above preliminary draw mold parts mold. (5) drawing die assembly drawing and parts drawing: drawing die drawing must comply with the national standard of mechanical drawing, mold assembly drawings should include the necessary dimensions, such as the closed mold size, shape size, feature size, assembly size, limit the size and technical conditions, preparation of parts list etc..

Key words: ABS warp, injection mold, push plate mechanism, thin wall plastic parts, mold design

目 录

1绪论 1

1.1模具工业产品结构的现状 1

1.2模具工业技术结构现状 1

1.3模具的发展趋势 2

1.3.1 模具CAD/CAE/CAM正向集成化、三维化、智能化和网络化方向发展 2

1.3.2模具检测、加工设备向精密、高效和多功能方向发展 2

1.4快速经济制模技术 3

1.5模具材料及表面处理技术发展迅速 3

2 塑料弯板注射模的结构设计与制造 4

2.1明确设计任务和准备必要的技术条件 4

2.2分析研究原材料的工艺特性和成型性能 4

2.2.1基本特性: 4

3塑件的工艺性分析 6

3.1塑料型号及其性能 6

3.2成型特点: 7

3.3模具工艺规程的编制 7

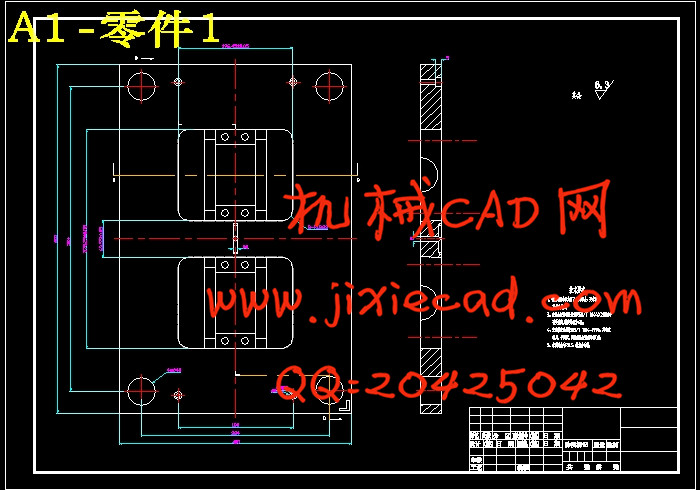

4 模具的结构形式 9

4.1分型面位置的确定 9

4.2型腔数量和排列方式确定 9

5 注射机型号的确定 12

5.1注射量的计算 12

5.2浇注系统凝料体积的初步估算 12

5.3选择注射机 12

5.4注射机的相关参数的校核 13

5.4.1注射压力校核 13

6浇注系统的设计 14

6.1主流道的设计 14

6.2分流道的设计 15

6.3浇口的设计 15

6.4侧浇口尺寸的确定 15

7 冷料穴的设计 17

7.1成型零件钢材的选用 17

8 排气孔道的设计 18

9 分型面的选择设计 19

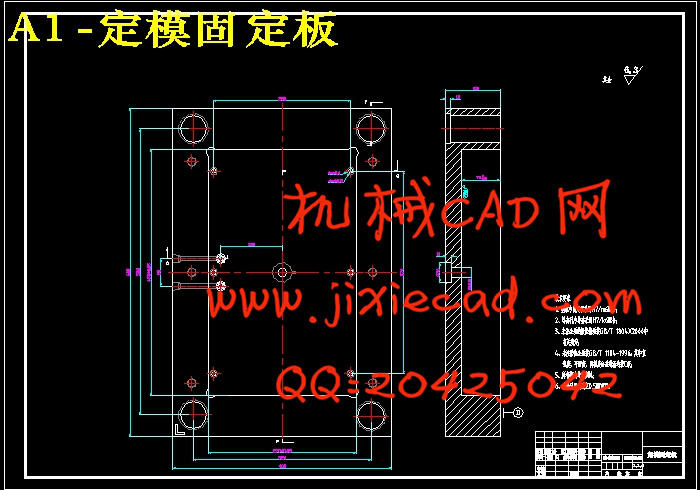

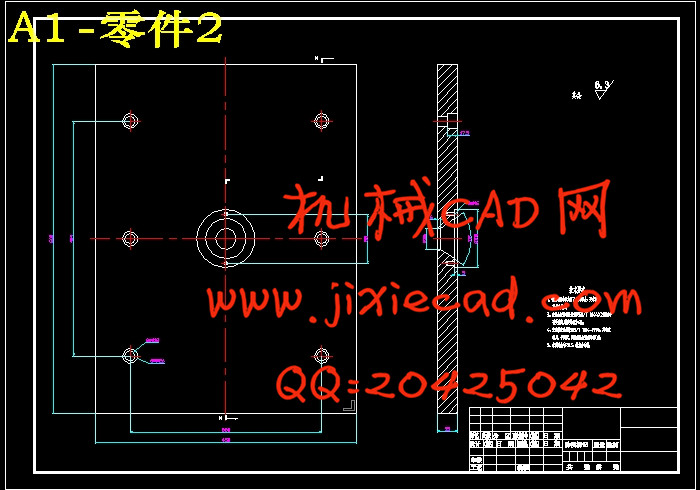

10 模架的选择与设计 20

10.1特点和用途: 20

10.2模架的确定 20

10.3各模板尺寸的确定 21

10.4模架各尺寸的校核 21

11顶出脱模机构设计 22

11.1 推出脱模机构的选取用原则 22

11.2脱模机构工作原理 22

11.3推板的设计 22

12 温调系统设计 23

12.1 模具加热与冷却系统对塑件质量的影响 23

12.2冷却介质 23

12.3凹模嵌件和型芯冷却水道的设置 23

14绘制模具的总装图 25

装配调试的工艺要求及注意问题 25

结束语 26

致谢 28