设计简介

小油壶盖注塑模具设计

摘 要

注射成型是成型热塑性塑料的一个主要方法,可以一次成型形状复杂且要求精密的塑件。本设计主要是小油壶盖注塑模具的设计,以此为例,介绍了常用注塑模具的设计方法和流程。首先对小油壶盖结构进行了工艺分析,采用LDPE塑件作为材料。根据制件所用材料的工艺性能,选择注射机。再根据制件质量要求及外形特点选取标准模架,将已经测得的小油壶盖各部位尺寸代入公式进一步确定各零件的尺寸,进一步设计型腔、型芯、浇注系统、脱模系统等。接着对模具的材料进行了选择,以便设计出的结构可确保模具工作运行可靠。本设计主要用UG8.5进行小油壶盖三维图形的绘制,最后使用cad2014来完善装配图和各零件图。该设计方法对其他的一些不同结构产品的注塑模具设计有一定的参考价值。

关键词:小油壶盖,注塑模具,LDPE,模具设计

LDPETRACT

Injection molding is one of the main thermoplastics forming method, can be a complex shape and require precision for the plastic forming parts. This design is recited about mobile phone rear cover injection 没落的, as an example, this paper introduces the design methods of injection mould and process. First of all, the rear cover structure of mobile phone is executed through technical analysis, and the pristine material is used LDPE as the plastic parts. According to the stamping process performance of the materials used, the requirements of the quality and the shape the injection machine and standard mould frame are properly selected. The measured sizes of the mobile phone shell are generated into the formula to further determine the size of each part, and the cavity, core, pouring system, ejection system, etc. are further designed. In order to design the structure of reliable operation to ensure the mold work, the mould material is followed to choose. The 3-dimensional (3D) graphics drawing of rear cover of mobile phone is mainly designed using the software of UG8.5. Finally, the assembly drawing and part drawing is improved by using the software of cad2014. This design method of injection mould supplies a certain reference to other different structure product design.

KEY WORDS: Rear cover of mobile phone,Injection mold,LDPE,Mold design

目 录

前 言 4摘 要

注射成型是成型热塑性塑料的一个主要方法,可以一次成型形状复杂且要求精密的塑件。本设计主要是小油壶盖注塑模具的设计,以此为例,介绍了常用注塑模具的设计方法和流程。首先对小油壶盖结构进行了工艺分析,采用LDPE塑件作为材料。根据制件所用材料的工艺性能,选择注射机。再根据制件质量要求及外形特点选取标准模架,将已经测得的小油壶盖各部位尺寸代入公式进一步确定各零件的尺寸,进一步设计型腔、型芯、浇注系统、脱模系统等。接着对模具的材料进行了选择,以便设计出的结构可确保模具工作运行可靠。本设计主要用UG8.5进行小油壶盖三维图形的绘制,最后使用cad2014来完善装配图和各零件图。该设计方法对其他的一些不同结构产品的注塑模具设计有一定的参考价值。

关键词:小油壶盖,注塑模具,LDPE,模具设计

LDPETRACT

Injection molding is one of the main thermoplastics forming method, can be a complex shape and require precision for the plastic forming parts. This design is recited about mobile phone rear cover injection 没落的, as an example, this paper introduces the design methods of injection mould and process. First of all, the rear cover structure of mobile phone is executed through technical analysis, and the pristine material is used LDPE as the plastic parts. According to the stamping process performance of the materials used, the requirements of the quality and the shape the injection machine and standard mould frame are properly selected. The measured sizes of the mobile phone shell are generated into the formula to further determine the size of each part, and the cavity, core, pouring system, ejection system, etc. are further designed. In order to design the structure of reliable operation to ensure the mold work, the mould material is followed to choose. The 3-dimensional (3D) graphics drawing of rear cover of mobile phone is mainly designed using the software of UG8.5. Finally, the assembly drawing and part drawing is improved by using the software of cad2014. This design method of injection mould supplies a certain reference to other different structure product design.

KEY WORDS: Rear cover of mobile phone,Injection mold,LDPE,Mold design

目 录

第1章 绪论 6

1.1 模具在国民经济中的地位与作用 6

1.2 塑料模具的发展现状 6

1.3塑料模具工业的发展趋势及存在的问题 7

第2章 塑件的成型工艺性分析 10

2.1 小油壶盖材料的选择与性能分析 10

2.1.1 材料的选择 10

2.1.2 LDPE材料的性能分析 11

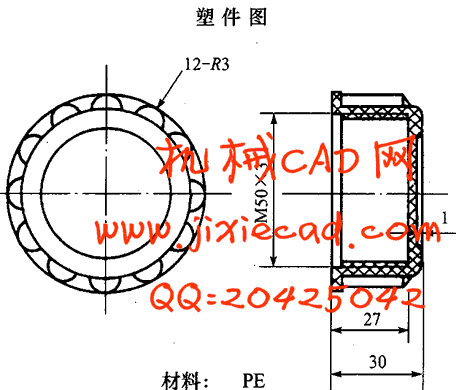

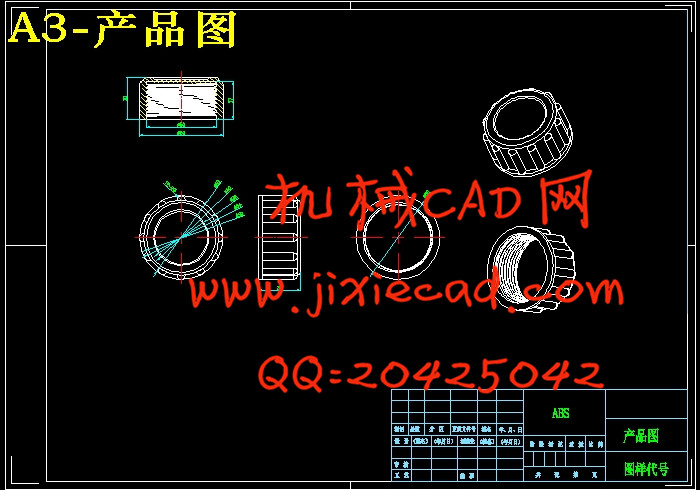

2.2 小油壶盖塑件的测绘 13

2.2.1 小油壶盖塑件的二维图 13

2.2.2 小油壶盖塑件的三维图 13

2.3 小油壶盖塑件的结构分析 14

第3章 模具结构形式的初步拟定 15

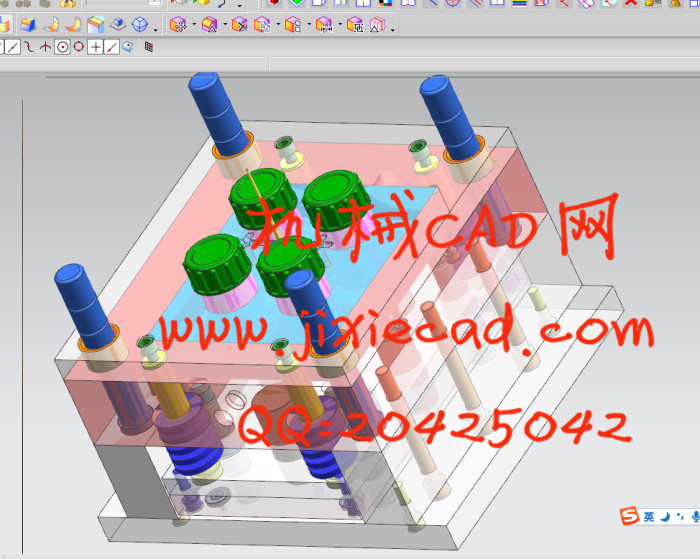

3.1 确定型腔数量及排列方式 15

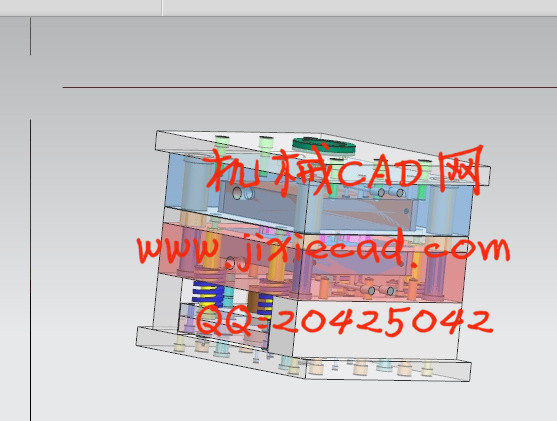

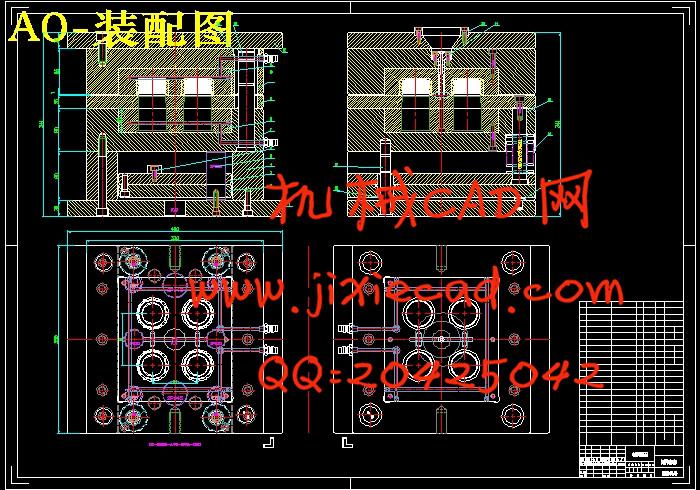

3.2模具结构形式的确定 16

第4章 成型设备的选用 18

4.1 注塑机的选择 18

4.1.1 小油壶盖塑件的计算 18

4.1.2 注塑机型号的初步确定 19

4.2 模架的选择 20

4.3 模具参数的校核 21

第5章 型腔排列方式与浇注系统的设计 24

5.1 型腔数量及排列方式的确定 24

5.2 浇注系统的设计 24

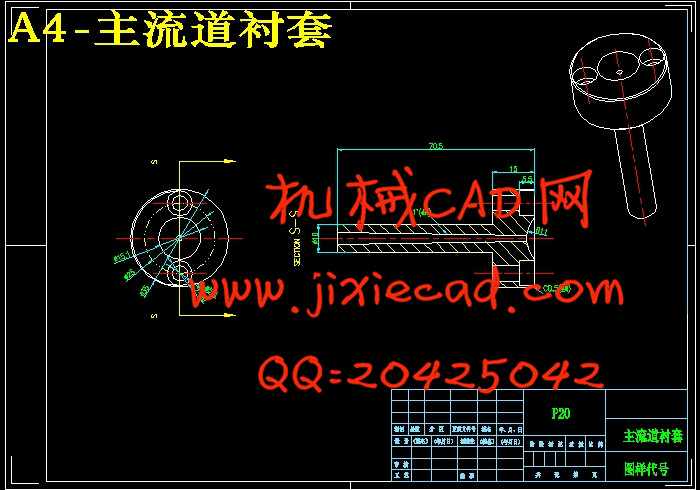

5.2.1 主流道的设计 24

5.2.2 分流道设计 25

5.2.3 浇口的设计 27

第6章 成型零部件设计 29

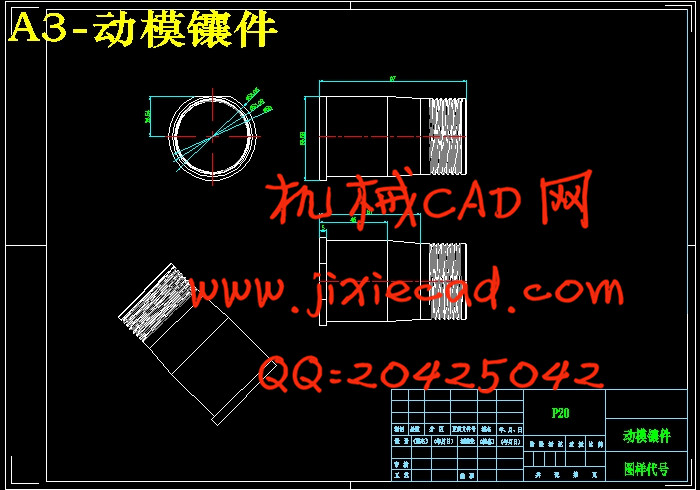

6.1 成型零部件的结构设计 29

6.2 成型零部件尺寸的计算 30

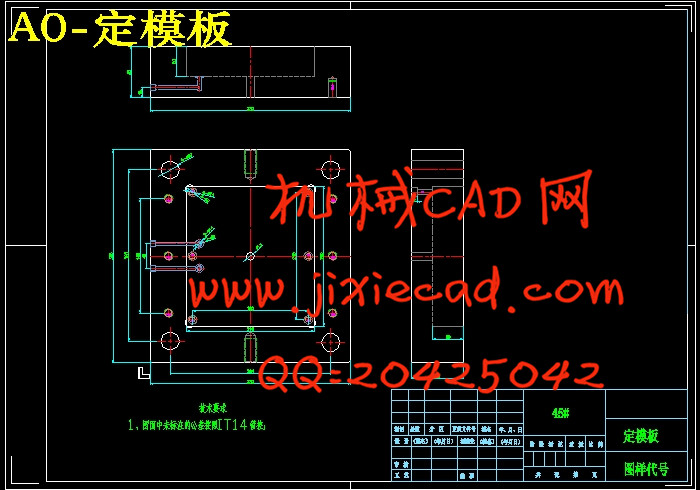

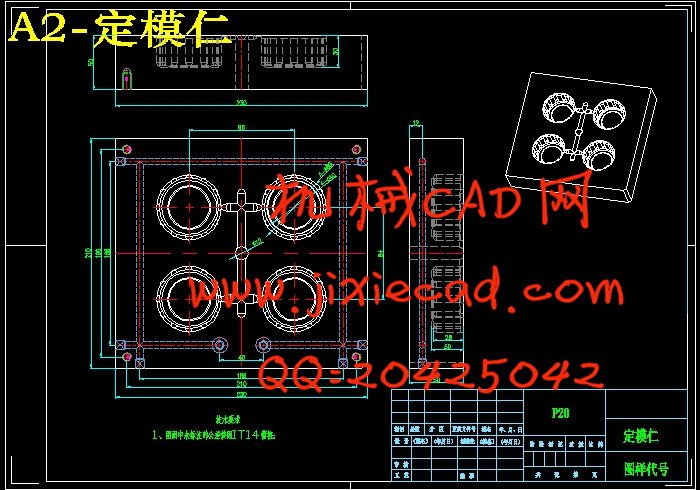

6.2.1 定模型腔尺寸计算 31

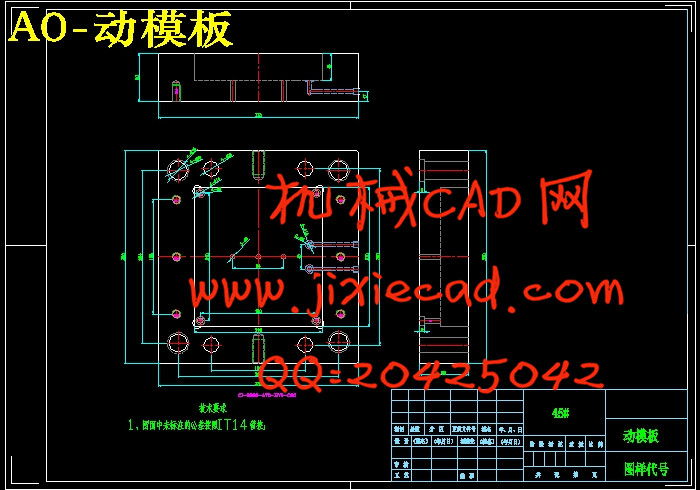

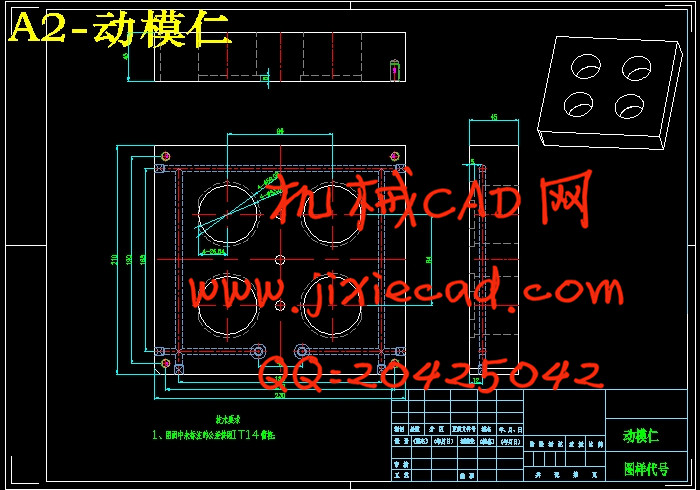

6.2.2动模型芯尺寸计算 32

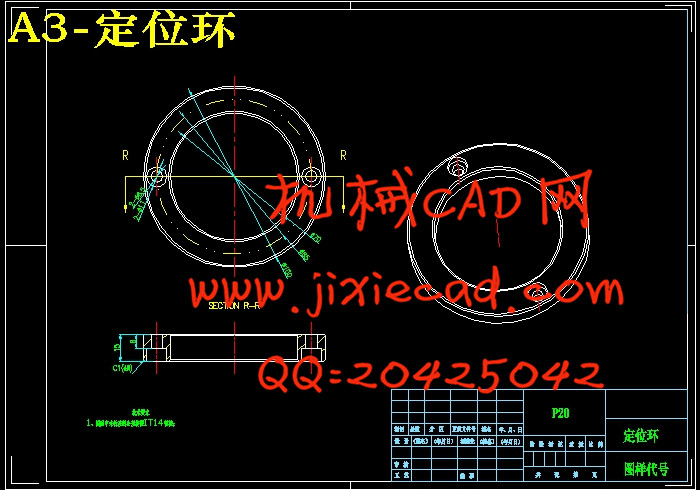

第7章 合模导向和定位机构设计 35

7.1 合模导向和定位机构设计 35

8.1 脱模机构的设计 36

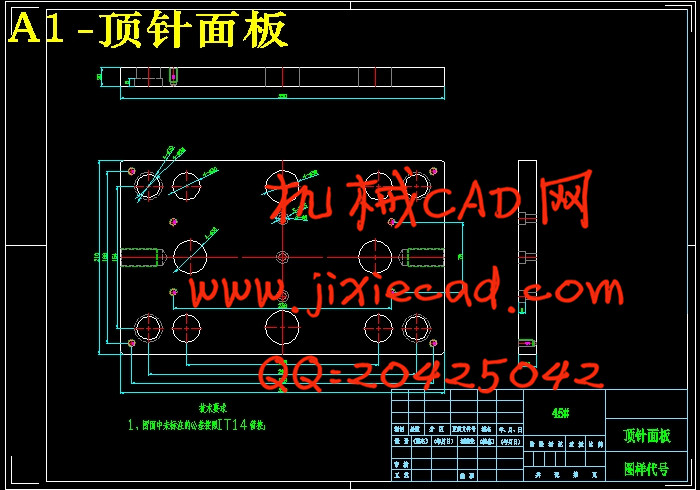

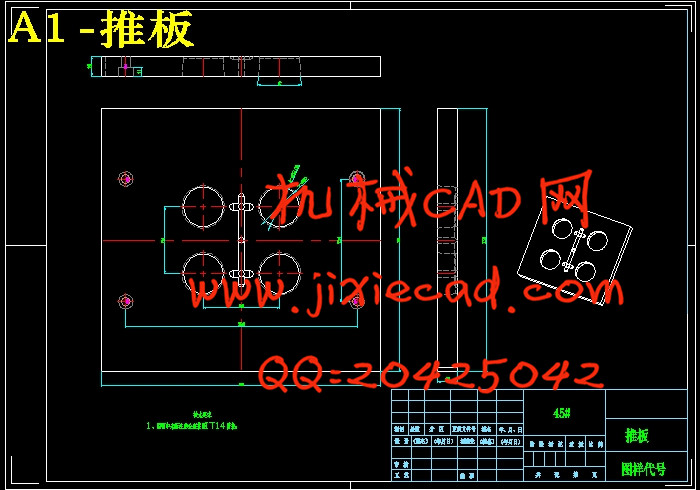

8.2 推板设计 38

第9章 模具冷却系统 41

9.1 冷却水管管道的设置 41

第10章 支承与连接零件的设计与选择 42

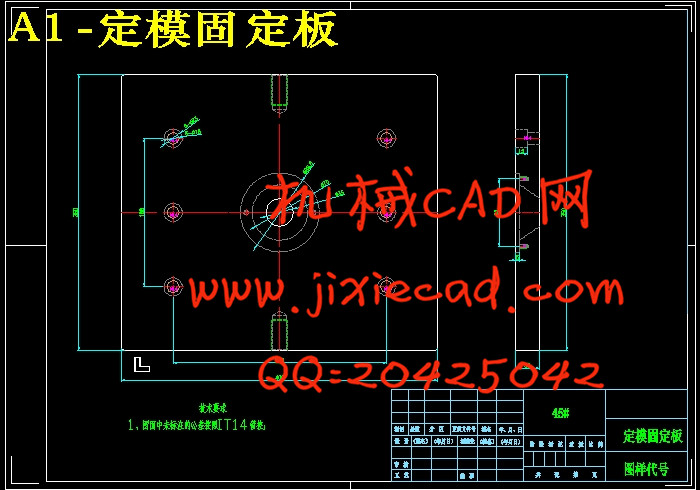

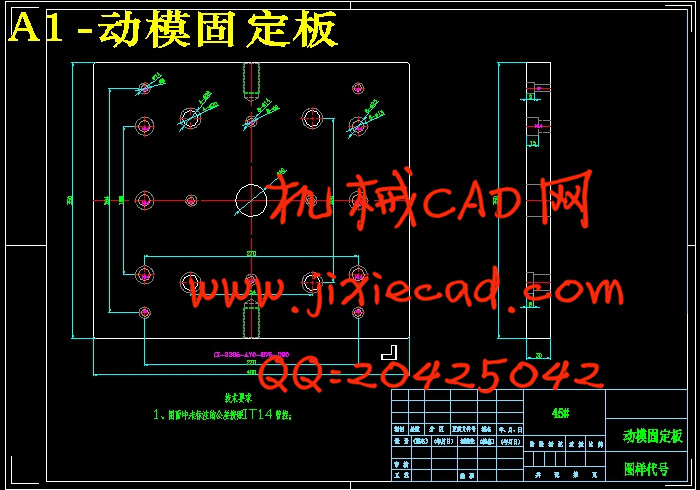

10.1 固定板 42

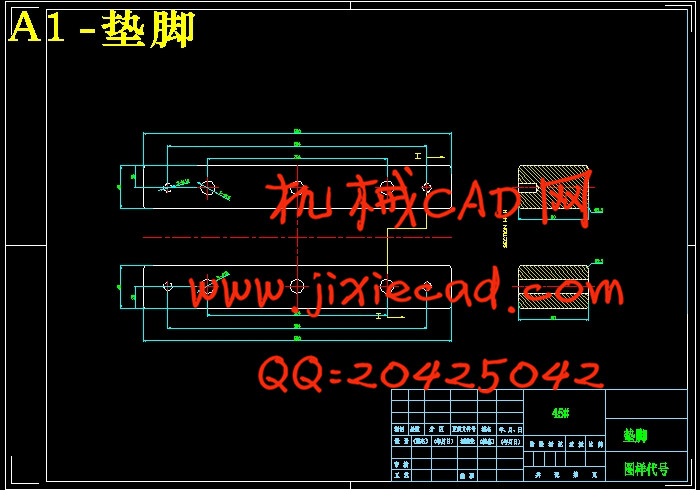

10.2 支承板和垫块 43

10.3模座 43

结 论 44

参考文献 46