设计简介

摘 要

本次设计是塑料注塑模具设计,注塑成型塑件为支撑块,其中的设计内容有零件的工艺性编制:塑件的工艺性分析、塑件的体积和质量计算及注射机参数的确定;结构设计:分型面选择、型腔数确定、浇口设计、侧向分型抽芯机构设计、推出及复位机构方式确定;型芯、型腔尺寸计算;模具加热和冷却系统计算;模具闭合高度确定;注射机有关参数的校核。

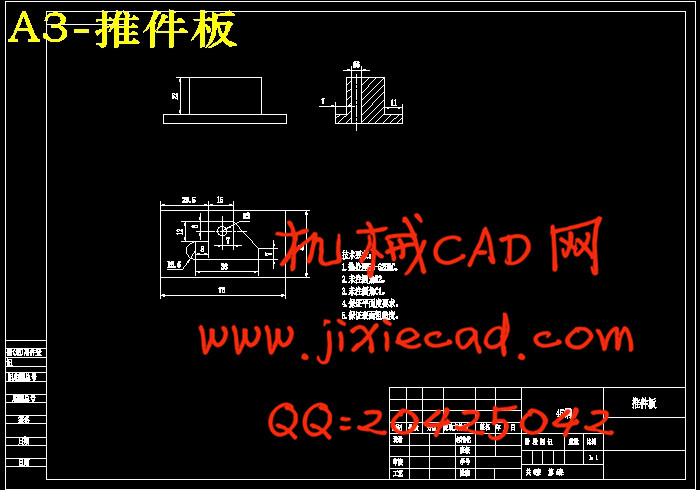

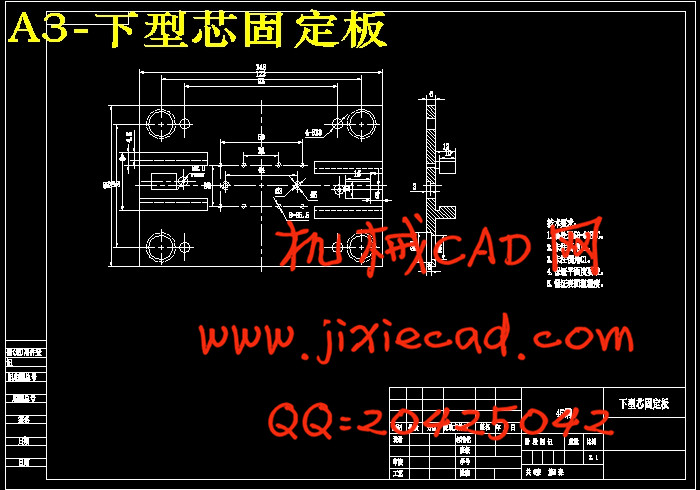

塑件尺寸较小,采用一模两腔,单分型面注射结构,把分型面选择在塑件水平投影最大的截面上,推件装置采用推板,推出平稳可靠,推出时不会在塑件上留下顶出痕迹,并采用斜导柱侧向分型机构。

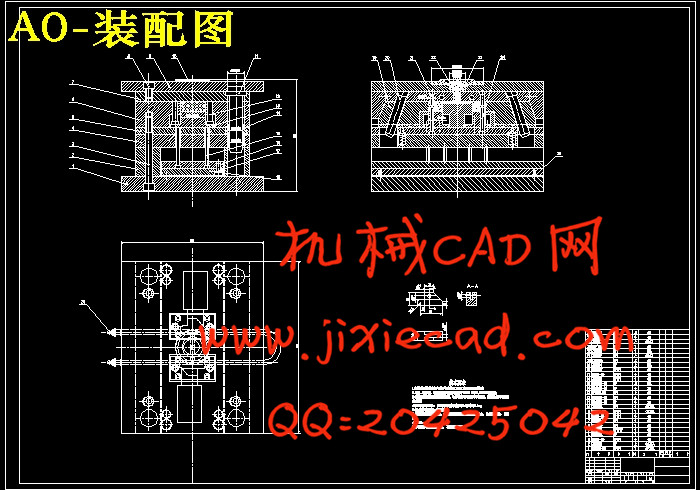

如此设计出的结构可确保模具工作运用可靠。最后对模具结构与注射机的匹配进行了校核,并用autoCAD绘制了一套模具装配图和零件图。

关键字:注塑成型;支撑块;结构设计;CAD

Design the injection mould of the support block

Abstract

This design is plastic injection mold design, plastic injection mold molding plastics is for supporting piece, The design contents are parts of technology establishment:technology Analysis of part,The computation of volume and quality of part,Injection machine parameter is determined;structural design:the choice of parting surface,the determine of cavity number,the design of the gate and the core-pulling mechanism,calculating the size Cores cavity;the calculation mould heating and cooling system,The mold closed highly determined;Injection machine related parameter examination.

Plastics has the smaller dimension, use a two-cavity, single parting surface injection structure,choose the parting surface in plastic parts on the biggest section level umbriferous, use push structure,running calmly and safely, Launched in plastic parts won't leave ejection trace, due to the plastics side has holes, so we must adopt slanted-guide-pillar core-pulling mechanism.

The design of such a structure can be used to ensure reliable Die work to ensure that the other parts of the tie. Finally has carried on the examination to the mold structure and the injection machine match.

Key word: injection moulding;supporting piece;the structural design;Computer - Aided Design

目录

1 绪 论 1

1.1 国际国内塑料成型模具发展概况 1

1.2 我国模具设计技术今后发展方向 2

1.3 毕业设计主要内容及任务 4

2 塑料制件的工艺性分析及工艺结构设计 5

2.1 成型塑料制件结构工艺性分析 5

2.2 塑件三维UG建模及分析 9

3 注塑模的结构设计 12

3.1 分型面的选择 12

3.2 型腔数目的确定及型腔的排列 12

3.3 浇注系统方案设计 14

3.4 型芯型腔结构设计 16

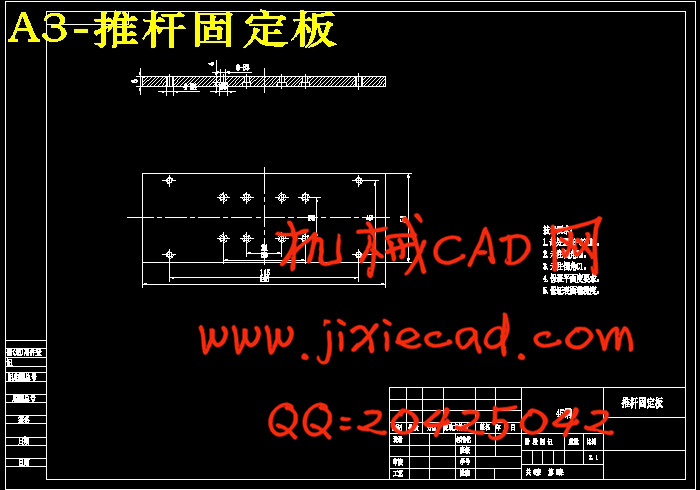

3.5 脱模机构设计 16

3.6 模架选取 18

4 注塑模具设计的有关尺寸计算 20

4.1 成型零件尺寸计算 19

4.2 脱模机构尺寸计算 20

4.3 楔紧块的形式 23

5 注塑机有关参数的校核 24

5.1 模具安装部分的校核 22

5.2 模具开模行程校核 22

6 模温调节与冷却系统的设计与计算 26

6.1 注射模冷却系统设计的原则 27

6.2 塑料模具的热平衡计算 28

7 绘制模具总装图及零件图 29

7.1 模具装配图的绘制 29

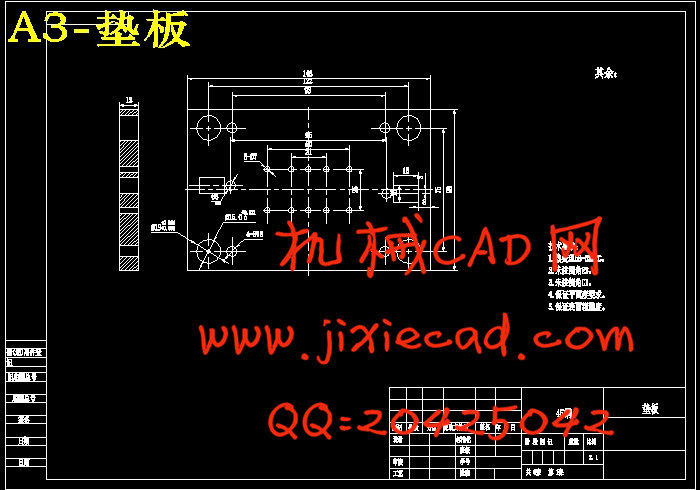

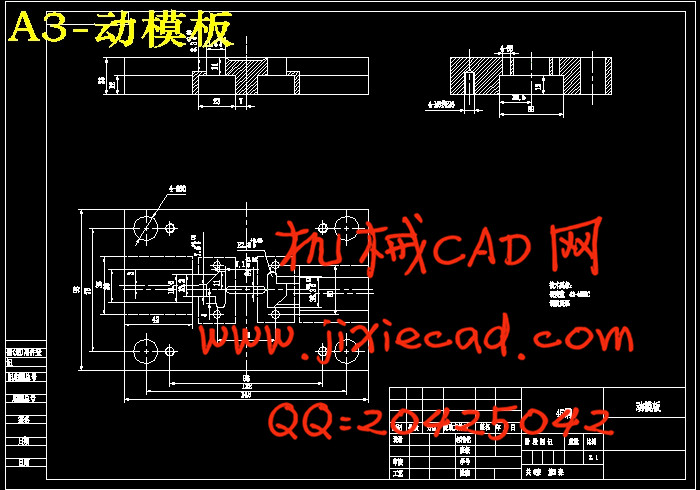

7.2 模具零件图的绘制 30

7.3 模具零件材料的选取 31

8 结论 33

参考文献 34

致谢 35

本次设计是塑料注塑模具设计,注塑成型塑件为支撑块,其中的设计内容有零件的工艺性编制:塑件的工艺性分析、塑件的体积和质量计算及注射机参数的确定;结构设计:分型面选择、型腔数确定、浇口设计、侧向分型抽芯机构设计、推出及复位机构方式确定;型芯、型腔尺寸计算;模具加热和冷却系统计算;模具闭合高度确定;注射机有关参数的校核。

塑件尺寸较小,采用一模两腔,单分型面注射结构,把分型面选择在塑件水平投影最大的截面上,推件装置采用推板,推出平稳可靠,推出时不会在塑件上留下顶出痕迹,并采用斜导柱侧向分型机构。

如此设计出的结构可确保模具工作运用可靠。最后对模具结构与注射机的匹配进行了校核,并用autoCAD绘制了一套模具装配图和零件图。

关键字:注塑成型;支撑块;结构设计;CAD

Design the injection mould of the support block

Abstract

This design is plastic injection mold design, plastic injection mold molding plastics is for supporting piece, The design contents are parts of technology establishment:technology Analysis of part,The computation of volume and quality of part,Injection machine parameter is determined;structural design:the choice of parting surface,the determine of cavity number,the design of the gate and the core-pulling mechanism,calculating the size Cores cavity;the calculation mould heating and cooling system,The mold closed highly determined;Injection machine related parameter examination.

Plastics has the smaller dimension, use a two-cavity, single parting surface injection structure,choose the parting surface in plastic parts on the biggest section level umbriferous, use push structure,running calmly and safely, Launched in plastic parts won't leave ejection trace, due to the plastics side has holes, so we must adopt slanted-guide-pillar core-pulling mechanism.

The design of such a structure can be used to ensure reliable Die work to ensure that the other parts of the tie. Finally has carried on the examination to the mold structure and the injection machine match.

Key word: injection moulding;supporting piece;the structural design;Computer - Aided Design

目录

1 绪 论 1

1.1 国际国内塑料成型模具发展概况 1

1.2 我国模具设计技术今后发展方向 2

1.3 毕业设计主要内容及任务 4

2 塑料制件的工艺性分析及工艺结构设计 5

2.1 成型塑料制件结构工艺性分析 5

2.2 塑件三维UG建模及分析 9

3 注塑模的结构设计 12

3.1 分型面的选择 12

3.2 型腔数目的确定及型腔的排列 12

3.3 浇注系统方案设计 14

3.4 型芯型腔结构设计 16

3.5 脱模机构设计 16

3.6 模架选取 18

4 注塑模具设计的有关尺寸计算 20

4.1 成型零件尺寸计算 19

4.2 脱模机构尺寸计算 20

4.3 楔紧块的形式 23

5 注塑机有关参数的校核 24

5.1 模具安装部分的校核 22

5.2 模具开模行程校核 22

6 模温调节与冷却系统的设计与计算 26

6.1 注射模冷却系统设计的原则 27

6.2 塑料模具的热平衡计算 28

7 绘制模具总装图及零件图 29

7.1 模具装配图的绘制 29

7.2 模具零件图的绘制 30

7.3 模具零件材料的选取 31

8 结论 33

参考文献 34

致谢 35