设计简介

内容摘要

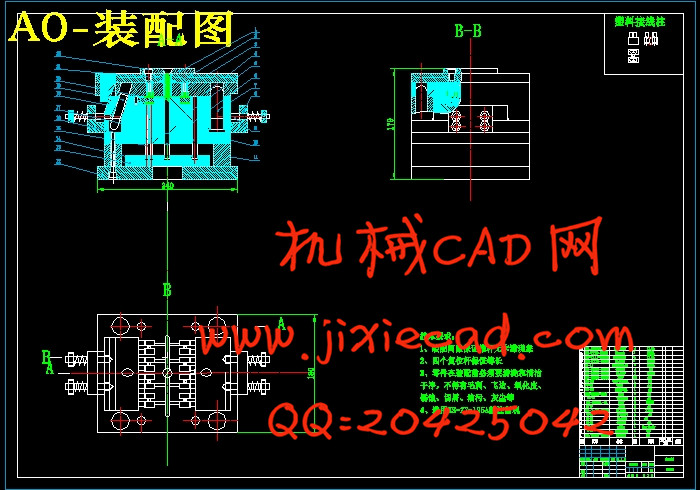

本次设计的是塑料接线柱塑料模具,体现了典型塑料模的设计要求、内容及方向,有一定的设计意义。通过对该模具的设计,加强了设计者对塑料模设计基础知识的理解和运用,为设计更复杂的塑料模具做好了铺垫。

本设计运用塑料模具工艺及模具设计的基础知识,首先分析了产品的性能要求,并选定合适的材料,然后进行了型腔分布设计以及三维立体建模,以选取合适的分型面;最后分析了产品的特征,便于确定模具的设计参数、设计要点及卸件装置。

本设计采用了一模八腔的结构。成型原理如下:首先将松散的粒状或粉末状成型物料从注塑机的料斗送入高温的机筒内加热、熔融、塑化。使之成为黏流溶体,然后再柱塞或螺杆的高压推动下,以很大的流速通过机筒前端的喷射嘴注射进入温度较低的闭合模具中,经过一段时间的保压冷却定型时间后,即可取出注射成型的塑胶接线柱。

成型过程如下:动定模板合模后,由注塑机注射将已加热到熔融状态的材料注射入型腔,经过主流道分流道,充满型腔后,经过一定的冷却保压后,动定模板分离,侧抽芯机构工作,抽芯完成后,压力机推动推板用顶杆推出制件,手动取出即可。

关键字:塑料模、材料、一模八腔、侧抽芯、成型原理、成型过程

English abstract

This design is about plastic binding post mold.it presents the typical plastic mold design requirements.there is a great significant in the concent and the directions.by designing the mold,it strengths the comprehension and using about the basic knowledge of designers.This is a good bedding to design the more complex plastic mold.

The design uses basic knowledge of plastic mold art.and mold designing.At first ,we analyze the products performance.and select the proper material and then design the mold cavity and it’s distribution.three dimension molding to choose the proper mold joint.At last,analyze the character of the product.In order to identify the design,data is the key point of the design and the equipment of the products.

The design use the construction of exactly eight cavity,these are the principle,first,we send the inattentive particulate matter and powder matter to the high heat machine hopper to heat,melt,and make them into dissolve matter,and then under the high pressure of plunger and screw,they go in a quick speed,through the melting jet in the head of the machine shotting the lower closed model.After the pressure of dynamic fixed clamping becomes cold.We can withdraw the fashioned binding post.

Following are the processes:the shot machine send the materials to the melting stoves. Passing by the primary and the secondary roads.Filling with the mold and after the cold pressure ,they separated.The side core-pulling began to work.When it comes to an end,the pressure machine push the knockout plate,and then,withdraw it with your hand.

The keyword:plastic mold、material、Exactly eight cavity、Side core-pulling、Forming principle、Molding process

目 录

第一章 塑件及材料的工艺分析············································1

1.1 设计任务的原始依据··················································1

1.2 塑件的工艺性分析················································2

1.3 型腔数目的确定···················································3

第二章 浇注系统的设计············································4

2.1确定分型面的位置············································4

2.2 确定浇口形式及位置············································4

2.3型腔位置的分布···············································5

2.4 主流道设计··························································5

2.5分流道设计··························································7

2.6浇口设计····························································7

第三章成型零部件设计·····················································8

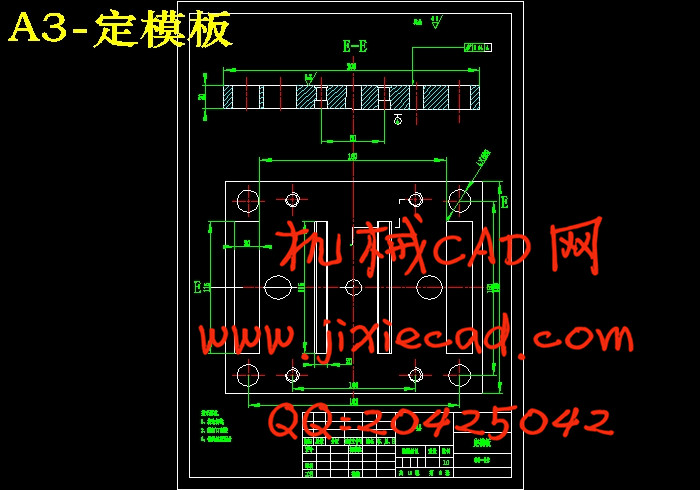

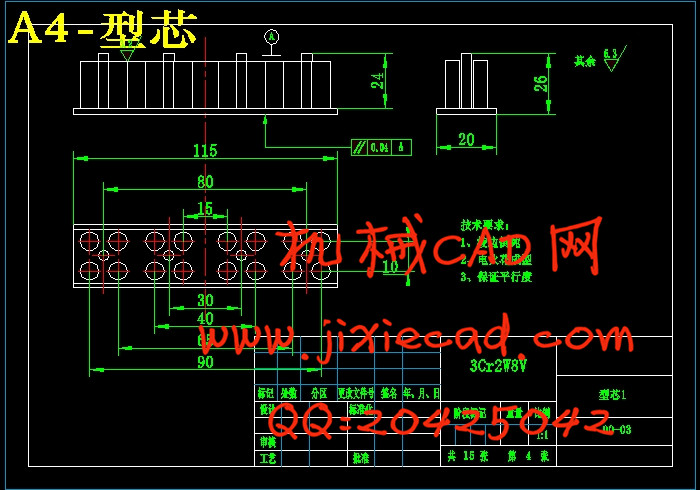

3.1成型零部件的结构设计················································8

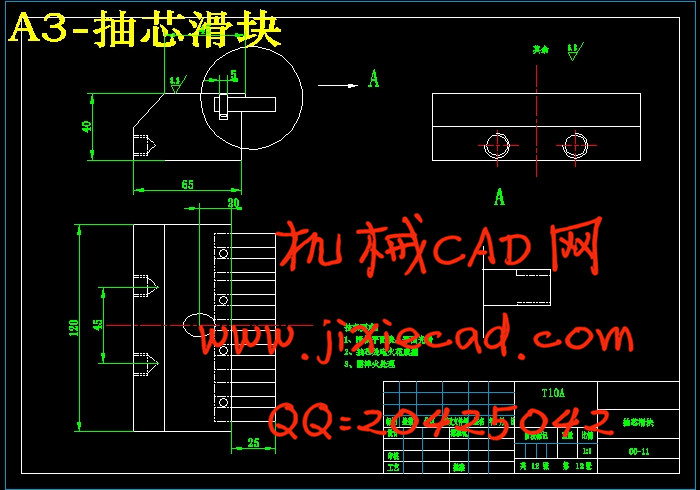

3.2模具侧向分型与抽芯机构的分析与确定··································9

3.3成型零部件尺寸的计算················································11

3.4导向机构设计························································15

第四章 推出机构和复位机构的设计··········································15

4.1推出机构的设计·············································15

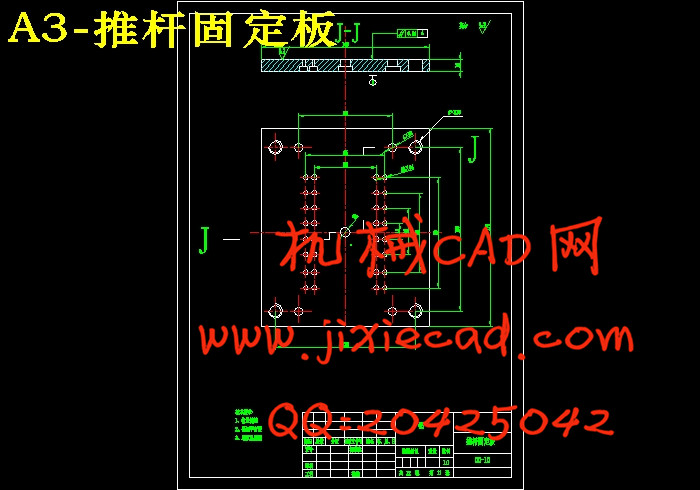

4.2推杆及复位设计······················································16

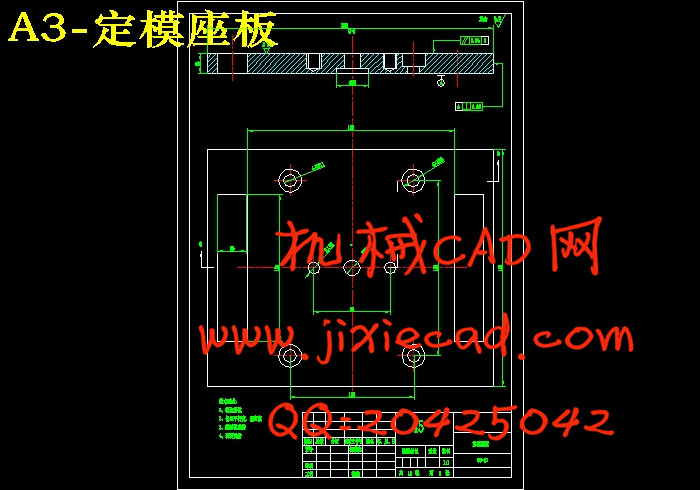

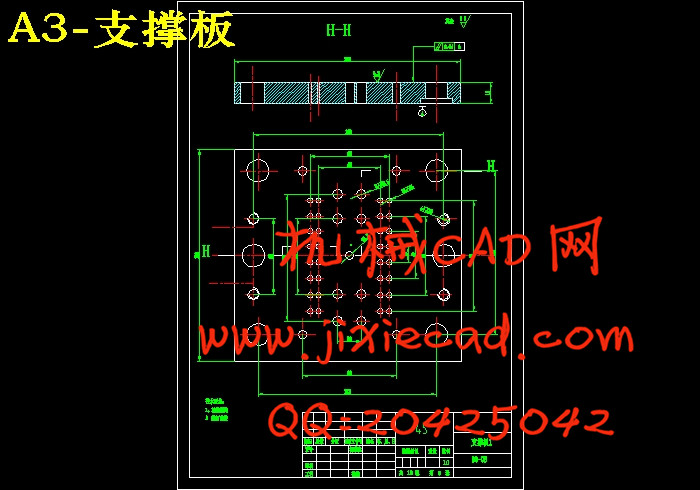

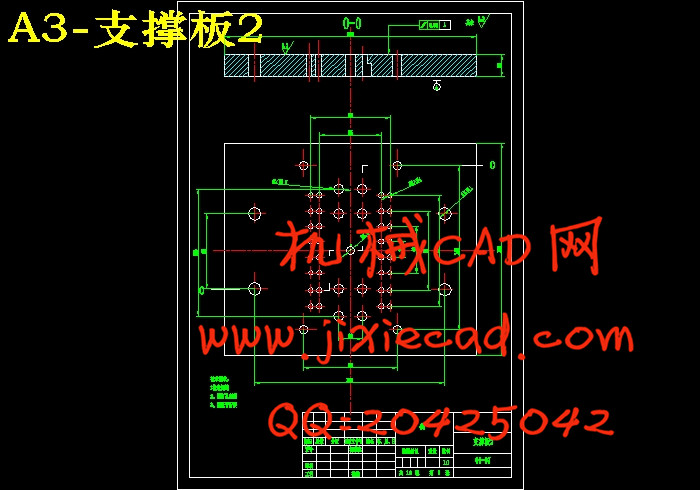

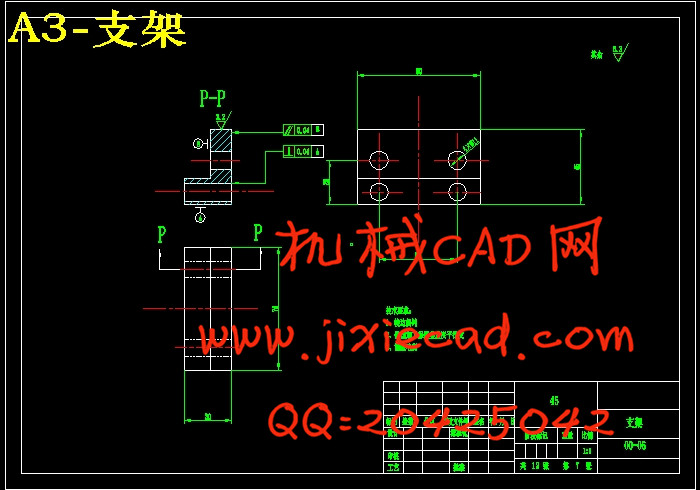

第五章支承与连接零件的设计与选择···························19

第六章 冷却系统和排气系统的设计··········································20

6.1冷却系统的设计···············································20

6.2排气系统的设计······················································20

第七章 选择注射机和标准模架··············································20

7.1初选注射机···············································21

7.2选择标准模架························································21

7.3注射机的校核·······················································22

第八章 结论······························································23

致谢····························································25

参考文献······················································26

本次设计的是塑料接线柱塑料模具,体现了典型塑料模的设计要求、内容及方向,有一定的设计意义。通过对该模具的设计,加强了设计者对塑料模设计基础知识的理解和运用,为设计更复杂的塑料模具做好了铺垫。

本设计运用塑料模具工艺及模具设计的基础知识,首先分析了产品的性能要求,并选定合适的材料,然后进行了型腔分布设计以及三维立体建模,以选取合适的分型面;最后分析了产品的特征,便于确定模具的设计参数、设计要点及卸件装置。

本设计采用了一模八腔的结构。成型原理如下:首先将松散的粒状或粉末状成型物料从注塑机的料斗送入高温的机筒内加热、熔融、塑化。使之成为黏流溶体,然后再柱塞或螺杆的高压推动下,以很大的流速通过机筒前端的喷射嘴注射进入温度较低的闭合模具中,经过一段时间的保压冷却定型时间后,即可取出注射成型的塑胶接线柱。

成型过程如下:动定模板合模后,由注塑机注射将已加热到熔融状态的材料注射入型腔,经过主流道分流道,充满型腔后,经过一定的冷却保压后,动定模板分离,侧抽芯机构工作,抽芯完成后,压力机推动推板用顶杆推出制件,手动取出即可。

关键字:塑料模、材料、一模八腔、侧抽芯、成型原理、成型过程

English abstract

This design is about plastic binding post mold.it presents the typical plastic mold design requirements.there is a great significant in the concent and the directions.by designing the mold,it strengths the comprehension and using about the basic knowledge of designers.This is a good bedding to design the more complex plastic mold.

The design uses basic knowledge of plastic mold art.and mold designing.At first ,we analyze the products performance.and select the proper material and then design the mold cavity and it’s distribution.three dimension molding to choose the proper mold joint.At last,analyze the character of the product.In order to identify the design,data is the key point of the design and the equipment of the products.

The design use the construction of exactly eight cavity,these are the principle,first,we send the inattentive particulate matter and powder matter to the high heat machine hopper to heat,melt,and make them into dissolve matter,and then under the high pressure of plunger and screw,they go in a quick speed,through the melting jet in the head of the machine shotting the lower closed model.After the pressure of dynamic fixed clamping becomes cold.We can withdraw the fashioned binding post.

Following are the processes:the shot machine send the materials to the melting stoves. Passing by the primary and the secondary roads.Filling with the mold and after the cold pressure ,they separated.The side core-pulling began to work.When it comes to an end,the pressure machine push the knockout plate,and then,withdraw it with your hand.

The keyword:plastic mold、material、Exactly eight cavity、Side core-pulling、Forming principle、Molding process

目 录

第一章 塑件及材料的工艺分析············································1

1.1 设计任务的原始依据··················································1

1.2 塑件的工艺性分析················································2

1.3 型腔数目的确定···················································3

第二章 浇注系统的设计············································4

2.1确定分型面的位置············································4

2.2 确定浇口形式及位置············································4

2.3型腔位置的分布···············································5

2.4 主流道设计··························································5

2.5分流道设计··························································7

2.6浇口设计····························································7

第三章成型零部件设计·····················································8

3.1成型零部件的结构设计················································8

3.2模具侧向分型与抽芯机构的分析与确定··································9

3.3成型零部件尺寸的计算················································11

3.4导向机构设计························································15

第四章 推出机构和复位机构的设计··········································15

4.1推出机构的设计·············································15

4.2推杆及复位设计······················································16

第五章支承与连接零件的设计与选择···························19

第六章 冷却系统和排气系统的设计··········································20

6.1冷却系统的设计···············································20

6.2排气系统的设计······················································20

第七章 选择注射机和标准模架··············································20

7.1初选注射机···············································21

7.2选择标准模架························································21

7.3注射机的校核·······················································22

第八章 结论······························································23

致谢····························································25

参考文献······················································26