设计简介

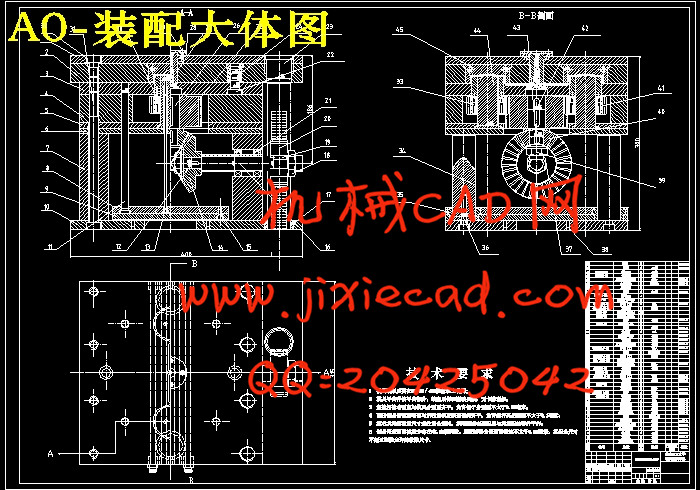

本论文根据工程实际的需要完成化妆品盒盖的注射模具设计。在设计中采用聚乙烯塑料注射而成型,成型方式为一模两腔,该论文具体分析了产品的工艺性,确定了所采用塑料的工艺参数和所采用的成型设备,确定了模具制作的总体方案,分析并解决了模具的总体结构和各工作部分的具体结构,并进行了一些必要的尺寸计算和强度的校核。该论文还对分型面、浇注系统和脱模机构进行了分析设计,完成了模具工程图设计,最后进行了主要零件加工工艺设计。

关键词 注射模 成型 工艺性 设计

Abstract

The present paper actual needs to complete according to the project accomplish the dressing case top injection molding design. Uses the polyethylene plastic injection in the design to take shape, the formation way is a mold two cavity, this paper concrete study product's technology capability, had determined uses the formation equipment which the plastic the technological parameter and uses, had determined the mold manufactures the overall concept, analyzed and has solved mold's gross structure and each effective range concrete structure, and has carried on some essential size computation and the intensity examination. This paper also halved the profile, the gating system and the mold emptier has carried on the analysis design, has completed the mold engineering plat design.

Keywords Injects the mold Formation Technology capability Design

目 录

1 引言 ……………………………………………………………………1

1.1 本研究领域的现状和国内外发展趋势 ……………………………1

1.2 本课题的研究内容.要求.目的及意义 ……………………………3

2 设计部分 ………………………………………………………………4

2.1 塑件分析 ……………………………………………………………4

2.2 塑料材料的成型特性 ………………………………………………4

2.3 设备的选择 …………………………………………………………5

2.4 浇注系统的设计 ……………………………………………………8

2.5 成型零部件的设计和计算 …………………………………………11

2.6 脱模机构的设计 ……………………………………………………16

2.7 脱螺纹机构的设计 …………………………………………………17

2.8 合模导向装置的设计 ………………………………………………25

2.9 温度调节系统的设计和计算 ………………………………………26

2.10 支承与连接零件的设计与选择……………………………………28

3 设计说明与结论 ………………………………………………………30

4 结束语 …………………………………………………………………31

致谢…………………………………………………………………………32

参考文献……………………………………………………………………33

关键词 注射模 成型 工艺性 设计

Abstract

The present paper actual needs to complete according to the project accomplish the dressing case top injection molding design. Uses the polyethylene plastic injection in the design to take shape, the formation way is a mold two cavity, this paper concrete study product's technology capability, had determined uses the formation equipment which the plastic the technological parameter and uses, had determined the mold manufactures the overall concept, analyzed and has solved mold's gross structure and each effective range concrete structure, and has carried on some essential size computation and the intensity examination. This paper also halved the profile, the gating system and the mold emptier has carried on the analysis design, has completed the mold engineering plat design.

Keywords Injects the mold Formation Technology capability Design

目 录

1 引言 ……………………………………………………………………1

1.1 本研究领域的现状和国内外发展趋势 ……………………………1

1.2 本课题的研究内容.要求.目的及意义 ……………………………3

2 设计部分 ………………………………………………………………4

2.1 塑件分析 ……………………………………………………………4

2.2 塑料材料的成型特性 ………………………………………………4

2.3 设备的选择 …………………………………………………………5

2.4 浇注系统的设计 ……………………………………………………8

2.5 成型零部件的设计和计算 …………………………………………11

2.6 脱模机构的设计 ……………………………………………………16

2.7 脱螺纹机构的设计 …………………………………………………17

2.8 合模导向装置的设计 ………………………………………………25

2.9 温度调节系统的设计和计算 ………………………………………26

2.10 支承与连接零件的设计与选择……………………………………28

3 设计说明与结论 ………………………………………………………30

4 结束语 …………………………………………………………………31

致谢…………………………………………………………………………32

参考文献……………………………………………………………………33