设计简介

摘 要

模具工业是国民经济的基础工业,而塑料模具又是整个模具行业的霸主。我国的塑料成型模具设计,制作技术起步比较晚,整体水平还比较低,但近几年发展比较迅速。目前单单型腔的模具达80%以上,仍占主导地位。

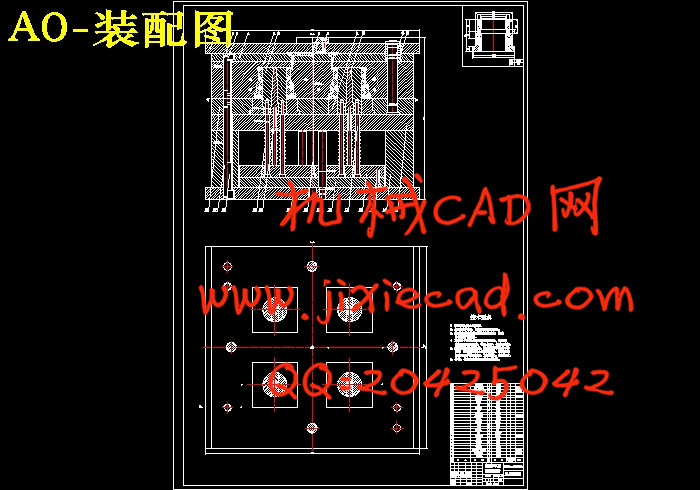

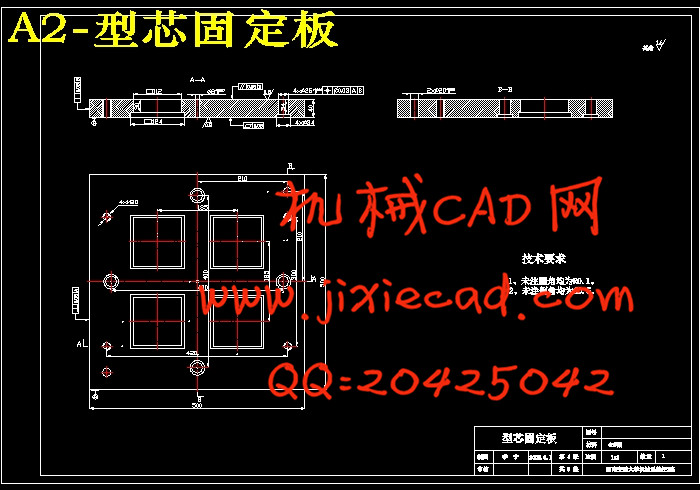

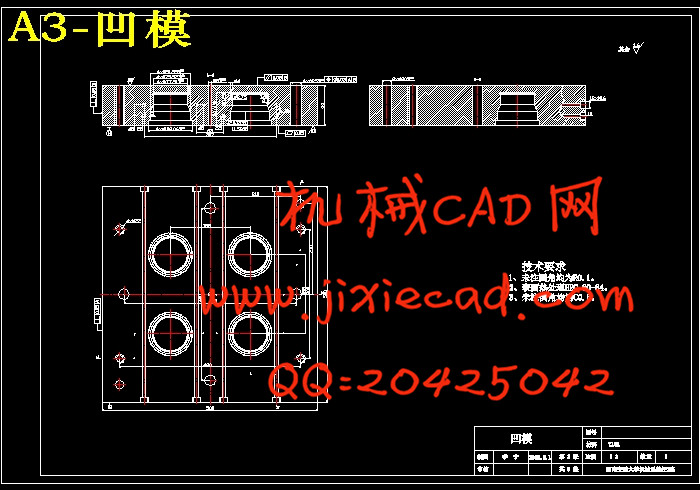

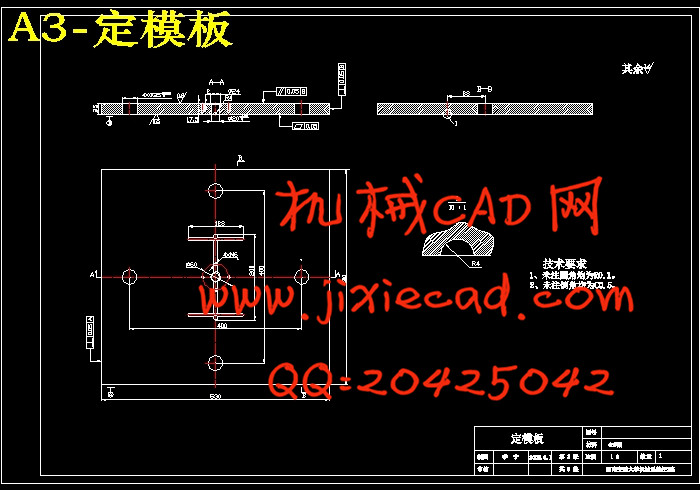

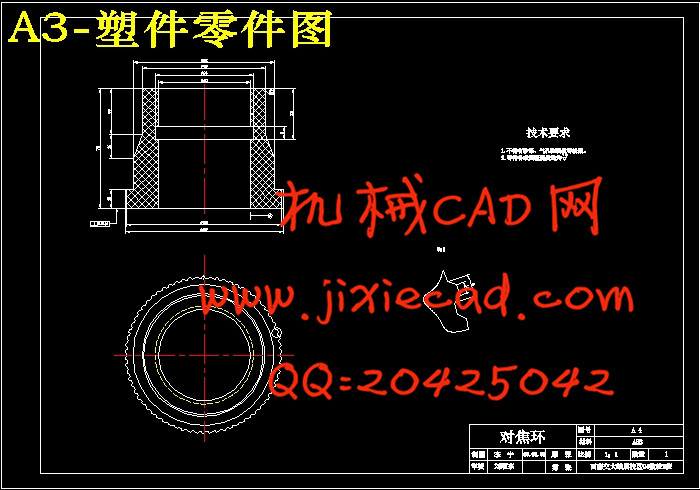

该设计通过对多种相似塑件的模具结构参考,设计的是ABS塑件模具,采用的是一模四腔注射。该产品采用环形浇口注射和组合式型腔。型腔由可活动的成形零部件组成。本论文首先简要介绍了注塑模具的结构工艺性,以及在各个行业中的应用情况,未来的发展趋势等。接着对该零件进行选材,并完成该零件的加工工艺分析。在此基础上,完成零件的体积、质量的计算、并选取注塑机以及注塑机的校核等等。根据零件图形以及精度要求,拟定出模具的结构方案,包括浇口的设计、分型面的选择、模架的选择、以及成型零件的设计等等。设计了定位销等定位零件;设计了弹簧、推杆等其它零件。设计好零件之后,对这些零件进行材料的选取,以及主要零件的加工工艺。

关键词:变焦环;注射模;环形浇口;设计

Abstract

The mold industry is the national economical foundation,and the plastic mold is the overlord in the entire mold industry. It is quite late which the development of manufacture technology, the overall level is low in our country.But the plastic mold is developing quite rapidly in plastic take- shape mold design area recent year.Now, the single cavity mold is above 80%,and still occupied an important position.

By researching many kinds of similarly models , designed a ABS model, which can inject four cavities in one time.The products are ring gated on the side,and adopt combined type cavity arrangement.The cavity is formed by the formed spare part which can move . This paper briefly introduced the craft of the injection molding, as well as the applications in the various sectors, and the development trends in the future. Then, we selected the material for the part and determinated the analysis craft .On this basis, completed the components the volume, the quality computation, and selects injection molding machine as well as injection molding machine's examination and so on. According to the components graphs as well as the accuracy requirement, draws up mold's organization plan, including the runner design, divides the profile the choice, pould frame's choice, as well as formation components design and so on. we designed the position components, like the Positioning pin; we also designed other components, like the spring、Throwout lever and so on. After the design, we selected the materials for the above components, made the processing technology for the major parts.

key words: ring of zoom leans; injection molding; ring gated; Design

模具工业是国民经济的基础工业,而塑料模具又是整个模具行业的霸主。我国的塑料成型模具设计,制作技术起步比较晚,整体水平还比较低,但近几年发展比较迅速。目前单单型腔的模具达80%以上,仍占主导地位。

该设计通过对多种相似塑件的模具结构参考,设计的是ABS塑件模具,采用的是一模四腔注射。该产品采用环形浇口注射和组合式型腔。型腔由可活动的成形零部件组成。本论文首先简要介绍了注塑模具的结构工艺性,以及在各个行业中的应用情况,未来的发展趋势等。接着对该零件进行选材,并完成该零件的加工工艺分析。在此基础上,完成零件的体积、质量的计算、并选取注塑机以及注塑机的校核等等。根据零件图形以及精度要求,拟定出模具的结构方案,包括浇口的设计、分型面的选择、模架的选择、以及成型零件的设计等等。设计了定位销等定位零件;设计了弹簧、推杆等其它零件。设计好零件之后,对这些零件进行材料的选取,以及主要零件的加工工艺。

关键词:变焦环;注射模;环形浇口;设计

Abstract

The mold industry is the national economical foundation,and the plastic mold is the overlord in the entire mold industry. It is quite late which the development of manufacture technology, the overall level is low in our country.But the plastic mold is developing quite rapidly in plastic take- shape mold design area recent year.Now, the single cavity mold is above 80%,and still occupied an important position.

By researching many kinds of similarly models , designed a ABS model, which can inject four cavities in one time.The products are ring gated on the side,and adopt combined type cavity arrangement.The cavity is formed by the formed spare part which can move . This paper briefly introduced the craft of the injection molding, as well as the applications in the various sectors, and the development trends in the future. Then, we selected the material for the part and determinated the analysis craft .On this basis, completed the components the volume, the quality computation, and selects injection molding machine as well as injection molding machine's examination and so on. According to the components graphs as well as the accuracy requirement, draws up mold's organization plan, including the runner design, divides the profile the choice, pould frame's choice, as well as formation components design and so on. we designed the position components, like the Positioning pin; we also designed other components, like the spring、Throwout lever and so on. After the design, we selected the materials for the above components, made the processing technology for the major parts.

key words: ring of zoom leans; injection molding; ring gated; Design

目 录

第1章 绪论 1

1.1 我国塑料模现状 1

1.2 塑料模发展趋势 2

第2章 制品的分析 4

2.1 制品的简介 4

2.1.1 结构分析 4

2.1.2制品的工艺性及结构的分析 4

2.2 塑件材料的分析 5

2.2.1 ABS的注射成型工艺 5

2.2.2 ABS性能分析 5

2.2.3 ABS成型塑件的主要缺陷及消除措施 7

第3章 拟订模具的结构形式 8

3.1 确定型腔数量及排列方式 8

3.1.1型腔数量的确定 8

3.1.2排列方式的确定 8

3.2 模具结构形式的确定 8

3.3 分型面位置的确定 8

3.3.1分型面的选择原则 9

3.3.2分型面的确定 9

3.4 注射机的型号和规格的选择和校核 10

3.4.1注射机的选用原则 10

3.4.2塑件体积和质量的计算 10

3.4.3注射机型号的确定 11

3.4.4需填充塑件体积的计算 11

3.4.5注射机及参数量的校核 11

3.5 浇注系统的设计 14

3.5.1主流道的设计 14

3.5.2分流道的设计 17

3.5.3浇口的设计 18

3.5.4冷料穴的设计 19

3.5.5浇注系统的平衡 20

3.6 排气系统的设计 21

3.6.1排溢设计 21

3.6.2引气设计 22

3.6.3排气设计 22

3.6.4开设排气槽应注意的问题 22

3.6.5该套模具的排气方式 22

3.7 冷却系统的设计 22

3.7.1冷却介质 23

3.7.2冷却系统的设计原则 23

3.7.3冷却装置的理论计算 23

3.8 脱模推出机构的确定 26

3.8.1脱模推出机构的设计原则 26

3.8.2制品推出的基本方式 27

3.8.3脱模力的计算 27

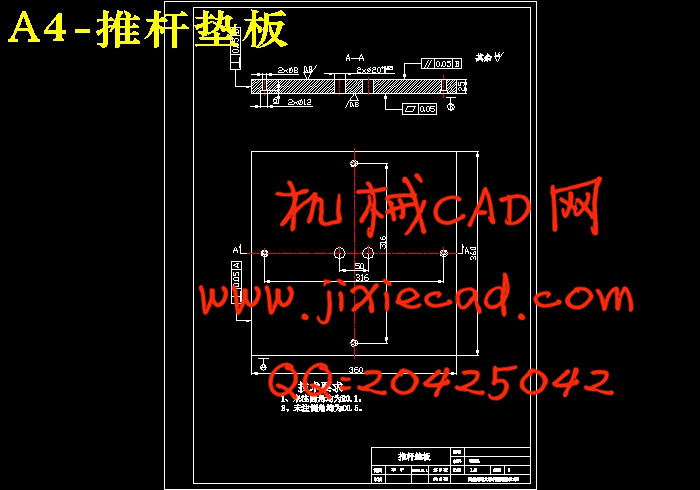

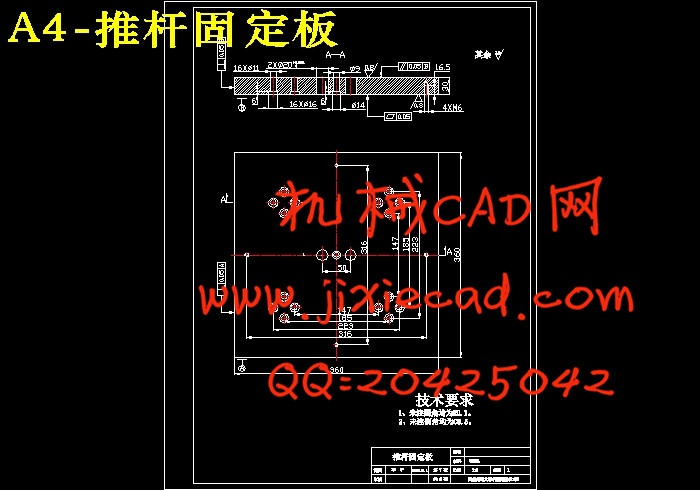

3.8.4推杆尺寸的计算 28

3.8.5推板厚度的计算 29

3.9 合模导向机构的设计 30

3.9.1导柱导向机构的设计 30

3.9.2导套的设计 31

3.10 模架的选用 32

3.10.1组合式矩形型腔侧壁厚度的计算 32

3.10.2组合式矩形型底板壁厚度的计算 33

3.10.3模架的选用 33

3.10.4模具厚度尺寸的确定 33

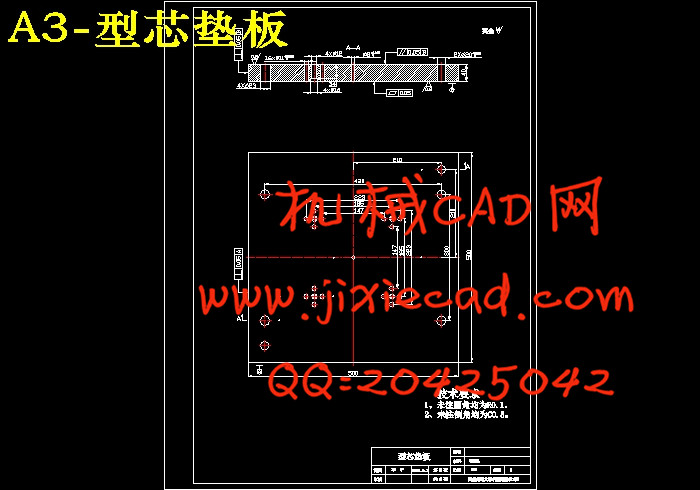

3.11 成形零件的设计 34

3.11.1影响塑件尺寸和精度的因素 35

3.11.2凹模的设计 36

3.11.3凸模的设计 39

第4章 塑料模材料的选用及技术要求 41

4.1 塑料模材料的性能要求 41

4.2 塑料模零件选材原则 41

4.3 塑料模材料的选用 41

4.3.1成型工作零件的选用 41

4.3.2本设计的材料选用 42

4.3.3该套模具所用材料的性能比较 43

4.4模具的精度要求 43

4.4.1模具零件的公差与配合选择 43

4.4.2模具与制品精度关系 43

4.4.3标准公差数值 44

4.4.4配合种类的选择 44

结论 45

致谢 46

参考文献 47