设计简介

摘 要

随着高性能工程塑料的不断发展,各种塑料制品行业,该行业需要继续增长,注射成型工艺越来越多地用于成形制造的产品的各种性能要求。注射模具设计的质量,对注射机的生产效率直接影响成型,产品的质量和成本。模具可以是一个很好的注射成型上百万次,因为其较长的寿命,在另一方面,降低了塑件的成型和模具成本,作为一个结果,一个好的更换,维修少,从而提高生产效率。为了满足日益增长的工业需求和生活质量的需要,应继续研究和开发,已被设计来提高注射模具的性能,满足各行各业的需求。在本设计中,通过对对汽车内饰标识罩,CAD模具设计和开发利用包括凸,凹模的设计,顶出机构的设计,注射机的选择和校核,浇注系统的设计,冷却系统的设计,模具及其他工作选择。在本设计中,重点设计了以成形件的凸,凹模的设计,浇注系统,冷却系统。浇注系统是模具设计的灵魂和冷却设计,浇注系统的设计直接影响着塑件的成型质量和生产效率。因此,浇注系统的设计是注射模具设计工作的关键。同时,模具温度对塑件的质量和生产效率有着直接的影响,对模具的凝固时间和收缩应力,模具温度的控制直接影响,从而影响模具和塑料件质量的成型周期,和表面粗糙度。大小的凸,凹模尺寸,浇注系统和冷却系统的设计重点和系统结构设计。通过这样的设计,我们首先学习了解当前的形势和发展情况,中国塑料模具结构和成型工艺的模具及注射模具设计的基本原理。

关键词:汽车内饰标识罩;注射模;设计;PP

Abstract

With the development of high performance engineering plastics, plastic products industry, the industry needs to continue to grow, the injection molding process is more and more used in various performance requirements of the product manufacturing. The quality of injection mold design, the injection molding machine production efficiency directly affects molding, product quality and cost. Mold can be a very good injection molding millions of times, because of their longer life expectancy, on the other hand, reduces the cost of molding and mold plastic parts, as a result, a good replacement, repair, thereby improving the production efficiency. In order to meet the growing needs of the industry and the quality of life needs, should continue to research and development, has been designed to improve the performance of injection mold injection mold, to meet the needs of all walks of life.In this design, through the one or two point of cover on the air conditioning remote control, the design and development of CAD die comprises a convex, concave mold design, the ejection mechanism design, selection and optimization of the injection machine, the design of gating system, cooling system design, mold and other work options. In this design, designed to focus on parts of the convex, concave mold design, gating system, cooling system. The gating system is the mold design of the soul and cooling design, the design of gating system directly affects the moulding quality and production efficiency [1]. Therefore, the design of gating system is the key of the injection mold design work. At the same time, mould temperature has a direct impact on the quality of plastic parts and production efficiency, solidification time and contraction on die stress, mold temperature control of a direct impact, thus affecting the molding cycle of molds and plastic parts quality, and surface roughness. The size of the convex, concave die size, design key points and system structure design of gating system and cooling system. Through this design, we first learn to understand the situation and the current development situation, basic principle of injection mold and die design China plastic mould structure and injection molding process.

Key Words: remote base, injection mold, design, PP

目 录

摘 要 IIAbstract III

目 录 IV

第1章 绪论 1

1.1蓬勃发展的模具工业 1

1.2塑料模具工业的现状和技术的主要发展方向 1

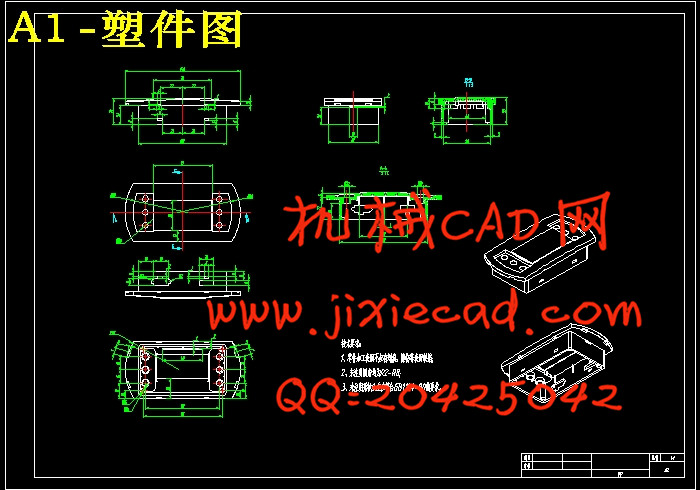

第2章 汽车内饰标识罩塑料模工艺设计 3

2.1汽车内饰标识罩塑件的工艺分析 3

2.1.1塑料材料的性能及基本成型工艺参数 3

2.1.2汽车内饰标识罩塑料的选材 4

2.1.3 PP材料成型特性 4

2.2注射成型基本过程 5

2.3汽车内饰标识罩的设计件 7

第3章 注射机的选择和校核 8

3.1注射机规格的选择 8

3.2注射机的校核 8

3.2.1注射机注射容量的校核 8

3.2.2注射机注射压力的校核 9

3.2.3注射机锁模力的校核 9

3.2.4注射机模具厚度校核注射机模具厚度校核 10

3.2.5注射机最大开模行程校核 10

3.3确定型腔数目和分模面的选择 10

3.3.1确定型腔数目 10

3.3.2分模面的选择 11

第4章 浇注系统和冷却系统设计 12

4.1浇注系统设计 12

4.1.1主流道的设计 12

4.1.2分流道的设计 12

4.1.3浇口设计 13

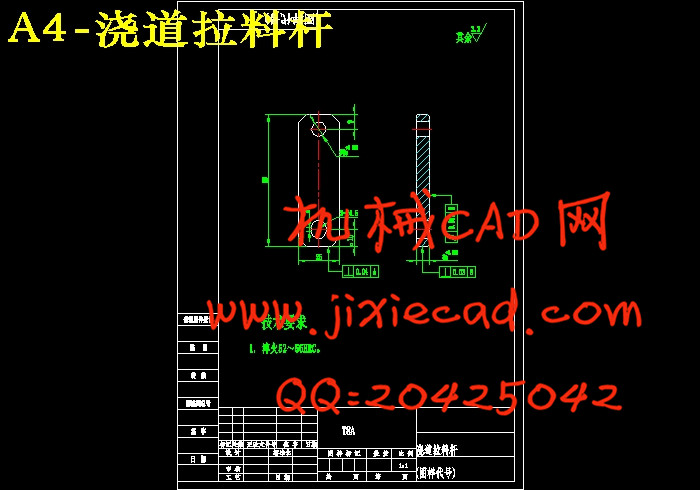

4.1.4冷料穴和拉料杆设计 14

4.1.5浇注系统的平衡 14

4.2排气系统的设计 14

4.3冷却系统设计 15

4.3.1设计冷却系统的必要性 15

4.3.2冷却系统尺寸计算 16

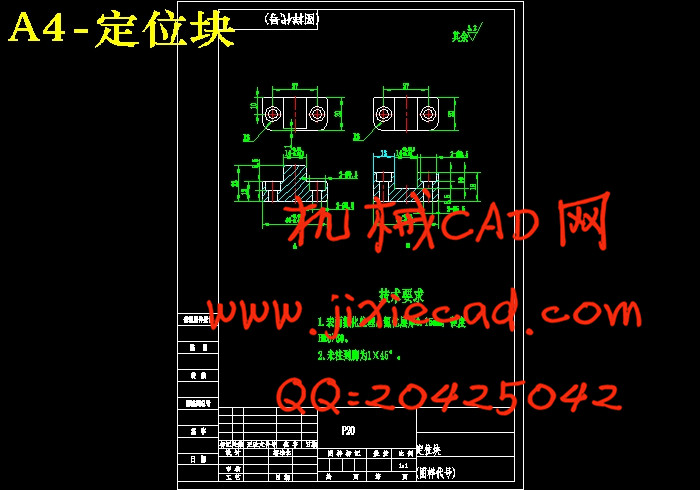

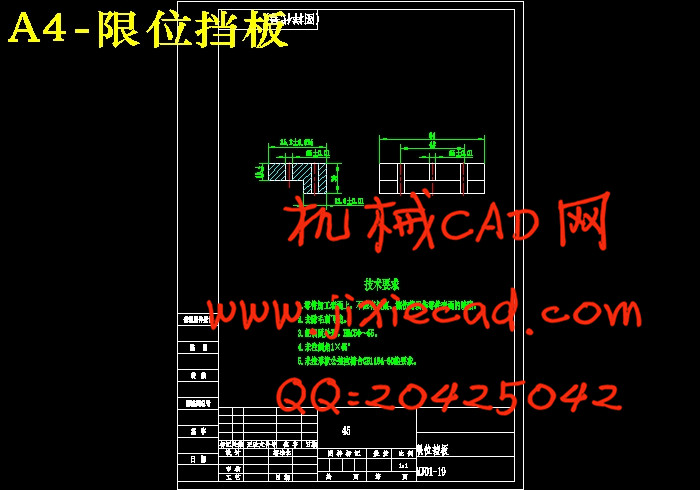

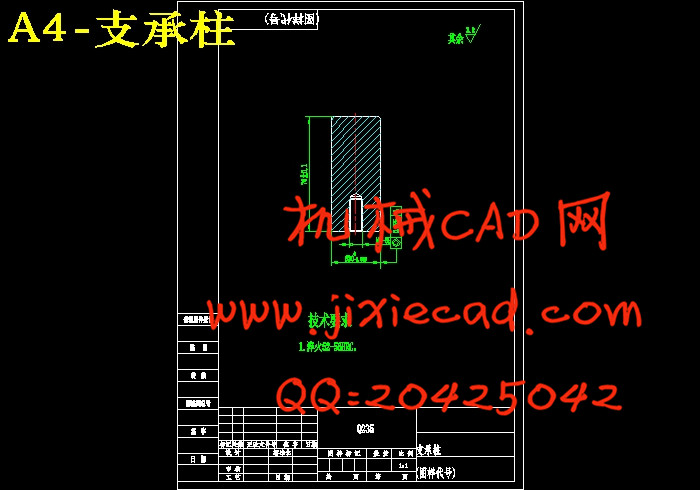

第5章 其他零部件结构设计 17

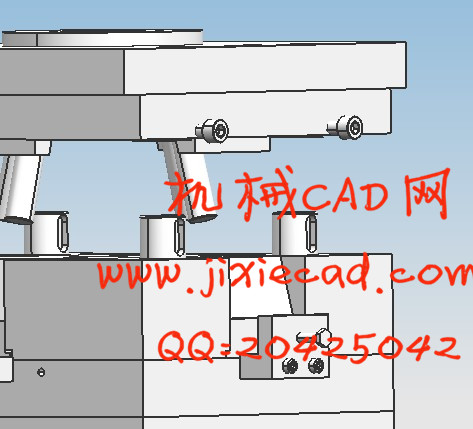

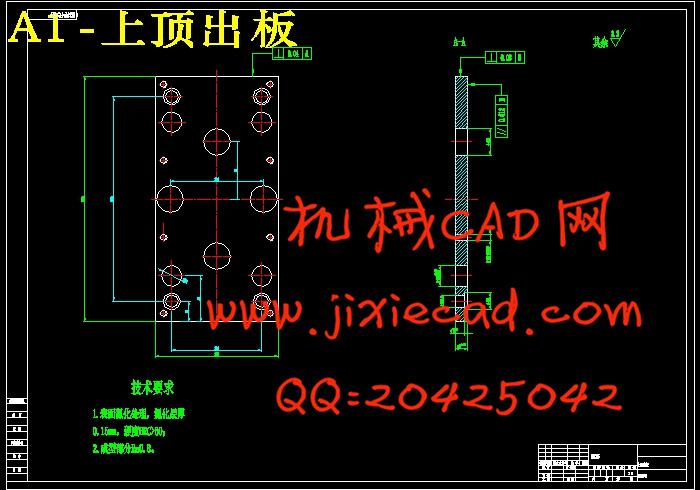

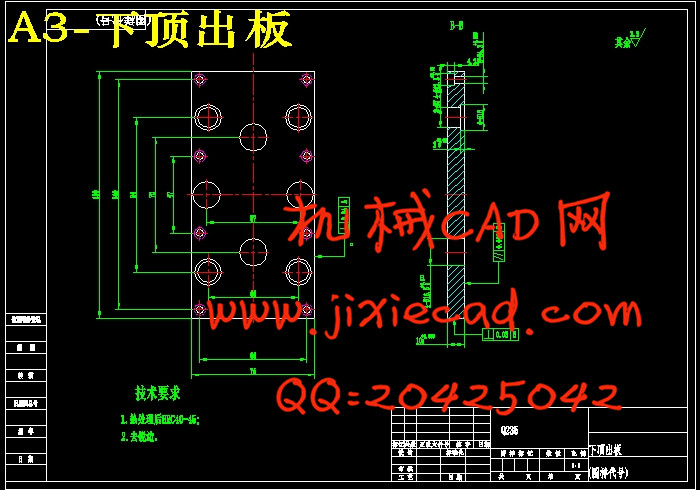

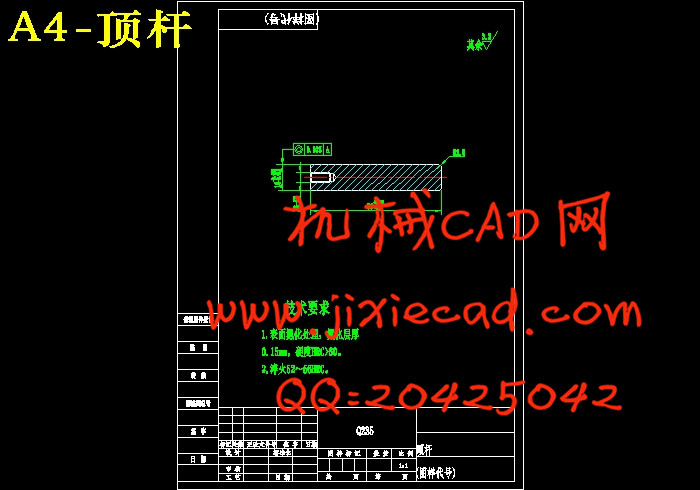

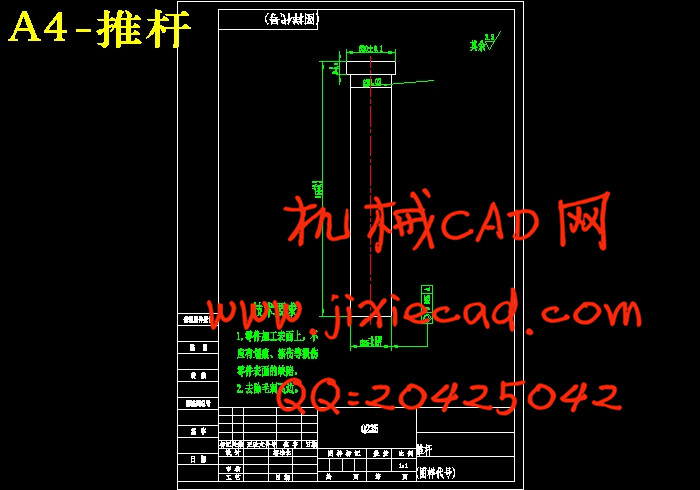

5.1脱模机构设计 17

5.1.1脱模机构的分类 17

5.1.2脱模机构设计原则 17

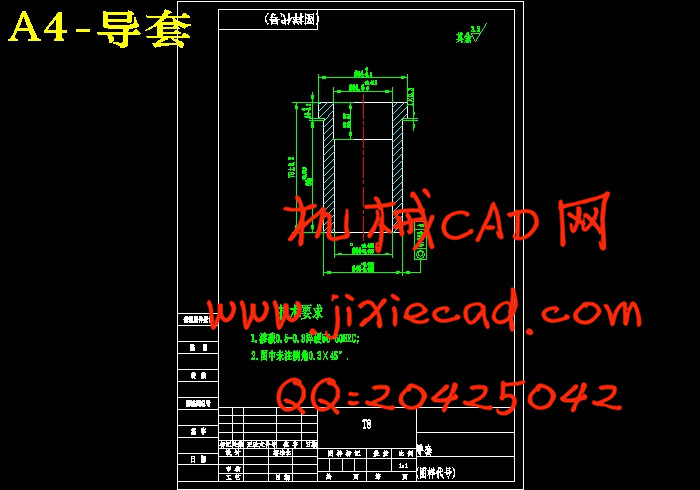

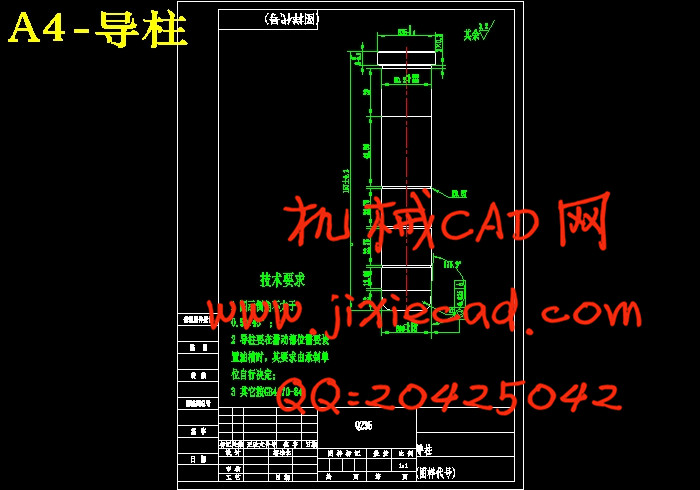

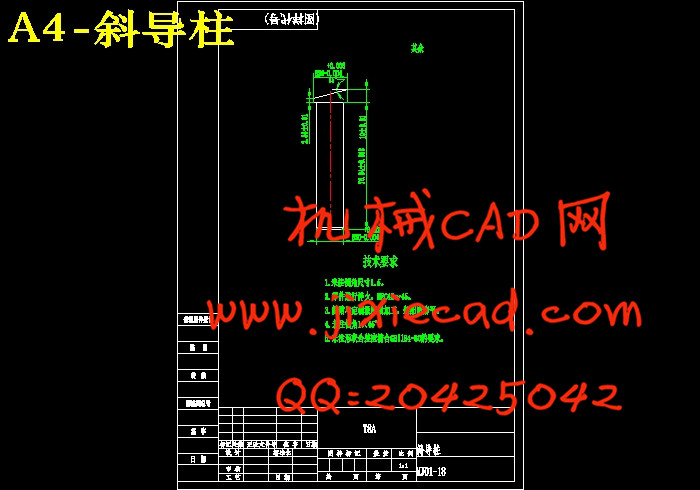

5.2导向机构设计 17

5.2.1导向机构设计原则 17

5.2.2导柱的外形尺寸计算 18

5.2.3导向孔的设计 18

5.2.4导柱的数量和布置 19

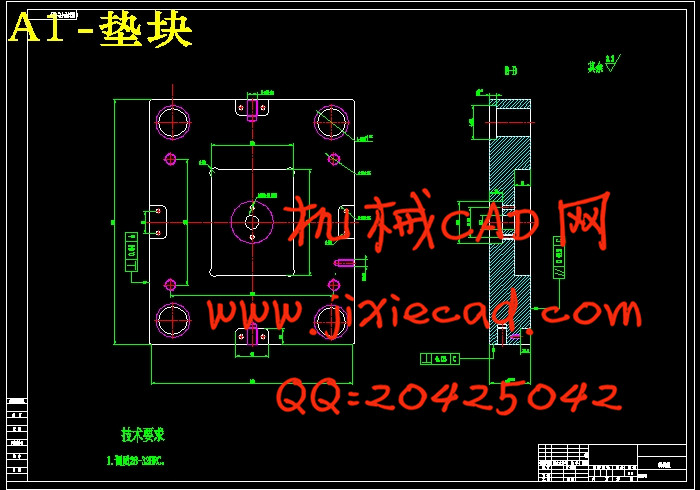

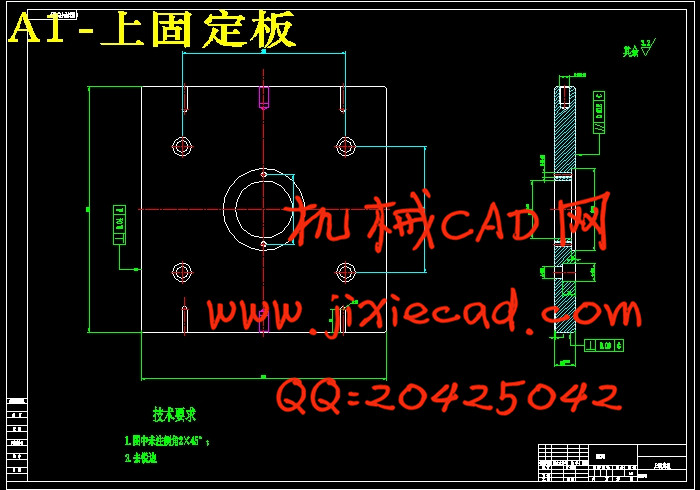

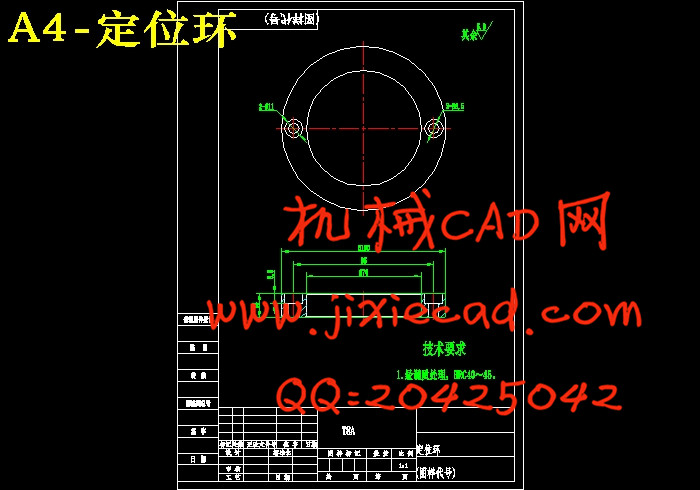

5.3定位圈 19

5.3.1定位圈的定义 19

5.3.2导柱的数量和布置 19

5.4主流道衬套 19

5.5其他结构零件设计 19

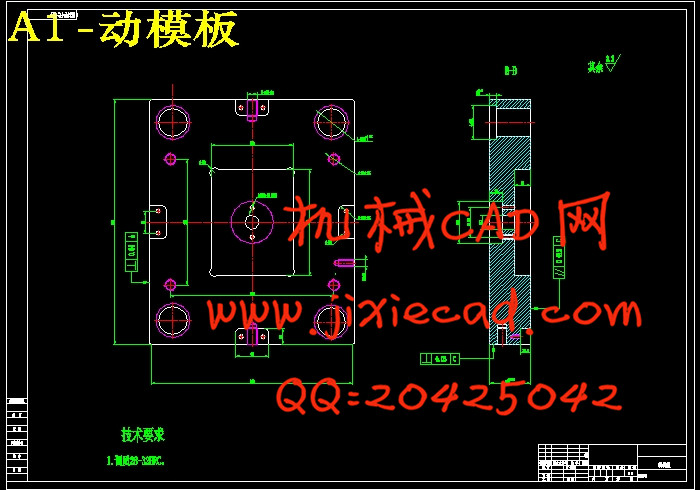

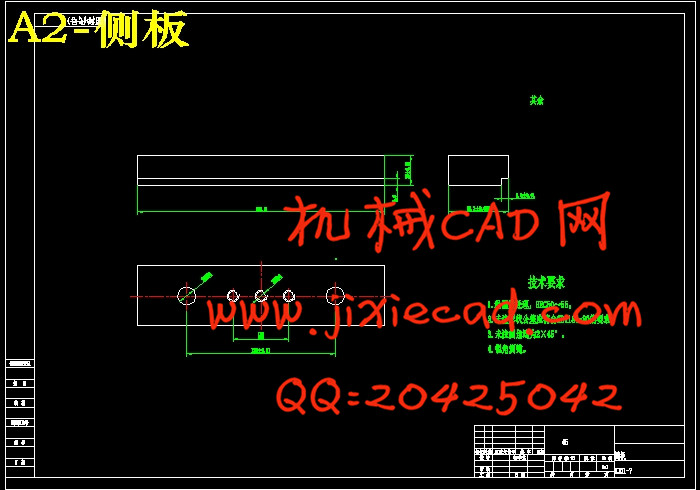

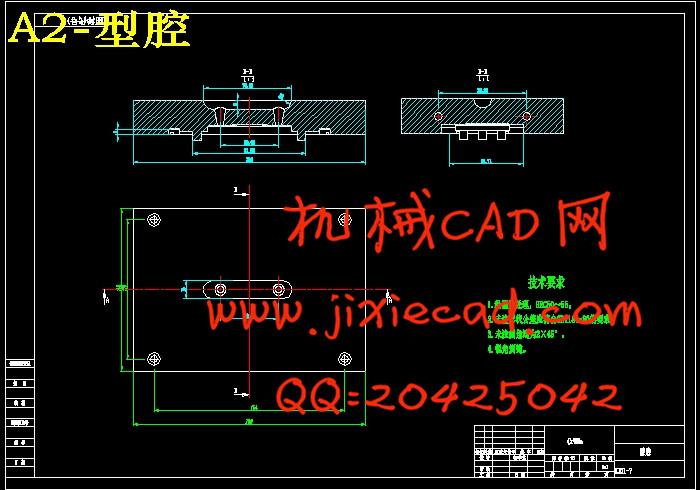

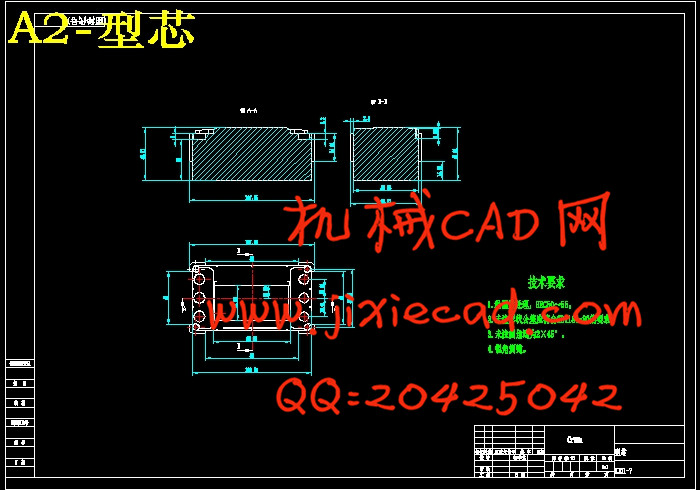

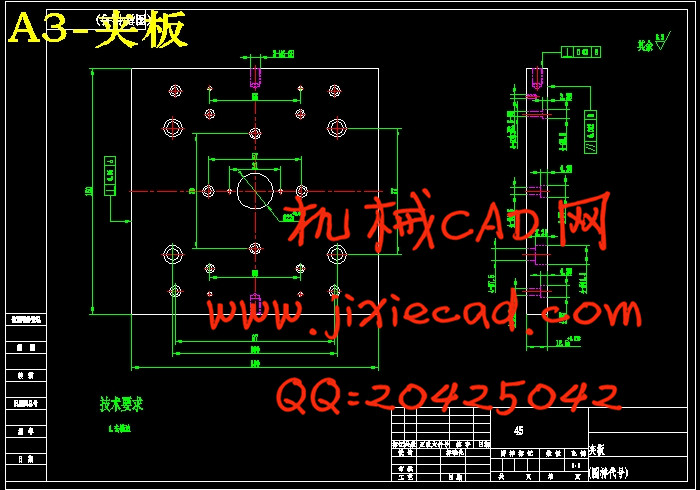

第7章 绘制模具图 21

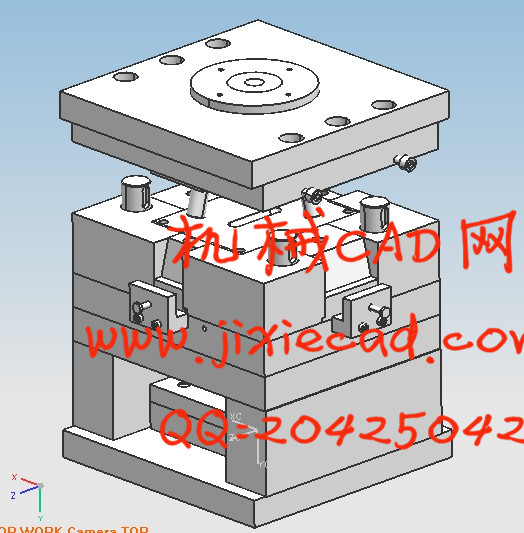

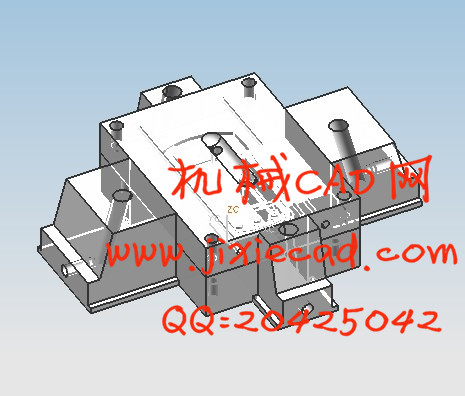

7.1 UG创建模具 21

7.2 绘制总装配结构图和部分零件图 21

结 论 22

参考文献 23

致 谢 24