设计简介

洗发水瓶盖塑料成型工艺及模具设计

摘要:本设计题目为洗发水瓶盖注塑模设计,体现了盖类零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者注塑模的基础知识,为设计更复杂的注塑模具做好了铺垫并吸取了更深刻的经验。

本设计运用塑料成型工艺及模具设计的基础知识,首先分析了塑件的成分及性能要求,为选取浇口的类型做好了准备;然后估算了塑件的体积,便于选取注塑机及确定型腔数目;最后分析了塑件的特征,确定模具的设计参数,设计要点,及推出装置的选取。

通过分析洗发水瓶盖的工艺性,可知工件分型比较复杂,塑件采用顺序脱模法进行脱模分型。由于瓶盖的结构比较复杂,所以采用点浇口浇注系统,脱模后不在修正浇口的痕迹。但采用这种浇口时,常常要在模具上增加一个分型面,以便浇口凝料脱模。

关键词:工艺分析 塑件成型 浇注系统 模具结构

THE PLASTIC –FORMING AND MOLD DESIGN PROCESS OF SCREW CAP PARTS

Abstract: This design topic covers the note mold design for the thread, manifested has covered kind of components the design request, the content and the direction, had certain design significance.Through to this components mold design, further strengthened the designer to pour the mold the elementary knowledge, for designed the more complex injection molding mold to complete the upholstery to absorb a more profound experience.

Through the foundation knowledge, firstly, the composion and the perfourmance of thr part is analyzed to choose the type of the gat advantagely. Secondly, the volume of the part is estimated to choose the injection molding machine and to detemine the mould quantity conveniencely. Lastly the character of the part is analyzed to determine the mould design parameter and design point and choose the ejection assembly.

Through the analysis interrupted box thread bottle cap technology capability, may know the box thread is the semicircle thread, the models to use pulls out the core organization to carry on the drawing of patterns,Because bottle cap's on part request is strict, therefore uses the runner gating system, after the drawing of patterns, not in revision runner trace. But when uses this kind of runner, must increase a profile frequently on the mold, so that the runner can congeal the material drawing of patterns.

Keywords: process analysis; plastic parts moulding; casting system; molding structure.

目录

1 绪 论 3

1.1国内模具的现状和发展趋势 3

1.1.1国内模具的现状 3

1.2.1 国外模具现状 4

1.3.1 塑料模具的发展水平与市场趋势 5

1.4.1 洗发水瓶盖模具设计的设计思路 6

1.4.2洗发水瓶盖模具设计的进度 7

2 洗发水瓶盖工艺分析 8

2.1 洗发水瓶盖 8

2.1.1、材料分析 8

2.1.2、成型特性 9

2.2 洗发水瓶盖的结构分析 9

2.2.1 结构分析 9

3 凸凹模设计 10

3.1 分型面 10

3.2、凹模 10

3.2.1 制件质量、体积 10

3.2.2 布局 10

3.2.3 收缩率 11

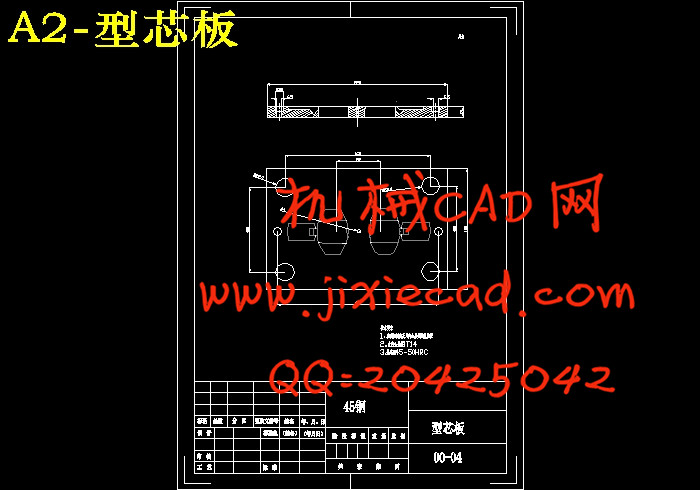

3.2.4 型腔板 11

3.3 选择模架 12

3.4 型芯 14

3.5 型芯、型腔选材 15

4 设计脱模方式及浇道 16

4.1 设计脱模方式 16

4.2 拉废料方式及尺寸 16

4.3 浇注系统 17

4.3.1 概述 17

4.3.2 主流道 18

4.3.3 分流道 18

4.3.4、浇口 18

5 注塑机 19

6 完善浇注系统 21

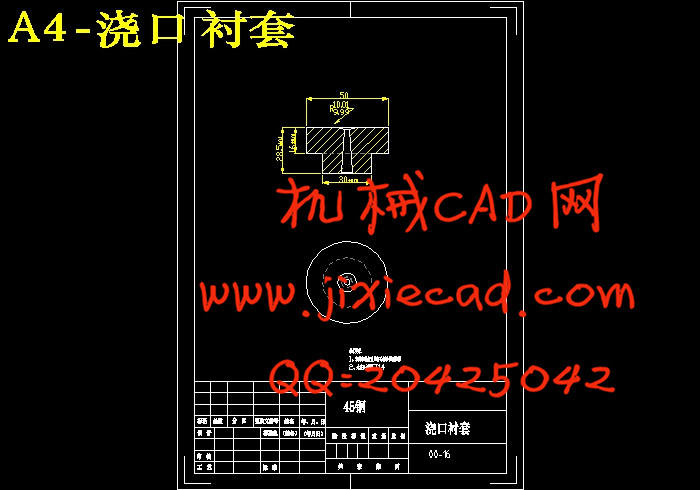

6.1 设计主流道衬套 21

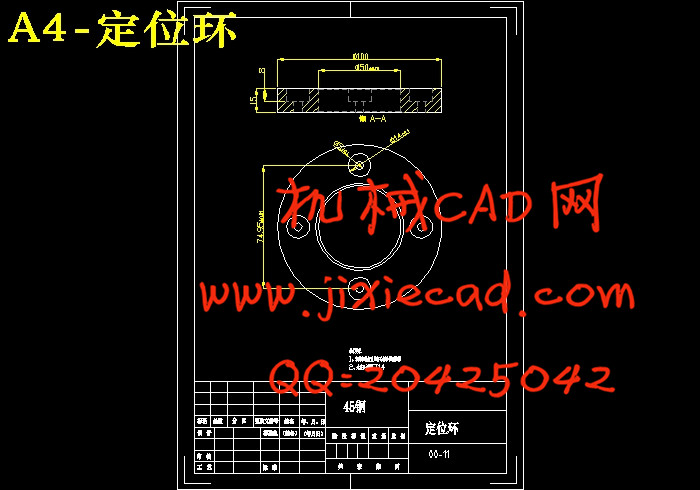

6.2设计定位环 22

7 冷却系统 23

7. 1 设计原则: 23

7.2 冷却水道 23

8 完善非标准零部件的设计 24

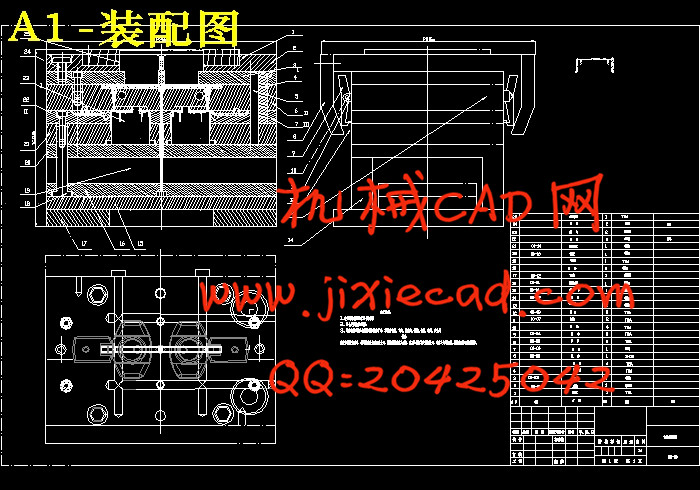

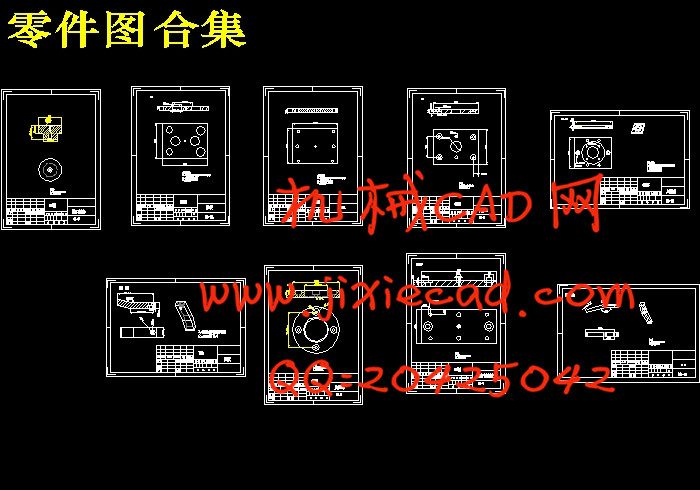

9 绘制模具的总装图和非标零件工作图 25

9.1 本模具的总装图 25

9.2本模具的工作原理 25

10 模具主要零件加工工艺规程的编制 错误!未定义书签。

10.1凹模的加工工序卡见附表1 错误!未定义书签。

10.2凹模的加工工艺过程卡见附表2 错误!未定义书签。

11 结论 26

致 谢 28

参考文献 29

摘要:本设计题目为洗发水瓶盖注塑模设计,体现了盖类零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者注塑模的基础知识,为设计更复杂的注塑模具做好了铺垫并吸取了更深刻的经验。

本设计运用塑料成型工艺及模具设计的基础知识,首先分析了塑件的成分及性能要求,为选取浇口的类型做好了准备;然后估算了塑件的体积,便于选取注塑机及确定型腔数目;最后分析了塑件的特征,确定模具的设计参数,设计要点,及推出装置的选取。

通过分析洗发水瓶盖的工艺性,可知工件分型比较复杂,塑件采用顺序脱模法进行脱模分型。由于瓶盖的结构比较复杂,所以采用点浇口浇注系统,脱模后不在修正浇口的痕迹。但采用这种浇口时,常常要在模具上增加一个分型面,以便浇口凝料脱模。

关键词:工艺分析 塑件成型 浇注系统 模具结构

THE PLASTIC –FORMING AND MOLD DESIGN PROCESS OF SCREW CAP PARTS

Abstract: This design topic covers the note mold design for the thread, manifested has covered kind of components the design request, the content and the direction, had certain design significance.Through to this components mold design, further strengthened the designer to pour the mold the elementary knowledge, for designed the more complex injection molding mold to complete the upholstery to absorb a more profound experience.

Through the foundation knowledge, firstly, the composion and the perfourmance of thr part is analyzed to choose the type of the gat advantagely. Secondly, the volume of the part is estimated to choose the injection molding machine and to detemine the mould quantity conveniencely. Lastly the character of the part is analyzed to determine the mould design parameter and design point and choose the ejection assembly.

Through the analysis interrupted box thread bottle cap technology capability, may know the box thread is the semicircle thread, the models to use pulls out the core organization to carry on the drawing of patterns,Because bottle cap's on part request is strict, therefore uses the runner gating system, after the drawing of patterns, not in revision runner trace. But when uses this kind of runner, must increase a profile frequently on the mold, so that the runner can congeal the material drawing of patterns.

Keywords: process analysis; plastic parts moulding; casting system; molding structure.

目录

1 绪 论 3

1.1国内模具的现状和发展趋势 3

1.1.1国内模具的现状 3

1.2.1 国外模具现状 4

1.3.1 塑料模具的发展水平与市场趋势 5

1.4.1 洗发水瓶盖模具设计的设计思路 6

1.4.2洗发水瓶盖模具设计的进度 7

2 洗发水瓶盖工艺分析 8

2.1 洗发水瓶盖 8

2.1.1、材料分析 8

2.1.2、成型特性 9

2.2 洗发水瓶盖的结构分析 9

2.2.1 结构分析 9

3 凸凹模设计 10

3.1 分型面 10

3.2、凹模 10

3.2.1 制件质量、体积 10

3.2.2 布局 10

3.2.3 收缩率 11

3.2.4 型腔板 11

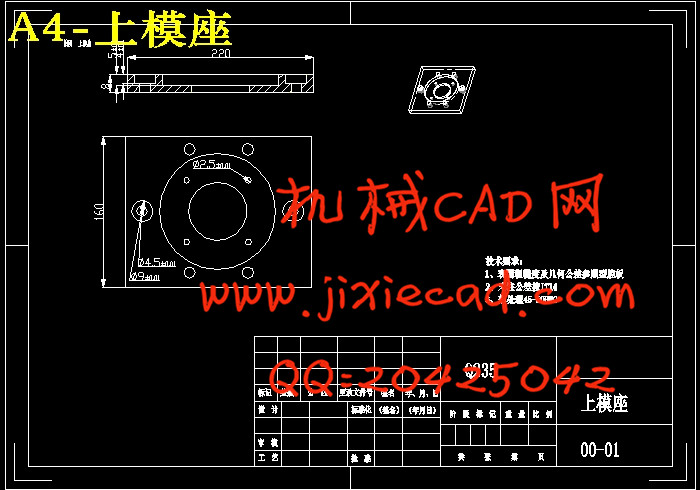

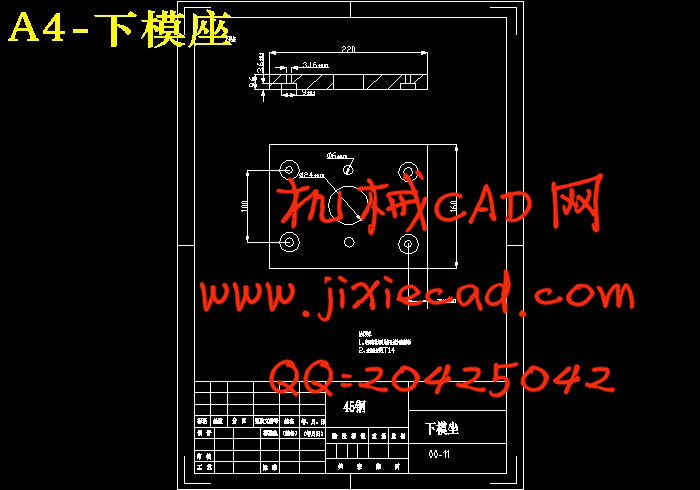

3.3 选择模架 12

3.4 型芯 14

3.5 型芯、型腔选材 15

4 设计脱模方式及浇道 16

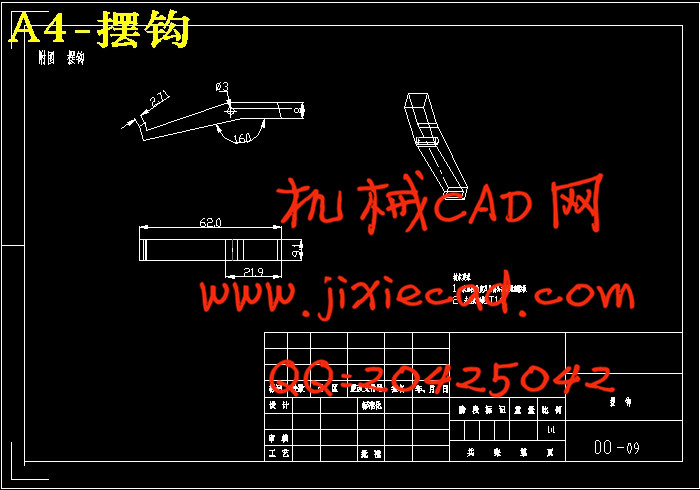

4.1 设计脱模方式 16

4.2 拉废料方式及尺寸 16

4.3 浇注系统 17

4.3.1 概述 17

4.3.2 主流道 18

4.3.3 分流道 18

4.3.4、浇口 18

5 注塑机 19

6 完善浇注系统 21

6.1 设计主流道衬套 21

6.2设计定位环 22

7 冷却系统 23

7. 1 设计原则: 23

7.2 冷却水道 23

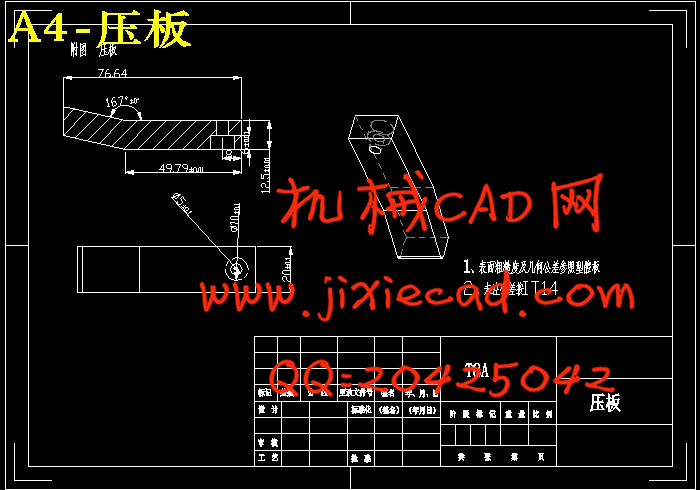

8 完善非标准零部件的设计 24

9 绘制模具的总装图和非标零件工作图 25

9.1 本模具的总装图 25

9.2本模具的工作原理 25

10 模具主要零件加工工艺规程的编制 错误!未定义书签。

10.1凹模的加工工序卡见附表1 错误!未定义书签。

10.2凹模的加工工艺过程卡见附表2 错误!未定义书签。

11 结论 26

致 谢 28

参考文献 29