设计简介

摘要

模具是大批量生产时用的设备,在使用模具后,可以反复生产形状、尺寸相同的零部件。模具利用材料塑性来进行加工的,减少了切削这一加工工序,因此用模具生产可以简化工序,成本低廉,进而提高了生产效率。本次设计的塑料螺栓绝缘性好,不导电,耐酸碱性能好,因此适用于医疗器械行业、电子行业、汽车行业、家用电器、航天航空行业、石油化工工业、通讯行业、船舶行业等。

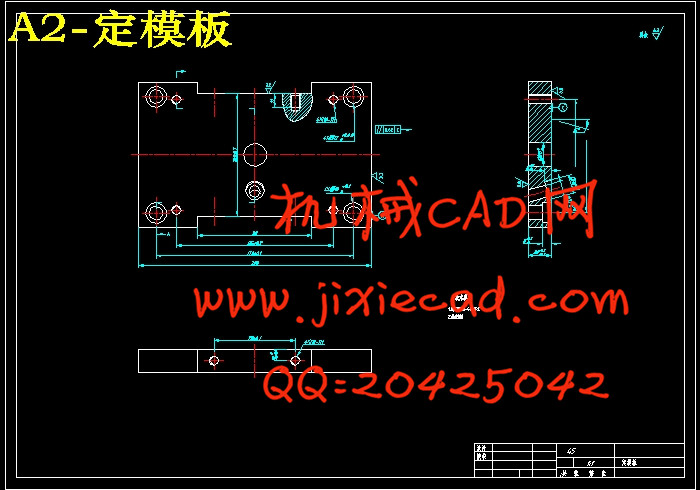

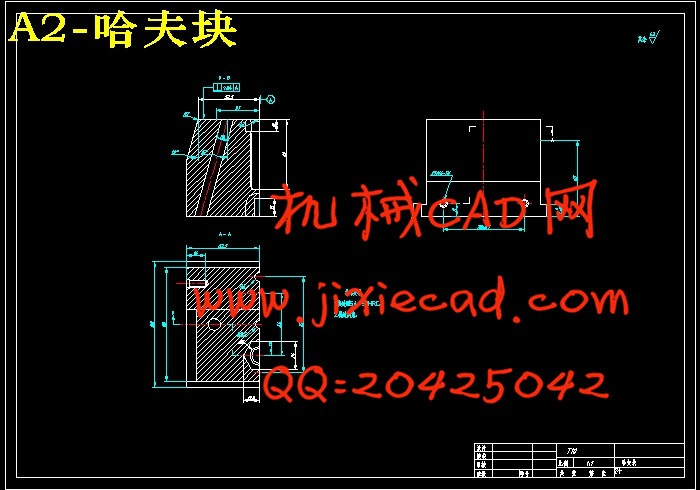

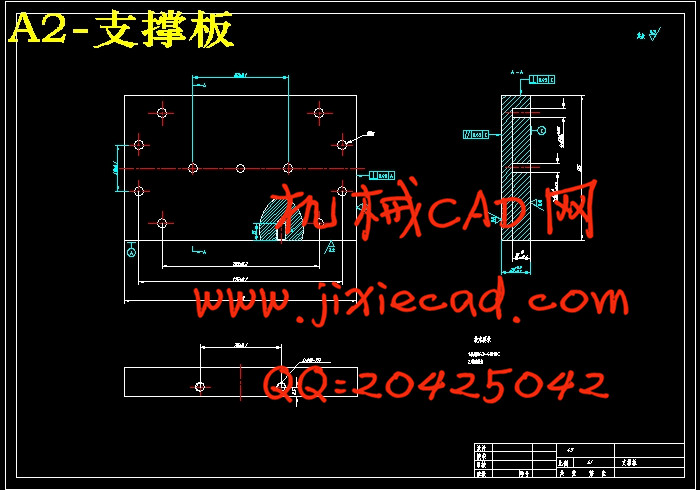

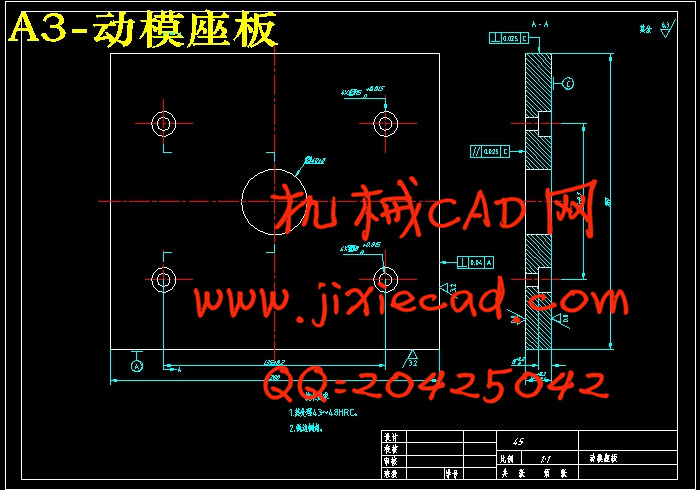

在本次塑料螺栓的注塑模设计中,通过测绘塑件,使用Pro-e设计塑料螺栓三维图,使用CAD设计塑料螺栓注塑模具装配图、成型零件图。该设计中,完成塑料螺栓的工艺性分析,凸、凹模、冷却系统、注塑模结构、浇注系统、模具零件、排气系统、脱模机构等等,一系列的设计。所有的设计中,浇注系统和冷却系统的设计是注塑成型工艺中最重要的设计,浇注系统直接对塑件的成型质量,以及塑料螺栓的生产效率产生影响;而冷却系统中的温度的设计将决定塑料熔体的固化时间以及塑料螺栓的生产效率。通过本次的塑料螺栓注塑模设计,较为全面的了解当前国内外塑料模具的现状和发展前景,掌握了塑料注塑成型的过程,注塑模具的基本结构,塑料材料的工艺成型特性。经过一系列的设计,设计出成本低廉、质量优良、生产效率高的塑料螺栓。

关键词 塑料螺栓;注射模;设计;ABS

Abstract

Mold is a mass production equipment, after the use of mold, can repeatedly produce parts of the same shape and size. Mold use throughout our daily life, as long as there are a large number of repeated production of the same products need to use the mold. The mould is processed by material plasticity, which reduces the cutting process. Therefore, the mould production can simplify the working procedure, reduce the cost and improve the production efficiency. This design of plastic bolt insulation, non-conductive, good acid and alkali resistance, so suitable for the medical equipment industry, electronics industry, automotive industry, home appliances, aerospace industry, petrochemical industry, communication Communication industry, ship industry, etc.

In the injection mould design of plastic bolt, through surveying and mapping plastic parts, using Pro-e to design 3D drawing of plastic bolt, using CAD to design assembly drawing of plastic bolt injection mould, forming part drawing.In this design, the process analysis of plastic bolt, convex, concave die, cooling system, injection mould structure, pouring system, die parts, exhaust system, demoulding mechanism and so on, a series of designs are completed.In all the design, the design of pouring system and cooling system is the most important design in the injection molding process, the casting system directly affects the molding quality of plastic parts and the production efficiency of plastic bolts.Through the design of injection mould for plastic bolt, the present situation and development prospect of plastic mold at home and abroad are comprehensively understood, the process of plastic injection molding, the basic structure of injection mould and the technological characteristics of plastic material are grasped. Through a series of designs, the plastic bolts with low cost, good quality and high production efficiency have been designed.

Keywords plastic bolt injection mold design ABS

模具是大批量生产时用的设备,在使用模具后,可以反复生产形状、尺寸相同的零部件。模具利用材料塑性来进行加工的,减少了切削这一加工工序,因此用模具生产可以简化工序,成本低廉,进而提高了生产效率。本次设计的塑料螺栓绝缘性好,不导电,耐酸碱性能好,因此适用于医疗器械行业、电子行业、汽车行业、家用电器、航天航空行业、石油化工工业、通讯行业、船舶行业等。

在本次塑料螺栓的注塑模设计中,通过测绘塑件,使用Pro-e设计塑料螺栓三维图,使用CAD设计塑料螺栓注塑模具装配图、成型零件图。该设计中,完成塑料螺栓的工艺性分析,凸、凹模、冷却系统、注塑模结构、浇注系统、模具零件、排气系统、脱模机构等等,一系列的设计。所有的设计中,浇注系统和冷却系统的设计是注塑成型工艺中最重要的设计,浇注系统直接对塑件的成型质量,以及塑料螺栓的生产效率产生影响;而冷却系统中的温度的设计将决定塑料熔体的固化时间以及塑料螺栓的生产效率。通过本次的塑料螺栓注塑模设计,较为全面的了解当前国内外塑料模具的现状和发展前景,掌握了塑料注塑成型的过程,注塑模具的基本结构,塑料材料的工艺成型特性。经过一系列的设计,设计出成本低廉、质量优良、生产效率高的塑料螺栓。

关键词 塑料螺栓;注射模;设计;ABS

Abstract

Mold is a mass production equipment, after the use of mold, can repeatedly produce parts of the same shape and size. Mold use throughout our daily life, as long as there are a large number of repeated production of the same products need to use the mold. The mould is processed by material plasticity, which reduces the cutting process. Therefore, the mould production can simplify the working procedure, reduce the cost and improve the production efficiency. This design of plastic bolt insulation, non-conductive, good acid and alkali resistance, so suitable for the medical equipment industry, electronics industry, automotive industry, home appliances, aerospace industry, petrochemical industry, communication Communication industry, ship industry, etc.

In the injection mould design of plastic bolt, through surveying and mapping plastic parts, using Pro-e to design 3D drawing of plastic bolt, using CAD to design assembly drawing of plastic bolt injection mould, forming part drawing.In this design, the process analysis of plastic bolt, convex, concave die, cooling system, injection mould structure, pouring system, die parts, exhaust system, demoulding mechanism and so on, a series of designs are completed.In all the design, the design of pouring system and cooling system is the most important design in the injection molding process, the casting system directly affects the molding quality of plastic parts and the production efficiency of plastic bolts.Through the design of injection mould for plastic bolt, the present situation and development prospect of plastic mold at home and abroad are comprehensively understood, the process of plastic injection molding, the basic structure of injection mould and the technological characteristics of plastic material are grasped. Through a series of designs, the plastic bolts with low cost, good quality and high production efficiency have been designed.

Keywords plastic bolt injection mold design ABS

目 录

摘要 I

Abstract II

1 绪论 1

1.1本课题的设计意义 1

1.2 塑料模具工业的现状和发展方向 1

1.2.1 现状 1

1.2.2发展趋势 1

2塑料螺栓的注塑模工艺设计 4

2.1螺栓塑件的工艺分析 4

2.1.1塑料材料的性能及基本成型工艺参数 4

2.1.2 塑料螺栓的选材 5

2.1.3 ABS材料成型特性 5

2.2 注塑成型基本过程 5

3注塑机的选择和校核 7

3.1注塑机规格的选择 7

3.2注塑机的校核 8

3.2.1注塑机注射容量的校核 8

3.2.2注射机注射压力的校核 8

3.2.3注射机锁模力的校核 9

3.2.4注射机模具厚度校核 9

3.2.5注射机最大开模行程校核 9

3.3确定型腔数目和分型面的选择 10

3.3.1确定型腔数目 10

3.3.2分型面的选择 10

4浇注系统和冷却系统设计 12

4.1浇注系统设计 12

4.1.1主流道设计 12

4.1.2分流道设计 14

4.1.3浇口的设计 14

4.1.4冷料穴和拉料杆的设计 16

4.2排气系统的设计 17

4.3温度调节系统的设计 17

4.3.1温度的影响及设计要求 17

4.3.2冷却系统的设计 17

4.3.3设计冷却系统的必要性 18

4.3.4冷却系统尺寸计算 18

5其他零部件的设计 20

5.1脱模机构的设计 20

5.1.1脱模机构的分类 20

5.1.2脱模机构设计原则 20

5.2 导向机构设计 20

5.2.1导向机构设计原则 21

5.2.2导柱外形尺寸计算 21

5.2.3导向孔的设计 22

5.2.4导柱的数量和布局 22

5.3定位圈的设计 22

5.3.1定位圈的数量和布局 22

5.4注塑模具成型零件和模体的设计 22

5.4.1模具型腔的结构设计 22

5.4.2 注射模具成型零件的尺寸确定 23

5.5 注射模具的侧抽芯机构设计 25

5.51侧向分型与抽芯机构的分类 25

5.5.2注塑模具的侧抽斜导柱抽芯机构设计 24

5.6模架的选用 26

5.6.1模架的基本类型 26

5.7模具安装和调试 27

5.7.1模具的安装 27

5.7.2模具的调试 27

结论 28

致谢 29

参考文献 30